Abstract

We herein report on compositing highly conductive GdH2 with BiCuSeO, with an aim to modulate the electronic transport and the nature of conductivity in the high-temperature regime. The incorporation of GdH2 as a minor matrix in BiCuSeO, as confirmed by structural studies, has considerably enhanced electrical conductivity in the system, thereby demonstrating the existence of thermal activation of the charge carriers. The effect of minor matrix is directly on the conversion of p-type to n-type conductivity in BiCuSeO system at near room temperature. Electronic quality factor (BE) has identified the ambiguities in the transport behaviour at near room temperature due to the addition of minor matrix. Enhancement in the power factor is seen due to GdH2, with a highest attained value of 221 μW m K−2 at 700 K for the sample with x = 11 wt%, which is nearly twice the value of pristine BiCuSeO. Highest ZT of 0.011 is obtained for the pristine BiCuSeO sample at 380 K.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Huge amount of heat gets wasted in the process of conversion of energies, leading to highly alarming environmental complications. Thus, there is a need for clean and sustainable energy resources [1]. Thermoelectric (TE) materials have been proven to give sustainable path in converting heat energy to electrical energy and vice versa [2, 3]. The performance of the thermoelectric materials is generally evaluated on the basis of a dimension-less quantity called figure of merit ZT given by

where \(S\) is the Seebeck coefficient, \(\sigma\) is the electrical conductivity, \(T\) is the absolute temperature, \({\kappa }_{\text{e}}\) is the electronic thermal conductivity and \({\kappa }_{\text{l}}\) is the lattice thermal conductivity. The term \({S}^{2} \sigma\) is known as power factor [4] which signifies the total electronic transport behaviour of a TE material. Modulating these interdependent transport properties with a perfect combination of thermal and electronic transport is essential to have greater thermoelectric performance.

Over the past decade, BiCuSeO, a multiband layered semiconductor system, is being actively studied due to its intrinsically low thermal conductivity ~ 0.9 W m−1 K−1 to 0.45 W m−1 K−1 in the temperature range 300–923 K [5, 6]. Apart from this, BiCuSeO has elements that are earth abundant and non-toxic, making it a potential candidate as a good thermoelectric material. Zhao et al. [6] compiled in a study that the BiCuSeO system performs as a decent TE material at moderate temperatures and it has been proven to be a good TE energy convertor [6,7,8] in the same temperature range (300–923 K). BiCuSeO belongs to layered 1111-type systems whose electro-physical properties can easily be tuned via dopants or introduction of secondary phases [5]. This p-type material has a tetragonal crystal structure with alternative stacking of Bi2O2 and Cu2Se2 layers along the c-axis [5, 6, 9]. Since the thermal conductivity of BiCuSeO is already low, prominence has been given for improving the electrical transport by increasing the carrier concentration. To produce high-quality samples, the various methods used are solid-state reaction, spark plasma sintering, texturing using hot-forging process, ball milling, mechanical alloying [10,11,12,13,14] and so on. Various attempts in introducing point defects such as doping in Bi sites [13, 15,16,17], co-doping and dual doping [18,19,20], 3D Modulation doping [21], has led to enhanced ZT values as well. Further, a highly efficient TE module using BiCuSeO could be developed when a considerable amount of compatibility can be achieved between both n-type and p-type materials. Several investigations have been done on n-type BiCuSeO [22, 23], nevertheless there are comparatively fewer number of studies done on both n-type and p-type BiCuSeO combined together. A p-type to n-type transition was observed in a recent work by Pan et al. [24] with doping of iron in Cu sites. Compositing with superionic conductors like Cu2Se was reported to enhance the electrical transport considerably in BiCuSeO system [25, 26]. Liu et al. [27] have reported an enhancement of electrical conductivity in BiCuSeO incorporated with LSCO nano-inclusions, which led to higher power factor and ZT. The composites with polyaniline [28] and SiC [29] were also successful in optimizing the electronic transport in BiCuSeO material. A successful attempt to convert double-doped BiCuSeO was made by Zhang et al. [23] via compositing with n-type Ag in which they witnessed a transition n-type to p-type transition at high temperatures. However, achieving a good electrical transport with a possibility of p- to n-type transport has not been highly successful.

