Abstract

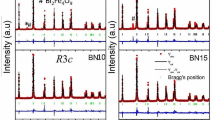

Lead-free multiferroic magnetoelectric mixed and core shell composites of BaTiO3 and NiFe2O4 were synthesised by a two-step process. The structural, morphological, electrical, magnetic and dielectric properties of the as prepared samples were investigated in detail. XRD—Rietveld refinement (using JANA 2006 program) confirms the co-existence of two phases in the composite. The dielectric, ferroelectric and ferromagnetic properties of the systems was studied. The enhanced remanent polarization of core shell composite compared to pure BaTiO3 is the direct evidence of formation of core shell structure. The decrease in saturation values of composites can be attributed to the presence of nonmagnetic BaTiO3. The magnetoelectric coupling studies on BaTiO3@NiFe2O4 core–shell system exhibits enhancement due to the well-defined interface between the two phases. The sensitivity of electric properties to the applied magnetic field enables the systems for possible applications in magnetoelectric sensors.

Similar content being viewed by others

Data availability

Data will be made available on reasonable request.

References

C.A.F. Vaz, J. Hoffman, C.H. Ahn, R. Ramesh, Adv. Mater. 22, 2900 (2010). https://doi.org/10.1002/adma.200904326

C.E. Ciomaga, L. Mitoseriu, Ferroelectric perovskite–spinel ferrite ceramics, in Magnetic, ferroelectric, and multiferroic metal oxides. ed. by B.D. Stojanovic (Elsevier, Amsterdam, 2018), pp.433–456

P. N. O, C. Zn, F. Mn., dthftfsrh (Rep, Sci, 2021). https://doi.org/10.1038/s41598-021-82399-7

P. Taylor, P. Hajra, R. Maiti, D. Chakravorty, Trans. Indian Ceram. Soc. (2013). https://doi.org/10.1080/0371750X.2011.10600149

C. Pascual-gonzalez, G. Schileo, A. Feteira, Single-phase, composite and laminate multiferroics, in Magnetic, ferroelectric, and multiferroic metal oxides. ed. by B.D. Stojanovic (Elsevier, Amsterdam, 2018), pp.457–484

W. Eerenstein, ND. Mathur, JF. Scott, Nature 442, 759 (2006). https://doi.org/10.1038/nature05023

A. Amouri, S. Aydi, N. Abdelmoula, H. Dammak, H. Khemakhem, J. Alloys Compd. (2018). https://doi.org/10.1016/jjallcom2017.12.101

J. Ma, J. Hu, Z. Li, C. Nan, Adv. Mater. (2011). https://doi.org/10.1002/adma.201003636

S. Satapathy, G. Prudhvi, A. Ali, P. Deshmukh, J. Alloys Compd. (2021). https://doi.org/10.1016/j.jallcom.2020.156960

R. Revathy, R.M. Thankachan, N. Kalarikkal, M.R. Varma, K.P. Surendran, J. Alloys Compd. (2021). https://doi.org/10.1016/j.jallcom.2021.160579

S.V. Meenakshi, R. Saravanan, N. Srinivasan, O.V. Saravanan, D. Dhayanithi, J. Electron. Mater. (2020). https://doi.org/10.1007/s11664-020-08481-4

P. Bongurala, V. Gorige, J. Magn. Magn. Mater. (2018). https://doi.org/10.1016/j.jmmm.2018.12.014

A.S. Kumar, C.S.C. Lekha, S. Vivek, V. Saravanan, K. Nandakumar, S.S. Nair, J. Magn. Magn. Mater. (2016). https://doi.org/10.1016/jjmmm2016.02.065i

S. Umashankar, T. Parida, K.R. Kumar, K.K. Bharathi, T. Parida, K.R. Kumar, A.M. Strydom, G. Markandeyulu, K. Kamala, C.M. Interactions, J. Magn. Magn. Mater. (2017). https://doi.org/10.1016/j.jmmm.2017.05.002

N.A. Spaldin, R. Ramesh, Nat. Mater. (2019). https://doi.org/10.1038/s41563-018-0275-2

