Abstract

The co-firing compatibility between green tape and the Ag electrode is a crucial characteristic in low-temperature co-fired ceramic (LTCC) technology and plays a vital role in improving the performance and application status of LTCC device modules. In this work, we studied the effects of lead content on the glass viscosity, the microstructure, and co-firing compatibility of silver electrode film. It was found that the softening point and viscosity of the glass were decreased, and the wettability between the glass and silver was improved with the increase of the lead content, which promoted the co-firing densification and interfacial bonding between the silver electrode film and the ceramic layer. The film presented the best electrical properties co-firing at 875 °C for 15 min, with the resistivity of 1.21 mΩ/sq. And the film was densified. The sintering interface was clear and well bonded. The results showed that an appropriate lead content in glass could effectively improve the interfacial bonding and the electrical properties during co-fired process, providing a new control methodology for realizing co-fired matching of the silver electrode film with low-temperature co-fired ceramics.

Similar content being viewed by others

Data availability

The datasets generated and analyzed during the study are available from the corresponding author on reasonable request.

References

D. Wang, L. Li, M. Du, Y. Zhan, A low-sintering temperature microwave dielectric ceramic for 5G LTCC applications with ultralow loss. Ceram. Int. 47(20), 28675–28684 (2021)

B. Synkiewicz-Musialska, D. Szwagierczak, J. Kulawik, N. Pałka, P.R. Bajurko, Impact of additives and processing on microstructure and dielectric properties of willemite ceramics for LTCC terahertz applications. J. Eur. Ceram. Soc. 40(2), 362–370 (2020)

M.T. Sebastian, H. Jantunen, Low loss dielectric materials for LTCC applications: a review. Int. Mater. Rev. 53(2), 57–90 (2008)

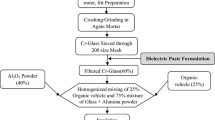

M. Liu, H. Zhou, H. Zhu, Z. Yue, J. Zhao, Microstructure and dielectric properties of glass/Al2O3 composites with various low softening point borosilicate glasses. J. Mater. Sci. Mater. Electron. 23(12), 2130–2139 (2012)

H.J. Mao, X.Y. Chen, F.L. Wang, W.J. Zhang, Effects of alkaline earth oxides on the densification and microwave properties of low-temperature fired BaO-Al2O3-SiO2 glass-ceramic/Al2O3 composites. J. Mater. Sci. 54(19), 12371–12380 (2019)

X. Luo, L. Ren, W. Xie, L. Qian, Y. Wang, Q. Sun, H. Zhou, Microstructure, sintering and properties of CaO-Al2O3-B2O3-SiO2 glass/Al2O3 composites with different CaO contents. J. Mater. Sci. Mater. Electron. 27(5), 5446–5451 (2016)

D. He, C. Gao, Effect of boron on crystallization, microstructure and dielectric properties of CBS glass-ceramics. Ceram. Int. 44(14), 16246–16255 (2018)

G.H. Chen, X.Y. Liu, Sintering, crystallization and properties of MgO-Al2O3-SiO2 system glass-ceramics containing ZnO. J. Alloys Compd. 431(1–2), 282–286 (2007)

W.J. Zhang, F.L. Wang, X.Y. Chen, H.J. Mao, Influence of La/B ratio on the structure, sinterability and crystallization of La2O3-B2O3-CaO glass-ceramics. J. Mater. Sci. Mater. Electron. 30(15), 14805–14812 (2019)

F. Wang, W. Zhang, X. Chen, H. Mao, Z. Liu, S. Bai, Low temperature sintering and characterization of La2O3-B2O3-CaO glass-ceramic/LaBO3 composites for LTCC application. J. Eur. Ceram. Soc. 40(6), 2382–2389 (2020)

X. Chen, F. Wang, W. Zhang, Low temperature sintering and dielectric properties of La2O3-B2O3-Al2O3 glass-ceramic/Al2O3 composites for LTCC applications. J. Mater. Sci. Mater. Electron. 30(15), 3098–3106 (2019)

M. Gruber, I. Kraleva, P. Supancic, R. Danzer, R. Bermejo, A novel approach to assess the mechanical reliability of thin, ceramic-based multilayer architectures. J. Eur. Ceram. Soc. 40(14), 4727–4736 (2020)

J.H. Jang, Microstructural Effects on Microwave Properties of Low-Temperature Cofired Ceramic Striplines: Experiments and Modeling. J. Am. Ceram. Soc. 87(8), 1466–1470 (2004)