Insertion of high electrically conductive phase into a layered material like BiCuSeO is expected to alter the transport remarkably. In the present study, we have used a rare earth-based fluorite-structured compound, GdH2 [30] as the minor matrix of the composite. There are few reports using Gd as a dopant as well as composite to enhance the thermoelectric performance [31, 32]. Hydrides of Gd like GdH2 are highly conductive with semimetallic n-type transport due to the inherent H vacancies [33]. To the best of our knowledge, there are no reports on rare earth metal–hydride composites with quaternary oxyselenide thermoelectric system. This motivated us to choose an n-type material—GdH2 a minor matrix with an aim to tune the thermoelectric performance in electrically anisotropic BiCuSeO system.

2 Experimental details

The samples of BiCuSeO/xGdH2 (x = 0, 5, 8, 11 wt%) were synthesized using conventional solid-state reaction method. Highly pure powders (3N) of Bi2O3, Bi, Cu and Se were weighed stoichiometrically and ground for 2 h using agate mortar and pestle. The obtained mixture was pelletized under uniaxial hydraulic press into rectangular pellets of dimensions 6 mm × 11 mm × 1 mm. The pellets were sealed in evacuated quartz ampoules under a high vacuum of about 10–6 mbar and sintered at 573 K for 8 h with a heating rate of 1 K per minute. The temperature was slowly increased at a rate of 1 K min−1, and pellets were soaked at 773 K for 24 h, followed by cooling at the rate of 2 K per minute. Later, BiCuSeO and 3N pure GdH2 (TAEWON SCIENTIFIC CO.LTD) were added according to the nominal weight percentage to form BiCuSeO/x GdH2 (x = 0, 5, 8, 11 wt%) composites. The metallurgical processing of the ingots are repeated with a sintering temperature of 573 K for 12 h followed by natural cooling to ensure the densification of the samples. Powder X-ray diffraction were done on the samples at room temperature with CuKα radiation to confirm the formation of phase and structure of the polycrystalline samples using Rigaku mini flex 600 X-ray diffractometer. Topographical and morphological studies were done using SEM EVO MA-18 equipped with Oxford EDAX system. Hardness test was done using Vickers microhardness tester using MMTX7 Matsuzawa CO. LTD. The Hall coefficient, carrier concentration and mobility measurements were done using van der Pauw method using the Ecopia HMS-5500 Hall measurement system. Near room temperature thermal conductivity measurements were carried out using direct pulse heat technique. The Seebeck coefficient and electrical resistivity were measured simultaneously at high temperature regime (300–730 K) using Linseis LSR-3 system [34].

3 Results and discussions

3.1 Phase formation and microstructure

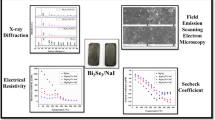

The room temperature XRD pattern of the pristine and the composites are shown in Fig. 1a. The prominent peaks of BiCuSeO/xGdH2 confirm that these polycrystalline samples have a tetragonal phase with \(P4/{\text{nmm}}\) space group (No: 129) corresponding to JCPDS card No. 45-0296 [35] and the major peaks of GdH2 (See Fig. 1b) confirm its cubical phase with space group \(Fm\overline{3 }m\) [36, 37]. Formation of single-phased BiCuSeO and GdH2 is confirmed via Rietveld analysis of XRD data. The Rietveld analysis for the samples was done using FullProf suite with Pseudo-Voigt function as the peak profile, which is the linear combination of Gaussian and Lorentzian functions. The background data can be elucidated by linear interpolation between a set background point with refinable heights. The goodness of fit parameters was in the range 1.4–1.6 and other crystallographic parameters are listed in Table 1. An additional peak was noticed with the inclusion of GdH2 minor matrix at ~ 28.64° and it is clear that the intensity of that peak increases with increase in the weight percentage. Hence, the interference of (111) plane of GdH2 in the XRD profile of BiCuSeO depicts the formation of composites involving a secondary phase. The microstructural parameters were found using two different methods viz. Scherrer equation and Size–Strain plot method (S–S) as displayed in Fig. 2. [38, 39]. Crystallite size was found in the range of 30 nm using the above said methods. The dislocation density was calculated using \(\frac{1}{{D}^{2}},\) where \(D\) is the crystallite size. Dislocation density is observed to decrease up to x = 8 wt% of GdH2 and then an increase is seen for the sample with x = 11wt%. The addition of minor matrix facilitates larger growth of crystallite domains up to 8 wt% of the composite as indicated by crystallite size and decreases for the sample with x = 11wt%.