D. Padmapriya, D. Dhayanithi, M.T. Rahul, N. Kalarikkal, N.V. Giridharan, Appl. Phys. A Mater. Sci. Process. 127, 1 (2021). https://doi.org/10.1007/s00339-021-04431-x

A. Chaudhuri, K. Mandal, J. Magn. Magn. Mater. 377, 441 (2015). https://doi.org/10.1016/j.jmmm.2014.10.142

R.M. Thankachan, B. Raneesh, A. Mayeen, S. Karthika, S. Vivek, S.S. Nair, S. Thomas, N. Kalarikkal, J. Alloys Compd. (2017). https://doi.org/10.1016/j.jallcom.2017.09.309

S.Y. Tan, S.R. Shannigrahi, S.H. Tan, F.E.H. Tay, J. Appl. Phys. (2010). https://doi.org/10.1063/1.2917394

A.S. Dzunuzovic, M.M.V. Petrovic, B.S. Stojadinovic, N.I. Ilic, J.D. Bobic, Ceram. Int. 41, 13189 (2015). https://doi.org/10.1016/j.ceramint.2015.07.096

R. Chauhan, R.C. Srivastava, Pramana –. J. Phys. (2016). https://doi.org/10.1007/s12043-016-1263

Y. Xue, R. Xu, Z. Wang, X. Deng, W.E.I. Cai, C. Fu (2019). https://doi.org/10.1007/s11664-019-07261-z

X. Luo, H. Wang, R. Gao, X. Li, J. Zhang, H. Ban (2020). https://doi.org/10.2298/PAC2002091L

K.C. Dhanyaprabha, B. Jacob, M. Mohan, I.A. Al-omari, S.H. Al-harthi, M.T.Z. Myint, H. Thomas, Phys. Status Solidi A (2021). https://doi.org/10.1002/pssa.202100193

M.M. Devi, A. Anand, R.K. Veena, K. Nandakumar, S. Sagar, J. Mater. Sci. Mater. Electron. 32, 27073 (2021). https://doi.org/10.1007/s10854-021-07078-9

H.M. Rietveld, J. Appl. Crystallogr. 2, 65 (1969). https://doi.org/10.1107/S0021889869006558

V. Petrícek, M. Dušek, L. Palatinus, Zeitschrift Fur Krist. 229, 345 (2014). https://doi.org/10.1515/zkri-2014-1737

B. Sarkar, S. Ramkrishna, S. Vidya, V.D. Ashok, K. Chakrabarti, J. Appl. Phys. (2014). https://doi.org/10.1063/1.4869782

K. Chand, D. Singh, S. Kumar, R.K. Kotnala, J. Alloys Compd. (2017). https://doi.org/10.1016/j.jallcom.2017.03.145

R. Ramesh, N.A. Spaldin, Nat. Mater (2007). https://doi.org/10.1038/nmat1805

K.C. Verma, R.K. Kotnala, J. Solid State Chem. (2016). https://doi.org/10.1016/j.jssc.2016.02.015

M. Cernea, B.S. Vasile, I.V. Ciuchi, V.A. Surdu, C. Bartha, A. Iuga, P. Galizia, C. Galassi, J. Mater. Sci. (2018). https://doi.org/10.1007/s10853-018-2264-x

N. Najmoddin, A. Beitollahi, H. Kavas, S. Majid, H. Rezaie, Ceram. Int (2014). https://doi.org/10.1016/j.ceramint.2013.09.063

R. Revathy, N. Kalarikkal, M.R. Varma, K.P. Surendran, J. Alloys Compd. (2021). https://doi.org/10.1016/j.jallcom.2021.161667

A.R. Abraham, B. Raneesh, S. Joseph, M. Arif, P.M.G. Nambissan, D. Das, D. Rouxel, O.S. Oluwafemi, O.S. Oluwafemi, S. Thomas, N. Kalarikkal, Phys. Chem. Chem. Phys. 21, 8709–8720 (2019). https://doi.org/10.1039/C8CP04946G