C.-R. Chang, J.-H. Jean, Effects of Silver-Paste Formulation on Camber Development during the Cofiring of a Silver-Based, Low-Temperature-Cofired Ceramic Package. J. Am. Ceram. Soc. 81(11), 2805–2814 (1998)

C. Miao, M. Wang, Z. Yue, J. Zhou, Q. Li, Co-firing behavior of ZnTiO3 dielectric ceramics/Ag composites for MLCCs. Ceram. Int. 32(4), 471–474 (2006)

C.-S. Hsi, Y.-R. Chen, H.-I. Hsiang, Diffusivity of silver ions in the low temperature co-fired ceramic (LTCC) substrates. J. Mater. Sci. 46(13), 4695–4700 (2011)

M.S. Ma, Z.F. Liu, F.Q. Zhang, F. Liu, Y.X. Li, Suppression of Silver Diffusion in Borosilicate Glass-Based Low-Temperature Cofired Ceramics by Copper Oxide Addition. J. Am. Ceram. Soc. 99(7), 2402–2407 (2016)

K.C. Feng, M.W. Chu, C.H. Ku, P.Y. Chen, C.S. Tu, C.S. Chen, R.R. Chien, Y. Iizuka, Ag-diffusion inhibition mechanism in SiO2-added glass-ceramics for 5G antenna applications. Ceram. Int. 46(15), 24083–24090 (2020)

S. Kemethmuller, M. Hagymasi, A. Stiegelschmitt, A. Roosen, Viscous flow as the driving force for the densification of low-temperature co-fired ceramics. J. Am. Ceram. Soc. 90(1), 64–70 (2007)

X. Lu, H. Lin, Investigation on low-temperature reactive viscous flow sintering behavior of lanthanum-borate glass-ceramic with BaTi4O9 ceramic filler. J. Eur. Ceram. Soc. 40(12), 4035–4046 (2020)

J.-H. Jean, C.-R. Chang, Cofiring kinetics and mechanisms of an Ag-metallized ceramic-filled glass electronic package. J. Am. Ceram. Soc. 80(12), 3084–3092 (2005)

Z.R. Liu, D.D.L. Chung, Comparative study of electrically conductive thick films with and without glass. J. Electron. Mater. 33(3), 194–202 (2004)

M.I. Ojovan, Viscosity and Glass Transition in Amorphous Oxides. Adv. Condens. Matter Phys. 2008(1687–8108), 1–24 (2008)

M.I. Ojovan, K.P. Travis, R.J. Hand, Thermodynamic parameters of bonds in glassy materials from viscosity - temperature relationships. J. Phys. Condens. Matter. 19, 41 (2007)

Q.J. Zheng, J.C. Mauro, Viscosity of glass-forming systems. J. Am. Ceram. Soc. 100(1), 6–25 (2017)

T.N. Yan, W.J. Zhang, H.J. Mao, X.Y. Chen, S.X. Bai, The effect of CaO/SiO2 and B2O3 on the sintering contraction behaviors of CaO-B2O3-SiO2 glass-ceramics. Int. J. Mod. Phys. B 33(9), 1950070 (2019)

P.F. Wei, H.Q. Zhou, H.K. Zhu, B. Dai, J. Wang, Microstructure and microwave dielectric properties of CaO-B2O3-SiO2 glass ceramics with various B2O3 contents. J. Cent. South. Univ. 18(5), 1359–1364 (2011)

H. Doweidar, Y.B. Saddeek, Effect of La2O3 on the structure of lead borate glasses. J. Non Cryst. Solids 356(28–30), 1452–1457 (2010)

J. Wan, J. Cheng, P. Lu, The coordination state of B and Al of borosilicate glass by IR spectra. J. Wuhan Univ. Technol. Mater. Sci. Ed. 23(3), 419–421 (2008)

X. Zhu, C. Mai, M. Li, Effects of B2O3 content variation on the Bi ions in Bi2O3–B2O3–SiO2 glass structure. J. Non Cryst. Solids 388, 55–61 (2014)

Funding

This work was supported by the Natural Science Foundation of Hunan Province of China (Grant No. 2018JJ3602).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Zhuofeng Liu, Wenxue Liang, Weijun Zhang, Fenglin Wang, Yan Xun, Tongting Chen, Wei Li, Xingyu Chen, and Haijun Mao. The first draft of the manuscript was written by Zhuofeng Liu and Wenxue Liang. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

All authors declare that they have no conflicts of interest. The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Z., Liang, W., Zhang, W. et al. Effects of Pb–B–Si–O glass on the microstructures and electrical properties of silver electrode for LTCC application. J Mater Sci: Mater Electron 33, 17814–17827 (2022). https://doi.org/10.1007/s10854-022-08646-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08646-3