Figure 3 presents the SEM images of the BiCuSeO/xGdH2 (x = 0, 5, 8, 11 wt%) samples. The synthesized pellets showed a dense surface morphology with not many visible pores throughout the material and the images also indicate irregular grain growth. The energy-dispersive X-ray microanalysis results ensure that all the elements of the compound are distributed evenly, confirming the homogeneity in all the samples. The EDX elemental mapping is represented in Fig. 4. The Vickers hardness test showed a hardness of 1.5 GPa for the pristine sample which is comparable with other reports [40]. With the addition of 5 wt% of GdH2, hardness reaches 2.1 GPa which is 1.4 times the pristine sample. Further addition of GdH2 reduces the hardness to 1.9 GPa and 1.5 GPa for the samples with x = 8 wt% and 11 wt%, respectively (Table 2). The microstrutural parameters along with hardness of the studied samples are presented in Table 2.

3.2 Electrical transport

Electrical resistivity of BiCuSeO/x GdH2 samples were measured in the temperature range of 310–730 K, which is depicted in Fig. 5a. The temperature dependency of electrical resistivity for pristine sample shows a typical non-degenerate semiconducting behaviour which is in good agreement with earlier reports [9, 16]. The composite samples show a different transport behaviour. Initially, the electrical resistivity of the composite samples is found to increase with temperature up to an optimum value, beyond which it decreases. Temperature dependency of composite samples show a similar trend with smooth transition from degenerate to non-degenerate type of electrical behaviour. Shifting of the peak value of resistivity towards higher temperatures with the increase in the percentage of the minor matrix was observed. Addition of high conductive GdH2 has considerably decreased the electrical resistivity at near room temperature, which is monotonic up to x = 11 wt%. To have a better insight in to the electrical transport, Hall measurements were done at room temperature and the carrier density and mobility values are listed in Table 3. Increase in the carrier density as observed by Hall measurements, clearly supports the enhanced conductivity in the composites. At room temperature, pristine and sample with x = 5 wt% were found to exhibit p-type conductivity, indicating the existence of cationic vacancies that produce acceptor levels in the material [23]. Interestingly, a negative Hall coefficient is observed in the samples with x = 8 wt% and 11wt% indicating n-type behaviour in the samples at room temperature. This can be related to the domination of donor levels contributed by n-type GdH2, that overcome the holes contributed by intrinsic Bi/Cu vacancies.

To understand the temperature dependency of resistivity, thermal activation model is used, which is given by

where \({\rho }_{0}\) is the temperature-independent constant, \({E}_{\text{A}}\) is the activation energy and \({k}_{\text{B}}\) is the Boltzmann constant. The linear relation between \(\mathrm{ln}(\rho )\) vs \(1/T\) is obtained at high temperatures above 466 K for x = 5 wt% of GdH2 and above 554 K for x = 8 wt% and 11 wt% of GdH2, which indicates the thermal activation of charge carriers at high temperature as shown in Fig. 5b. The values of activation energies are listed in Table 3.

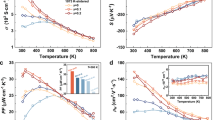

The measurement of Seebeck coefficient was done in the temperature range 310–730 K and is shown in Fig. 6a. At room temperature the Seebeck coefficient of pristine sample is observed to be 439 µV K−1 which is comparable to values reported previously [11, 41]. The addition of GdH2 caused the Seebeck coefficient to drop significantly in the composites due to the increased carrier density. Both the Seebeck coefficient and the electrical resistivity values are found to vary in a similar manner. At room temperature, positive thermopower is observed for the samples with x = 0 and 5 wt% and negative thermopower for x = 8 wt% and x = 11 wt% samples which is well supported by the Hall measurements, confirming p-type to n-type switching at higher level of GdH2 inclusions. A remarkable increase in Seebeck coefficient with increasing temperature is seen in composite samples which may be connected to the increase in density of states (DOS) near Fermi level at higher temperatures [42]. As the temperature is raised beyond 450 K, the n-type transport in the composite samples is found to disappear, which indicates the creation of hole-like point defects at higher temperatures. To have a better perception on the transport behaviour at higher temperatures, Fermi energy is evaluated (at the temperatures with Seebeck coefficient is ≥ 20 µV K−1) using an algorithm called SPBcal developed by Chang et al. [43]. The equation used to calculate Fermi energy is given by

