Abstract

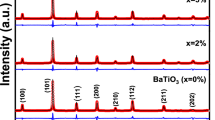

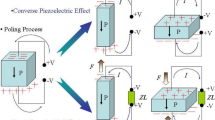

In this work, calcium barium zirconate titanate piezoelectric ceramics 0.4Ba(Zr0.2Ti0.8)O3- 0.6(Ba0.7Ca0.3)TiO3((1−x)BZT-xBCT, abbreviated as x BCZT, x = 0.6) were prepared by conventional solid state reaction method. Different surfactant additives (SDS, CTAB, PEG, and Tris–HCl, respectively) were added to the ball milling process before sintering. Meanwhile, the temperature and dwelling time during the sintering process were also systematically investigated. Their effects on the microstructural, electrical, and piezoelectric properties of the modified ceramics were investigated. It was found that with the Tris–HCl surfactant, the dispersion of the 0.6 BCZT ceramics was the best, and the average particle size was ~82 nm. By using the SDS surfactant, the ceramics showed the highest relative density, i.e., 97%. For the ferroelectric performances, the largest coercive field (Ec = 5.39 kV/cm) was observed in the sample using the SDS surfactant when the sample was sintered at 1300 °C for 6 h. For the dielectric performances, the largest dielectric constant (ε) was found to be 35,366.9 for the sample using CTAB surfactant and sintered at 1300 °C for 4 h. We discovered that CTAB-modified ceramics sintered at 1290 °C for 2 h had the highest maximum polarization Ps = 24.975 kV/cm and remnant polarization Pr = 8.200 kV/cm and sintered at 1300 °C for 4 h produced the highest piezoelectric constant d33 and dielectric constant of 94 pC/N and 35,366.7, respectively.

Similar content being viewed by others

Research data policy and data availability statements

All data generated or analyzed during this study are included in this manuscript (and its supplementary information files) or can be available from the corresponding author on reasonable request.

References

J. Lin, Y. Cao, K. Zhu et al., Ultrahigh energy harvesting properties in temperature-insensitive eco-friendly high-performance KNN-based textured ceramics. J. Mater. Chem. A 10(14), 7978–7988 (2022)

C. Long, T. Li, H. Fan et al., Li-substituted K0.5Na0.5NbO3 based piezoelectric ceramics: crystal structures and the effect of atmosphere on electrical properties. J. Alloys Compd. 658, 839–847 (2016)

L. Chen, H. Fan, Q. Li, Characterization of acceptor-doped (Ba, Ca) TiO3 “hard” piezoelectric ceramics for high-power applications. Ceram. Int. 43(7), 5579–5584 (2017)

T.R. Shrout, S.J. Zhang, Lead-free piezoelectric ceramics: alternatives for PZT? J. Electroceram. 19(1), 113–126 (2007)

H. Fan, H.E. Kim, Perovskite stabilization and electromechanical properties of polycrystalline lead zinc niobate–lead zirconate titanate. J. Appl. Phys. 91(1), 317–322 (2002)

X. Yan et al., High-performance lead-free ferroelectric BZT-BCT and its application in energy fields. J. Mater. Chem. C. 8, 13530–13556 (2020)

J. Shi, H. Fan, X. Liu et al., Large electrostrictive strain in (Bi0.5Na0.5)TiO3–BaTiO3–(Sr0.7 Bi0.2)TiO3 solid solutions. J. Am. Ceram. Soc. 97(3), 848–853 (2014)

J. Lin, Y. Wang, R. Xiong et al., Tailoring micro-structure of eco-friendly temperature-insensitive transparent ceramics achieving superior piezoelectricity. Acta Mater (2022). https://doi.org/10.1016/j.actamat.2022.118061

L. Chen, H. Fan, M. Zhang et al., Phase structure, microstructure and piezoelectric properties of perovskite (K0.5Na0.5)0.95Li0.05NbO3–Bi0.5(K0.15Na0.85)0.5 TiO3 lead-free ceramics. J Alloys Compd. 492(1–2), 313–319 (2010)

Z. Shi et al., Plate-like Ca3Co4O9: A novel lead-free piezoelectric material. Appl. Surf. Sci. (2021). https://doi.org/10.1016/j.apsusc.2020.147928

G. Clementi et al., LiNbO3 films – a low-cost alternative lead-free piezoelectric material for vibrational energy harvesters. Mech. Syst. Signal Process. 13(7), 1620–1627 (2021)

L. Kozielski et al., A large piezoelectric strain recorded in BCT ceramics obtained by a modified pechini method. Materials. 13(7), 1620–1627 (2020)

G.H. Haertling, Ferroelectric ceramics: history and technology. J. Am. Ceram. Soc. 82(4), 797–818 (2010)