T. Woldu, B. Raneesh, B.K. Hazra, S. Srinath, P. Saravanan, M.V.R. Reddy, N. Kalarikkal, J. Alloys Compd. (2016). https://doi.org/10.1016/j.jallcom.2016.08.277

R. Grigalaitis, M.M. Vijatovi, J.D. Bobi, A. Dzunuzovic, R. Sobiestianskas, Ceram. Int (2014). https://doi.org/10.1016/j.ceramint.2013.11.069

L. Sirdeshmukh, K.K. Kumar, S.B. Laxman, A.R. Krishna, G. Sathaiah, Bull. Mater. Sci. (1998). https://doi.org/10.1007/BF02744973

P.K. Jana, S. Sarkar, B.K. Chaudhuri, J. Phys. D: Appl. Phys. (2007). https://doi.org/10.1088/0022-3727/40/2/033

A. Kumar, K.L. Yadav, Physica B (2011). https://doi.org/10.1016/j.physb.2011.02.023

C.G. Koops, Phys. Rev. (1951). https://doi.org/10.1103/PhysRev.83.121

A. Gupta, R. Chatterjee, J. Eur. Ceram. Soc. 33, 1017 (2013). https://doi.org/10.1016/j.jeurceramsoc.2012.11.003

N. Ortega, A. Kumar, R.S. Katiyar, Structural, dielectric, electrical and magnetic properties of multiferroic BaTiO3-NiFe2O4 composite ceramic. 2008 IEEE International Symposium on the Applications of Ferroelectrics IEEE (2008). https://doi.org/10.1109/ISAF.2008.4693790

A.S. Fawzi, A.D. Sheikh, V.L. Mathe, J. Alloys Compd. 493, 601 (2010). https://doi.org/10.1016/j.jallcom.2009.12.164

D.K. Pradhan, S. Kumari, P.D. Rack, Nanomaterials (2020). https://doi.org/10.3390/nano10102072

G.V. Duong, R. Groessinger, M. Schoenhart, D. Bueno-basques, J. Magn. Magn. Mater. (2007). https://doi.org/10.1016/j.jmmm.2007.03.185

M.M. Kumar, A. Srinivas, S.V. Suryanarayana, G.S. Kumar, T. Bhimasankaram, Bull. Mater. Sci. 21, 251 (1998). https://doi.org/10.1007/BF02744978

J.P. Zhou, L. Lv, Q. Liu, Y.X. Zhang, P. Liu, Sci. Technol. Adv. Mater. (2012). https://doi.org/10.1088/1468-6996/13/4/045001

Acknowledgements

The authors thank CLIF Kariavattom, and Sultan Qaboos University Oman, for providing XRD, XPS and VSM measurement facilities. The authors also thank Dr Rajeev Rawat, UGC DAE Indore centre for dielectric study and Satish Yadav for the analysis of the result. The authors are grateful to Dr Nandakumar Kalarikkal, Rahul M T and Anu A S of IIUCNN, MG University Kottayam for ME measurement and HRTEM measurement. Author K C Dhanyaprabha wishes to acknowledge Department of Science and Technology, India for the financial support under WOS-A (SR/WOS-A/PM-65/2017) scheme. Hysen Thomas acknowledge financial support received from KSCSTE under SRS project scheme (KSCSTE/1483/2019).

Funding

Funding was provided by Department of Science and Technology under women scientist scheme A (WOS-A [SR/WOS-A/PM-65/2017]) and KSCSTE under SRS project scheme (KSCSTE/1483/2019).

Author information

Authors and Affiliations

Contributions

All authors contributed and participated in conception, design, analysis and interpretation, also the final manuscript was approved by them.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dhanyaprabha, K.C., Jacob, B., Mohan, M. et al. Magnetoelectric coupling study of lead-free BaTiO3/NiFe2O4 mixed and core–shell multiferroic composites. J Mater Sci: Mater Electron 34, 207 (2023). https://doi.org/10.1007/s10854-022-09570-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-022-09570-2