where η is the reduced Fermi energy which is linked to Fermi energy EF as EF/kBT. F0 (η) and F1 (η) are Fermi integrals of order n = 0 and 1, respectively. Referring to Fig. 6b, the Fermi level is found to be situated below the valence band maximum (VBM) in pristine BiCuSeO sample in the entire range of temperature, clarifying the p-type degenerate electrical transport in the material. A shift from high positive to negative values of Fermi energy is witnessed in composite samples above 500 K, where all the samples exist as completely p-type degenerate.

Considering the degenerate behaviour of all the samples at near room temperature, DOS effective mass m* is estimated using Mott’s equation for diffusion thermopower which is given by

where n is the carrier density, m* is the DOS effective mass and e, ħ, and kB are electronic charge, Planck’s constant and Boltzmann constant, respectively. At room temperature, the effective mass is found to decrease from 0.99 to 0.16 me monotonically with the addition of GdH2. m* of electrons is found to be low as compared to that of holes causing low magnitudes of Seebeck coefficient at room temperature. The Lorenz number is evaluated using the approximation formula given by Kim et al. [44],

where \(S\) is the Seebeck coefficient (where \({L}_{0}\) is in 10−8 WΩ K−2 and \(S\) in µV K−1). The Lorenz number is found to vary from 1.5 to 2.4 × 10−8 WΩ K−2 as shown in the Fig. 6c. At near room temperature, all the composites have higher \({L}_{0}\) values than the pristine sample, indicating the existence of higher degeneracy of carriers. To assess the complete electrical transport of the synthesized material, weighted mobility is calculated from the formula proposed by Snyder et al. [45]

where \(h\) is the Planck’s constant, \(\sigma\) is the electrical conductivity, \(S\) is the Seebeck coefficient and \({k}_{\text{B}}\) is the Boltzmann constant. The plot of weighted mobility versus temperature is illustrated in Fig. 6d. A clear distinction, observed between the temperature-dependent weighted mobility of pristine and composite samples, signifies the changes in the scattering mechanism due to the addition of highly conductive phase in BiCuSeO. Overall, the weighted mobility of composites reduces with the addition of GdH2 up to a certain temperature. At 730 K, samples with x = 5 wt% and x = 11 wt% show higher \({\mu }_{\text{w}}\) values than the pure sample. The highest value of \({\mu }_{\text{w}}\) obtained is 15.15 cm2V−1 s−1 for the sample with x = 11 wt% of GdH2 at 730 K.

Temperature-dependent thermal conductivity (κ (T)) measurements of all the samples were performed at near room temperature range (310–380 K), which is displayed in Fig. 7. κ values of pristine BiCuSeO are found to be comparable with the previous reports [22, 35]. It is noticed that the κ values of the composites are higher than that of the pristine sample. This can be attributed to the higher thermal conductivity of GdH2. The lattice and electronic contributions to the thermal conductivity is decoupled by Wiedemann–Franz law using the temperature-dependent Lorenz factor as derived using Eq. (5) [46]. It is observed that in pristine sample, the electronic contribution is found to be less than 1%, thereby demonstrating the dominance of phonon contribution. As the secondary phase is introduced into BiCuSeO, the electronic contribution is found to grow above 5% which is mainly due to the higher charge transport in these n-type composites.

