Abstract

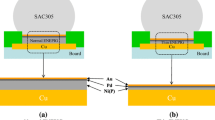

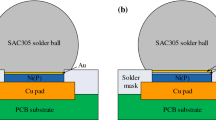

The interfacial microstructure and brittle fracture reliability of solder joints on direct electroless gold (DEG) and electroless palladium immersion gold (EPIG), which are novel surface finishes for high-frequency package substrates, were evaluated in this study. A Cu6Sn5 intermetallic compound (IMC) was formed at the interface of Sn-3.0Ag-0.5Cu (SAC305)/DEG or SAC305/EPIG, while (Cu,Ni)6Sn5 and Ni3P were formed at the interface of SAC305/ENEPIG. After 1000 h of thermal aging, the IMC thickness of the SAC305/DEG and SAC305/EPIG samples increased by 217% and by 181%, respectively, while that of SAC305/ENEPIG increased by only 51%. Although ENEPIG had the lowest IMC thickness, its brittleness was higher than that of DEG and EPIG because of the different fracture paths. Fractures occurred between Cu6Sn5/Cu pad and Cu6Sn5/Cu3Sn interface for SAC305/DEG and SAC305/EPIG, while fractures mainly occurred in the Ni3P layer of SAC305/ENEPIG.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

M. Gerber, C. Beddingfield, S. O’Connor, M. Yoo, M. Lee, D. Kang, S. Park, C. Zwenger, R. Darveaux, R. Lanzone, K. Park, Proc. Electron. Compon. Technol. Conf., 612-618 (2011). https://doi.org/10.1109/ECTC.2011.5898576

S.W. Kim, M. Detalle, L. Peng, P. Nolmans, N. Heylen, D. Velenis, A. Miller, G. Beyer, E. Beyne, Proc. Electron. Compon. Technol. Conf. (2016). https://doi.org/10.1109/ECTC.2016.205

C.F. Tseng, J.G. Duh, Mater. Sci. Eng. A 580, 169 (2013). https://doi.org/10.1016/j.msea.2013.05.058

J.W. Yoon, B.I. Noh, S.B. Jung, J. Electron. Mater. 40, 1950 (2011). https://doi.org/10.1007/s11664-011-1686-x

C.K. Huang, K.W. Lin, Y.M. Huang, A.R. Caparanga, R.B. Leron, M.H. Li, J. Electron. Mater. 42, 2648 (2013). https://doi.org/10.1007/s11664-013-2609-9

C.Y. Ho, J.G. Duh, C.W. Lin, C.J. Lin, Y.H. Wu, H.C. Hong, T.H. Wang, J. Mater. Sci. 48, 2724 (2013). https://doi.org/10.1007/s10853-012-7070-2

C.Y. Ho, J.G. Duh, Mater. Sci. Eng. A 611, 162 (2014). https://doi.org/10.1016/j.msea.2014.05.049

J.W. Yoon, J.H. Back, S.B. Jung, J. Mater. Sci. Mater. Electron. 29, 4724 (2018). https://doi.org/10.1007/s10854-017-8426-9

K. Pun, C.Q. Cui, 2009 Int. Conf. Electron. Packag. Technol. High Density Packag. ICEPT-HDP 2009 2, 1097 (2009). https://doi.org/10.1109/ICEPT.2009.5270593

P. Chi, Y. Li, H. Pan, Y. Wang, N. Chen, M. Li, L. Gao, Materials 14, 7874 (2021). https://doi.org/10.3390/ma14247874

C.E. Ho, C.W. Fan, W.Z. Hsieh, Surf. Coat. Technol. 259, 244 (2014). https://doi.org/10.1016/j.surfcoat.2014.04.027

A. Gross, N. Sitte, 20th Eur. Microelectron. Packag. Conf. EMPC 2015 13, 1 (2016)

J.H. Back, J.W. Yoon, J. Mater. Sci. Mater. Electron. 32, 24790 (2021). https://doi.org/10.1007/s10854-021-06936-w

J. Kim, J.H. Back, S.B. Jung, J.W. Yoon, J. Mater. Sci. Mater. Electron. 31, 4027 (2020). https://doi.org/10.1007/s10854-020-02950-6

X. Deng, R.S. Sidhu, P. Johnson, N. Chawla, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 36, 5–50 (2005). https://doi.org/10.1007/s11661-005-0138-8

W. Seo, K.H. Kim, Y.H. Kim, S. Yoo, J. Electron. Mater. 47, 110 (2018). https://doi.org/10.1007/s11664-017-5821-1

S.H. Kwon, K.D. Kim, D.G. Han, T.H. Sung, C.W. Lee, S. Yoo, 14th Int. Conf. Electron. Mater. Packag. EMAP 2012 5 (2012). https://doi.org/10.1109/EMAP.2012.6507909

J. Kim, S.B. Jung, J.W. Yoon, J. Alloys Compd. 805, 1013 (2019). https://doi.org/10.1016/j.jallcom.2019.07.184

J. Kim, S.B. Jung, J.W. Yoon, J. Alloys Compd. 820, 153396 (2020). https://doi.org/10.1016/j.jallcom.2019.153396

M. Ratzker, A. Pearl, M. Osterman, M. Pecht, G. Milad, J. Electron. Mater. 43, 3885 (2014). https://doi.org/10.1007/s11664-014-3322-z

S.H. Kwon, K.D. Kim, T.H. Lee, D.G. Han, T.H. Sung, C.W. Lee, S. Yoo, 14th Electron. Packag. Technol. Conf., EPTC 2012, 214 (2012). https://doi.org/10.1109/EPTC.2012.6507079

W. Seo, K.H. Kim, J.H. Bang, M.S. Kim, S. Yoo, J. Electron. Mater. 43, 4457 (2014). https://doi.org/10.1007/s11664-014-3395-8

Y.S. Wu, P.T. Lee, W.Z. Hsieh, T.T. Kuo, C.E. Ho, Surf. Coat. Technol. 359, 374 (2019). https://doi.org/10.1016/j.surfcoat.2018.12.043

C.F. Tseng, T.K. Lee, G. Ramakrishna, K.C. Liu, J.G. Duh, Mater. Lett. 65, 3216 (2011). https://doi.org/10.1016/j.matlet.2011.07.015

K. Zeng, R. Stierman, D. Abbott, M. Murtuza, 10th Inter. Conf. on Phenom. in Electron. Syst., ITHERM 2006, 1111 (2006). https://doi.org/10.1109/ITHERM.2006.1645469

P. Borgesen, L. Yin, P. Kondos, Microelectron. Reliab. 52, 1121 (2012). https://doi.org/10.1016/j.microrel.2011.12.005

L. Yin, F. Wafula, N. Dimitrov, P. Borgesen, J. Electron. Mater. 41, 302 (2012). https://doi.org/10.1007/s11664-011-1764-0

Funding

This work was supported by research funds from the Korea Institute of Industrial Technology (KITECH) (No. EO220005).

Author information

Authors and Affiliations

Contributions

All authors contributed to this work. The conception and design of the project were performed by SY. Material preparation, data collection, and analysis were performed by T-YL, JK, S-YJ, B-JA, and D-GH. The first draft of the manuscript was written by T-YL, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, TY., Kim, J., Jun, SY. et al. Interfacial microstructure and brittle fracture behavior of Sn-based solder on novel nickel-less DEG and EPIG surface finishes. J Mater Sci: Mater Electron 34, 129 (2023). https://doi.org/10.1007/s10854-022-09510-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-022-09510-0