J. Rodel et al., Perspective on the development of lead-free piezoceramics. J. Am. Ceram. Soc. 92(6), 1153–1177 (2009)

Q.X. Hong et al., Improved upconversion photoluminescence properties of 0.965K0.4Na0.58Li0.02Nb0.96Sb0.04O3–0.035Bi0.5K0.5ZrO3: 0.25% Er/xIn lead-free piezoelectric ceramics with balanced piezoelectric coefficient and curie temperature. J. Mater. Sci. Mater. Electron. 29(24), 20923–20930 (2018)

R. Zuo, J. Fu, Rhombohedral-tetragonal phase coexistence and piezoelectric properties of (NaK)(NbSb)O3–LiTaO3–BaZrO3 lead-free ceramics. J. Am. Ceram. Soc. 94(5), 1467–1470 (2011)

K. Wang, F.-Z. Yao, W. Jo, D. Gobeljic, V.V. Shvartsman, D.C. Lupascu, J.-F. Li, J. Rödel, Temperature-insensitive (K, Na)NbO3-based lead-free piezoactuator ceramics. Adv. Funct. Mater. 23(33), 4079–4086 (2013)

K. Xu et al., Superior piezoelectric properties in potassium–sodium niobate lead-free ceramics. Adv. Mater. 28(38), 8519–8523 (2016)

M.H. Lee et al., High-performance lead-free piezoceramics with high curie temperatures. Adv. Mater. 27, 6976–6982 (2015)

T. Takenaka, K.-i Maruyama, K. Sakata, (Bi0.5Na0.5)TiO3 BaTiO3 system for lead free piezoelectric ceramics. Jpn. J. Appl. Phys. 30(9B), 2236–2239 (1991)

C. Min et al., Structure and electrical properties of (Na0.5Bi0.5)1-xBaxTiO3 piezoelectric ceramics. J. Eur. Ceram. Soc. 28(4), 843–849 (2008)

S.T. Zhang et al., Giant strain in lead-free piezoceramics Bi0.5Na0.5TiO3-BaTiO3-K0.5Na0.5NbO3 system. Appl. Phys. Lett. 91(11), 112906 (2007)

L. Tan et al., Excellent piezoelectric performance of KNNS-based lead-free piezoelectric ceramics through powder pretreatment by hydrothermal method. J. Alloys Compd (2021). https://doi.org/10.1016/j.jallcom.2021.159770

W. Liu, X. Ren, Large piezoelectric effect in Pb-free ceramics. Phys. Rev. Lett. (2009). https://doi.org/10.1103/PhysRevLett.103.257602

Y. Zhang, H. Sun, W. Chen, A brief review of Ba(Ti0.8Zr0.2)O3-(Ba0.7Ca0.3)TiO3 based lead-free piezoelectric ceramics: past, present and future perspectives. J. Phys. Chem. Solids 114, 207–219 (2018)

W. Bai et al., Phase transition behavior and enhanced electromechanical properties in (Ba0.85Ca0.15)(ZrxTi1-x)O3 lead-free piezoceramics. Ceram. Int. 42(2), 3598–3608 (2016)

M. Acosta et al., Origin of the large piezoelectric activity in (1−x)Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 ceramics. Phys. Rev. B. (2015). https://doi.org/10.1103/PhysRevB.91.104108

D.S. Keeble et al., Revised structural phase diagram of (Ba0.7Ca0.3TiO3)-(BaZr0.2Ti0.8O3) of. Appl. Phys. Lett. 102(9), 092903 (2013)

A. Ha et al., The effect of Zn2+ and Nb5+ substitution on structural, dielectric, electrocaloric properties, and energy storage density of Ba0.95Ca0.05Ti0.95Zr0.05O3 ceramics. J. Alloys Compd. (2021). https://doi.org/10.1016/j.jallcom.2021.160355

R.L. Nayak et al., Enhanced dielectric, thermal stability, and energy storage properties in compositionally engineered lead-free ceramics at morphotropic phase boundary. Ceram. Int. 47, 17220–17233 (2021)

R. Verma et al., Structural, optical, and electrical properties of vanadium-doped, lead-free BCZT ceramics. J Alloys Compd (2021). https://doi.org/10.1016/J.JALLCOM.2021.159520

B. Rva et al., Structural, morphological, and optical properties of strontium doped lead-free BCZT ceramics—sciencedirect. Ceram. Int. 47, 15442–15457 (2021)

S.R. Reddy et al., Ferroelectric and nano-mechanical properties of the chemical solution deposited lead-free BCZT films. Mater. Sci. Eng.: B. (2021). https://doi.org/10.1016/j.mseb.2020.115037