The power factor (PF) is evaluated to find the TE performance of the synthesized materials which is shown in Fig. 8a. At low temperatures, the PF of the composite samples is seen to be lower than that of the pristine sample due to the low thermopower, however, it exhibits a larger value at higher temperatures. At 700 K, the highest P.F of 221 μW m−1 K−2 was noted for x = 11 wt% of GdH2, which is higher than some of the previously reported values [17, 28] at ~ 730 K. The highest value of PF attained is approximately 2.2 times that of the pure BiCuSeO sample. The PF was obtained in the same temperature range of 310–730 K for all the samples. Zhang et al. [47] recently proposed a single material parameter ‘BE’ referred to as ‘electronic quality factor’ to access the electronic contribution to the PF. For a pair of measurements of Seebeck coefficient (S) and electrical conductivity (σ) performed simultaneously at a given temperature, it is defined as

where \({S}_{r}=\frac{\left|S\right|}{{k}_{B}/e}\). Referring to Fig. 8b, the BE values of pristine sample witness a weak dependence on temperature, whereas composite samples show a different temperature dependency. For the samples with x = 8 wt% and 11 wt%, a dip in BE values at above room temperature is clearly seen, ascribing to the ambipolar diffusion of both minority and majority carriers which reconfirm n–p-type transition. This clearly relates the competition between the intrinsic holes in BiCuSeO and the electrons contributed by GdH2 at circumscribed temperature range [48]. Above this transition, a surge in the BE values signifies the occurrence of additional charge scattering and all the samples show similar behaviour at higher temperatures (> 600 K). The figure of merit (ZT) of all the samples were evaluated in the temperature range 310–380 K and is displayed in Fig. 8c. Decrease in ZT is observed in composites samples at near room temperatures due to the lowered power factor and higher thermal conductivity. Highest ZT of 0.011 is obtained for the pure BiCuSeO sample at 380 K.

4 Conclusions

A comprehensive study was done on compositing GdH2 with BiCuSeO, synthesized by conventional solid-state reaction method. All samples are crystallized into tetragonal structure with the P4/nmm space group and addition of a secondary phase is evident from the structural studies. Addition of a highly conductive phase has considerably enhanced electrical conductivity and hence the power factor in the composite samples beyond 650 K. Seebeck coefficient and Hall measurements confirmed p-type to n-type transition for 8 and 11 wt% of GdH2 at near room temperature. The weighted mobility and power factor were found to show a similar trend. At 700 K, the highest P.F of 221 μW m−1 K−2 was observed for x = 11 wt% of GdH2, which is 2.2 times that of the pristine BiCuSeO. In this study, we have seen that the addition of composites is an effective way to tune the electrical transport in BiCuSeO system. Highest ZT of 0.011 is obtained for the pure BiCuSeO sample at 380 K. The existence of both p and n-type in a same material could be a promising way for thermoelectric device applications.

Data availability

Data will be made available on reasonable request.

References

G. Neeli, D.K. Behara, M.K. Kumar, State of the art review on thermoelectric materials. Int. J. Sci. Res. 14, 1833–1844 (2013)

D. Beretta, N. Neophytou, J.M. Hodges, M.G. Kanatzidis, D. Narducci, M. Martin-Gonzalez, M. Beekman, B. Balke, G. Cerretti, W. Tremel, A. Zevalkink, A.I. Hofmann, C. Müller, B. Dörling, M. Campoy-Quiles, M. Caironi, Thermoelectrics: from history, a window to the future. Mater. Sci. Eng. R Rep. 138, 210–255 (2019)

X.F. Zheng, C.X. Liu, Y.Y. Yan, Q. Wang, A review of thermoelectrics research—recent developments and potentials for sustainable and renewable energy applications. Renew. Sustain. Energy Rev. 32, 486–503 (2014)

H. Lee, Thermoelectrics: Design and Materials, 1st edn. (Wiley, Chichester, 2017)

A.P. Novitskii, V.V. Khovaylo, T. Mori, Recent developments and progress on BiCuSeO based thermoelectric materials. Nanobiotechnol. Rep. 16, 294–307 (2021)

L.D. Zhao, J. He, D. Berardan, Y. Lin, J.F. Li, C.W. Nan, N. Dragoe, BiCuSeO oxyselenides: new promising thermoelectric materials. Energy Environ. Sci. 7, 2900–2924 (2014)

L.D. Zhao, D. Berardan, Y.L. Pei, C. Byl, L. Pinsard-Gaudart, N. Dragoe, Bi1-xSrx CuSeO oxyselenides as promising thermoelectric materials. Appl. Phys. Lett. 97, 092118 (2010)

