Abstract

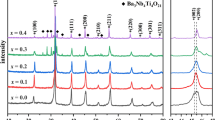

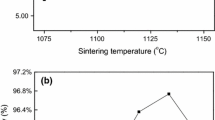

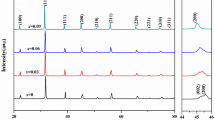

Ba (Cu1/2W1/2) O3 (BCW) ceramics were prepared and their dielectric properties were investigated for energy storage applications. A low pre-sintering temperature of 930 °C was used to achieve favorable grain crystallinity, and a sintering temperature of 1160 °C was used to obtain a high dielectric constant. A dielectric constant of 105 was observed at 10 Hz and 400 °C. Moreover, the BCW ceramics exhibited good microstructure and optimal temperature stability over a wide temperature range from − 100 to 500 °C, and the internal barrier layer capacitance mechanism was considered to be the reason for their high dielectric performance. The surfactant PEG was found to be the most effective in enhancing the dielectric properties of BCW ceramics. This study demonstrates the potential of this material for high-density energy storage applications.

Similar content being viewed by others

Date availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

H.B. Yang, L.Y. Bai, Y. Lin, F. Wang, T. Wang, Ceram. Int. 43, 2903–2909 (2017)

T.L. Yu, Z. Zhao, J.C. Li, Ceram. Int. 47, 9948–9955 (2022)

S. Peng, Y. Zhang, J.J. Tang, W.F. Zeng, C.L. Zhao, J. Mater. Sci.: Mater. Electron. 32, 23309–23316 (2021)

Y.W. Chen, M.R. Zhang, H.Y. Yang, E.Z. Li, Ceram. Int. 48, 12118–12125 (2022)

F. Li, W. Cui, Y. Shao, J. Zhang, S.M. Du, Z.L. Chen, Z.B. Tian, K.X. Chen, G.H. Liu, Mater. Chem. Phys. 287, 126365 (2022)

H. Li, P.C. Zhang, S.Q. Yu, H.Y. Yang, B. Tang, F.H. Li, S.R. Zhang, Ceram. Int. 45, 11639–11647 (2019)

P.Y. Zhao, Z.M. Cai, L.L. Chen, L.W. Wu, Y. Huan, L.M. Guo, L.T. Li, H. Wang, X.H. Wang, Energy Environ. Sci. 13, 4882–4890 (2020)

H. Palneedi, M. Peddigari, G.T. Hwang, D.Y. Jeong, J.H. Ryu, Adv. Funct. Mater. 28, 1803665 (2018)

D.X. Li, X.J. Zeng, Z.P. Li, Z.Y. Shen, H. Hao, W.Q. Luo, X.C. Wang, F.S. Song, Z.M. Wang, Y.M. Li, J. Adv. Ceram. 10, 675–703 (2021)

J.L. Li, Z.H. Shen, X.H. Chen, S. Yang, W.L. Zhou, M.W. Wang, L.H. Wang, Q.W. Kou, Y.C. Liu, Q. Li, Z. Xu, Y.F. Chang, S.J. Zhang, F. Li, Nat. Mater. 19, 999–1005 (2020)

F.E. Bouharras, M. Raihane, B. Ameduri, Prog. Mater. Sci. 113, 100670 (2020)

R. Xiang, H. Li, P.C. Zhang, X.Q. Chen, H.L. Hu, Q.Z. Wen, S.C. Liu, Ceram. Int. 47, 8447–8452 (2021)

M.K. Du, L.X. Li, L.Z. Ni, Y. Zhan, Ceram. Int. 47, 19716–19726 (2021)

K. Surendran, M. Sebastian, P. Mohanan, R. Moreira, A. Dias, Chem. Mater. 17, 142–151 (2004)

P.F. Ning, L.X. Li, P. Zhang, W.S. Xia, Ceram. Int. 38, 1391–1398 (2012)

G.H. Huang, D.X. Zhou, J.M. Xu, X.P. Chen, D.L. Zhang, W.Z. Lu, B.Y. Li, Mater. Sci. Eng.: B 99, 416–420 (2003)

C.S. Liu, X.Q. Chen, P.C. Zhang, Q.Z. Wen, L.Z. Ma, H. Li, Ceram. Int. 49, 95–100 (2023)

C.Z. Yin, C.C. Li, G.J. Yang, L. Fang, Y.H. Yuan, L.L. Shu, J. Khaliq, J. Eur. Ceram. Soc. 40, 386–390 (2020)

J. Li, Y. Tang, Z.W. Zhang, W.S. Fang, L.Y. Ao, A.H. Yang, L.J. Liu, L. Fang, J. Eur. Ceram. Soc. 41, 1317–1323 (2021)

Y. Xiong, H.Y. Xie, Z.G. Rao, L.J. Liu, Z.F. Wang, C.C. Li, J. Adv. Ceram. 10, 1360–1370 (2021)

C.Z. Yin, Z.Z. Yu, L.L. Shu, L.J. Liu, Y. Chen, C.C. Li, J. Adv. Ceram. 10, 108–119 (2020)

H.R. Tian, J.J. Zheng, L.T. Liu, H.T. Wu, H. Kimura, Y.Z. Lu, Z.X. Yue, J. Mater. Sci. Technol. 116, 121–129 (2022)

X.H. Feng, R. Liu, X.L. Xu, Y.Y. Tong, S.J. Zhang, J.C. He, J.W. Xu, X.Z. Fang, X. Wang, Chin. J. Catal. 42, 396–408 (2021)

K.A. Irshad, P. Anees, R. Rajitha, T.R. Ravindran, V. Srihari, S. Kalavathi, J. Alloys Compd. 822, 153657 (2020)

Funding

The authors gratefully acknowledge the funding of National Nature Science Foundation of China (NSFC, 51174160) and Natural Science Foundation of Shaanxi Province in China (101–221206).

Author information

Authors and Affiliations

Contributions

JW and BX: contributed to the conception and design of study. JW, BX, and XD: The materials preparation and data collection were performed. JW and BX The analysis and interpretation of data were done. BX and XD: The first draft of the manuscript were completed. JW: revised the manuscript critically for important intellectual content. All authors reviewed and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

The authors declare that there is no ethics problems.

Research data policy

These policies make it easier for researchers to share data and files that support their publications and improve author service and experience.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Xie, B. & Duan, X. Effect of sintering temperature on properties of Ba (Cu1/2W1/2) O3 high dielectric ceramics. J Mater Sci: Mater Electron 34, 1090 (2023). https://doi.org/10.1007/s10854-023-10484-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10484-w