D. Drdlik et al., A comparative study of direct and indirect evaluation of piezoelectric properties of electrophoreticaly deposited (Ba, Ca) (Zr, Ti)O3 lead-free piezoceramics. Ceram. Int. 47(2), 2034–2042 (2020)

Q. Zhang et al., Controllable synthesis of (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 submicron sphere by hydroxide Co-precipitation method. Ceram. Int. 46, 28285–28291 (2020)

E. Khomyakova et al., On the formation mechanism of Ba0.85Ca0.15Zr0.1Ti0.9O3 thin films by aqueous chemical solution deposition. J. Eur. Ceram. Soc. 40, 5376–5383 (2020)

B. Nan et al., Effect of lithium carbonate on the sintering, microstructure, and functional properties of sol–gel-derived Ba0.85Ca0.15Zr0.1Ti0.9O3 piezoceramics. J. Mater. Res. 36(5), 1105–1113 (2021)

H. Mezzourh et al., Enhancing the dielectric, electrocaloric and energy storage properties of lead-free Ba0.85Ca0.15Zr0.1Ti0.9O3 ceramics prepared via sol-gel process. Phys. B: Phys. Condens Matter. (2020). https://doi.org/10.1016/j.physb.2020.412760

C. Suryanarayana, Mechanical alloying and milling. Prog. Mater. Sci. 46, 1–184 (2001)

R.Z. Zuo et al., Sintering and electrical properties of lead-free Na0.5K0.5NbO3 piezoelectric ceramics. J. Am. Ceram. Soc. 89(6), 2010–2015 (2006)

M.T. Sebastian, H. Jantunen, Low loss dielectric materials for LTCC applications: A review. Int Mater. Rev. 53(2), 57–90 (2008)

G.D. Parfitt, Dispersion of Powders in Liquids, 3rd edn. (Applied Science Publishers, London, 1981), pp. 30–37

G. Hou, Z. Wang, F. Zhang, Sintering behavior and microwave dielectric properties of (1–x)CaTiO3−xLaAlO3 ceramics. J. Rare Earths. 29(2), 160–163 (2011)

A. James et al., Chemical synthesis, structural, thermo-physical and electrical property characterization of PLZT ceramics. J Alloys Compd. 496(1–2), 624–627 (2016)

J.F. Ihlefeld et al., Scaling effects in perovskite ferroelectrics: fundamental limits and process-structure-property relations. J. Am. Ceram. Soc. 99(8), 2537 (2016)

J. Li et al., Microstructure and dielectric properties of (Nb + In) Co-doped rutile TiO2 ceramics. J. Appl. Phys. 116(7), 61 (2014)

G. Arlt, D. Hennings, G. De With, Dielectric properties of fine-grained barium titanate ceramics. J. Appl. Phys. 58(4), 1619–1625 (1985)

X.H. Wang, R.Z. Chen, Z.L. Gui et al., The grain size effect on dielectric properties of BaTiO3 based ceramics. Mater. Sci. Eng., B 99(1–3), 199–202 (2003)

Z.M. Tian et al., Enhanced multiferroic properties in Ti-doped Bi2Fe4O9 ceramics. J. Appl. Phys. 108(6), 64110–64110 (2010)

P.A. Fuierer, R.E. Newnham, La2Ti2O7 ceramics. J. Am. Ceram. Soc. 74(11), 2876–2881 (1991)

C. Carbone, M. Benwadih, G. D’Ambrogio et al., Influence of matrix and surfactant on piezoelectric and dielectric properties of screen-printed BaTiO3/PVDF composites. Polymers 13(13), 2166 (2021)

L. Chen, H. Fan, S. Zhang, Investigation of MnO2-doped (Ba, Ca)TiO3 lead-free ceramics for high power piezoelectric applications. J. Am. Ceram. Soc. 100(8), 3568–3576 (2017)

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 51772054).

Author information

Authors and Affiliations

Contributions

JZ and YY contributed to conceptualization writing—original draft preparation; JZ, LL, WW, and YX conceived the methodology; JZ and YX helped in experiments; LL, WW, and YX were in involved in characterization; ; JZ, YY, and YX contributed to writing—review and editing; YY performed supervision; WW was involved in project administration; YY helped in funding acquisition. All the authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zeng, J., Xu, Y., Li, L. et al. Effects of surfactant additives during ball milling on the microstructural, electrical, and piezoelectric properties of 0.4Ba(Zr0.2Ti0.8)O3-0.6(Ba0.7Ca0.3)TiO3 ceramics. J Mater Sci: Mater Electron 33, 21713–21726 (2022). https://doi.org/10.1007/s10854-022-08959-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08959-3