F. Li, J.F. Li, L.D. Zhao, K. Xiang, Y. Liu, B.P. Zhang, Y.H. Lin, C.W. Nan, H.M. Zhu, Polycrystalline BiCuSeO oxide as a potential thermoelectric material. Energy Environ. Sci. 5, 7188–7195 (2012)

S. Das, A. Ramakrishnan, M. Rudra, K.H. Chen, T.P. Sinha, D.K. Misra, R.C. Mallik, Thermoelectric properties of Zn doped BiCuSeO. J. Electron. Mater. 48, 3631–3642 (2019)

S. Das, R. Chetty, K. Wojciechowski, S. Suwas, R.C. Mallik, Thermoelectric properties of Sn doped BiCuSeO. Appl. Surf. Sci. 418, 238–245 (2017)

K. Park, D.H. Kim, H.Y. Hong, G.W. Jung, J.W. Pi, Influence of Ba2+ doping on the thermoelectric properties of BiCuSeO fabricated by spark plasma sintering. Ceram. Int. 45, 9604–9610 (2019)

J. Sui, J. Li, J. He, Y.L. Pei, D. Berardan, H. Wu, N. Dragoe, W. Cai, L.D. Zhao, Texturation boosts the thermoelectric performance of BiCuSeO oxyselenides. Energy Environ. Sci. 6, 2916–2920 (2013)

J. Lei, W. Guan, D. Zhang, Z. Ma, X. Yang, C. Wang, Y. Wang, Isoelectronic indium doping for thermoelectric enhancements in BiCuSeO. Appl. Surf. Sci. 473, 985–991 (2019)

B. Feng, G. Li, Z. Pan, H. Xiaoming, L. Peihai, H. Zhu, L. Yawei, X. Fan, Effect of synthesis processes on the thermoelectric properties of BiCuSeO oxyselenides. J. Alloys Compd. 754, 131–138 (2018)

J. Li, J. Sui, Y. Pei, C. Barreteau, D. Berardan, N. Dragoe, W. Cai, J. He, L.D. Zhao, A high thermoelectric figure of merit ZT > 1 in Ba heavily doped BiCuSeO oxyselenides. Energy Environ. Sci. 5, 8543–8547 (2012)

M. Zhang, J. Yang, Q. Jiang, L. Fu, Y. Xiao, Y. Luo, D. Zhang, Y. Cheng, Z. Zhou, Multi-role of sodium doping in BiCuSeO on high thermoelectric performance. J. Electron. Mater. 44, 2849–2855 (2015)

J. Li, J. Sui, C. Barreteau, D. Berardan, N. Dragoe, W. Cai, Y. Pei, L.D. Zhao, Thermoelectric properties of Mg doped p-type BiCuSeO oxyselenides. J. Alloys Compd. 551, 649–653 (2013)

Y. Sun, C. Zhang, C. Cao, J. Fu, L. Peng, Co-doping for significantly improved thermoelectric figure of merit in p-type Bi1-2xMgxPbxCuSeO oxyselenides. Ceram. Int. 43, 17186–17193 (2017)

G.K. Ren, S.Y. Wang, Y.C. Zhu, K.J. Ventura, X. Tan, W. Xu, Y.H. Lin, J. Yang, C.W. Nan, Enhancing thermoelectric performance in hierarchically structured BiCuSeO by increasing bond covalency and weakening carrier-phonon coupling. Energy Environ. Sci. 10, 1590–1599 (2017)

Y. Liu, L.D. Zhao, Y. Zhu, Y. Liu, F. Li, M. Yu, D.B. Liu, W. Xu, Y.H. Lin, C.W. Nan, Synergistically optimizing electrical and thermal transport properties of BiCuSeO via a dual-doping approach. Adv. Energy Mater. 6, 1–9 (2016)

Y.L. Pei, H. Wu, D. Wu, F. Zheng, J. He, High thermoelectric performance realized in a BiCuSeO system by improving carrier mobility through 3D modulation doping. J. Am. Chem. Soc. 136, 13902–13908 (2014)

Z. Zhou, X. Tan, G. Ren, Y. Lin, C. Nan, Thermoelectric properties of Cl-doped BiCuSeO Oxyselenides. J. Electron. Mater. 46, 2593–2598 (2017)

X. Zhang, D. Feng, J. He, L.D. Zhao, Attempting to realize n-type BiCuSeO. J. Solid State Chem. 258, 510–516 (2018)

L. Pan, Y. Lang, L. Zhao, D. Berardan, E. Amzallag, C. Xu, Y. Gu, C. Chen, L.D. Zhao, X. Shen, Y. Lyu, C. Lu, Y. Wang, Realization of n-type and enhanced thermoelectric performance of p-type BiCuSeO by controlled iron incorporation. J. Mater. Chem. A 6, 13340–13349 (2018)

Y. Liu, Y. Zhou, J. Lan, C. Zeng, Y. Zheng, B. Zhan, B. Zhang, Y. Lin, C.W. Nan, Enhanced thermoelectric performance of BiCuSeO composites with nanoinclusion of copper selenides. J. Alloys Compd. 662, 320–324 (2016)

H.Y. Hong, D.H. Kim, S.O. Won, J.K. Lee, S.D. Park, S.-M. Choi, S.H. Bae, K. Park, Crystal structure and thermoelectric performance of p–type Bi0.86Ba0.14CuSeO/Cu2–ySe composites. J. Mater. Res. Technol. 13, 894–905 (2021)

Y.C. Liu, J. Le Lan, B.P. Zhang, Y.H. Lin, C.W. Nan, Thermoelectric transport properties of BiCuSeO with embedded La0.8Sr0.2CoO3 nanoinclusions. Sci. China Technol. Sci. 59, 1036–1041 (2016)

B. Zheng, Y. Liu, B. Zhan, Y. Lin, J. Lan, X. Yang, Enhanced thermoelectric properties of BiCuSeO/polyaniline composites. J. Electron. Mater. 43, 3695–3700 (2014)

B. Feng, G. Li, X. Hu, P. Liu, R. Li, Y. Zhang, Y. Li, Z. He, X. Fan, Improvement of thermoelectric and mechanical properties of BiCuSeO-based materials by SiC nanodispersion. J. Alloys Compd. 818, 152899 (2020)

A. Jain, S.P. Ong, G. Hautier, W. Chen, W.D. Richards, S. Dacek, S. Cholia, D. Gunter, D. Skinner, G. Ceder, K.A. Persson, Commentary: The materials project: a materials genome approach to accelerating materials innovation. APL Mater. 1, 011002 (2013)

M. Dutta, R.K. Biswas, S.K. Pati, K. Biswas, Discordant Gd and electronic band flattening synergistically induce high thermoelectric performance in n-type PbTe. ACS Energy Lett. 6, 1625–1632 (2021)

P. Wei, B. Ke, L. Xing, C. Li, S. Ma, X. Nie, W. Zhu, X. Sang, Q. Zhang, G. Van Tendeloo, W. Zhao, Atomic-resolution interfacial structures and diffusion kinetics in Gd/Bi0.5Sb1.5Te3 magnetocaloric/thermoelectric composites. Mater. Charact. 163, 110240 (2020)

R.C. Heckman, Electrical properties of the cerium and gadolinium hydrogen systems. J. Chem. Phys. 40, 2958–2963 (1964)

K. Gurukrishna, H.R. Nikhita, S.M.M. Swamy, A. Rao, Existence of partially degenerate electrical transport in intermetallic Cu2SnSe3 thermoelectric system sintered at different temperatures. Met. Mater. Int. 28, 2023–2032 (2022)

J. Le Lan, C. Deng, W. Ma, G.K. Ren, Y.H. Lin, X. Yang, Ultra-fast synthesis and high thermoelectric properties of heavy sodium doped BiCuSeO. J. Alloys Compd. 708, 955–960 (2017)

M.G. Vergniory, L. Elcoro, C. Felser, N. Regnault, B.A. Bernevig, Z. Wang, A complete catalogue of high-quality topological materials. Nature 566, 480–485 (2019)

H. Zeng, J. Zhang, C. Kuang, In-situ reaction synthesis of pure bulk gadolinium dihydride materials. Intermetallics 18, 369–373 (2010)

S.A.A. Jabir, K.H. Harbbi, A comparative study of Williamson-Hall method and size-strain method through X-ray diffraction pattern of cadmium oxide nanoparticle. AIP Conf. Proc. 2307, 020015 (2020)

B.R. Rehani, P.B. Joshi, K.N. Lad, A. Pratap, Crystallite size estimation of elemental and composite silver nano-powders using XRD principles. Indian J. Pure Appl. Phys. 44, 157–161 (2006)

B. Feng, G. Li, Z. Pan, X. Hu, P. Liu, Y. Li, Z. He, X. Fan, Enhancing thermoelectric and mechanical performances in BiCuSeO by increasing bond covalency and nanostructuring. J. Solid State Chem. 265, 306–313 (2018)

Y. Chun Liu, Y. Hua Zheng, B. Zhan, K. Chen, S. Butt, B. Zhang, Y. Hua Lin, Influence of Ag doping on thermoelectric properties of BiCuSeO. J. Eur. Ceram. Soc. 35, 845–849 (2015)

J. Yang, G. Yang, G. Zhang, Y.X. Wang, Low effective mass leading to an improved ZT value by 32% for n-type BiCuSeO: a first-principles study. J. Mater. Chem. A 2, 13923–13931 (2014)

K. Chang, C. Liu, An algorithm of calculating transport parameters of thermoelectric materials using single band model with optimized integration methods. Comput. Phys. Commun. 247, 106875 (2020)

H.S. Kim, Z.M. Gibbs, Y. Tang, H. Wang, G.J. Snyder, Characterization of Lorenz number with Seebeck coefficient measurement. APL Mater. 3, 041506 (2015)

G.J. Snyder, A.H. Snyder, M. Wood, R. Gurunathan, B.H. Snyder, C. Niu, Weighted Mobility. Adv. mater. 32, 2001537 (2020)

K. Gurukrishna, A. Rao, Y. Chung, Y. Kuo, Manipulating the phonon transport towards reducing thermal conductivity via replacement of Cu by Mn in Cu2SnSe3 thermoelectric system. J. Solid State Chem. 307, 122755 (2022)

X. Zhang, Z. Bu, X. Shi, Z. Chen, S. Lin, B. Shan, M. Wood, A.H. Snyder, L. Chen, G.J. Snyder, Y. Pei, Electronic quality factor for thermoelectrics. Sci. Adv. 6, eabc0726 (2020)

J. Zheng, D. Wang, L.D. Zhao, An update review on N-type layered oxyselenide thermoelectric materials. Materials 14, 3905 (2021)

Acknowledgements

One of the authors (AR) acknowledges DST-FIST Grant (SR/FIST/PS-1/2017/8), Council of Scientific, and Industrial Research Grant (Sanction no: 03(1409)/17/EMR-II) for the financial support required for this work. The national science and technology council of Taiwan under grant supported the thermal conductivity measurements no: NSTC-109-2112-M-006-013.

Funding

Open access funding provided by Manipal Academy of Higher Education, Manipal. This study is supported by the DST-FIST Grant (SR/FIST/PS-1/2017/8), Council of Scientific, and Industrial Research Grant (Sanction no: 03(1409)/17/EMR-II). The national science and technology council of Taiwan under grant supported the thermal conductivity measurements no: NSTC-109-2112-M-006-013.

Author information

Authors and Affiliations

Contributions

RBB: Methodology, Formal analysis, Writing—Original Draft; KG: Conceptualization, Formal analysis, Writing—Review & Editing, Supervision; NPM: Methodology, Formal analysis; UDS: Methodology, Formal analysis; AR: Project administration, Funding acquisition, Supervision, Resources, Writing—Review & Editing; RYH—Methodology, Formal analysis; YKK—Resources; KKN: Resources.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bhoomika, R.B., Gurukrishna, K., Madhukar, N.P. et al. BiCuSeO/GdH2 thermoelectric composite: a p-type to n-type promoter with superior charge transport. J Mater Sci: Mater Electron 34, 775 (2023). https://doi.org/10.1007/s10854-023-10188-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10188-1