Abstract

We studied the effect of microstructural deformation on soft magnetic metal powders in a power inductor operating above 1 MHz. In this study, an inductor core was fabricated using Fe-6.5Si powders that exhibit a high electrical resistance and a large magnetic saturation value. This core was formed with a high-density microstructure using nano Fe powders synthesized via pulsed wire evaporation. The permeability was maximized at the content ratio for which the maximum density and packing fraction were observed according to the relationship between permeability and packing fraction outlined in Ollendorff’s equation. Experimentally, the highest packing fraction and permeability were observed in the core containing 20 wt% nano Fe powder. Further, the sample with the highest packing fraction showed a relatively low core loss, compared to the other samples. Thus, the inductor core is affected by the intrinsic properties and microstructure of the soft magnetic material used.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this manuscript.

References

A. Goldman, Metal Powder Cores for Telecommunications Applications, Handbook of Modern Ferromagnetic Materials, Springer US, Boston, MA, 1999: pp. 183–205. https://doi.org/10.1007/978-1-4615-4917-8_10

J.M. Silveyra, E. Ferrara, D.L. Huber, T.C. Monson, Soft magnetic materials for a sustainable and electrified world. Science 362, 2018 (1979). https://doi.org/10.1126/science.aao0195

L.O. Hultman, A.G. Jack (2003) Soft magnetic composites-materials and applications, in: IEEE International Electric Machines and Drives Conference. IEMDC’03., IEEE, https://doi.org/10.1109/IEMDC.2003.1211312

I.P. Gilbert, V. Moorthy, S.J. Bull, J.T. Evans, A.G. Jack, Development of soft magnetic composites for low-loss applications. J. Magn. Magn. Mater. (2002). https://doi.org/10.1016/S0304-8853(01)01252-5

A.W. Lotfi, M.A. Wilkowski, Issues and advances in high-frequency magnetics for switching power supplies. Proc. IEEE. 89, 833–845 (2001). https://doi.org/10.1109/5.931473

M.S. Rylko, B.J. Lyons, J.G. Hayes, M.G. Egan, Revised Magnetics Performance Factors and Experimental Comparison of High-Flux Materials for High-Current DC–DC Inductors. IEEE Trans. Power Electron. 26, 2112–2126 (2011). https://doi.org/10.1109/TPEL.2010.2103573

S. Kh. Gheisari, H. Javadpour, B. Shokrollahi, Hashemi, Magnetic losses of the soft magnetic composites consisting of iron and Ni–Zn ferrite. J. Magnetism Magn. Mater. 320, 1544–1548 (2008). https://doi.org/10.1016/j.jmmm.2008.01.005

A.K.M.A. Hossain, S.T. Mahmud, M. Seki, T. Kawai, H. Tabata, Structural, electrical transport, and magnetic properties of Ni1 – xZnxFe2O4. J. Magnetism Magn. Mater. 312, 210–219 (2007). https://doi.org/10.1016/j.jmmm.2006.09.030

J.H. Paterson, R. Devine, A.D.R. Phelps, Complex permeability of soft magnetic ferrite/polyester resin composites at frequencies above 1MHz. J. Magn. Magn. Mater. 196, 394–396 (1999). https://doi.org/10.1016/S0304-8853(98)00772-0

T. Suetsuna, S. Suenaga, K. Harada, Bulk nanogranular composite of magnetic metal and insulating oxide matrix. Scripta Mater. 113, 89–92 (2016). https://doi.org/10.1016/j.scriptamat.2015.10.013

D.H. Kim, J.G. Yeo, Y.J. Choi, S.H. Lee, S.Y. An, J.Y. Kim, B.W. Lee, Magnetic properties of amorphous metallic composites with various particle sizes. J. Korean Phys. Soc. 79, 1037–1041 (2021). https://doi.org/10.1007/s40042-021-00309-6

H.J. Woo, J.H. Ahn, C.P. Kim, D.H. Choi, S. Kim, B.W. Lee, Effect of the particle size classification of FeSiCrB amorphous soft magnetic composites to improve magnetic properties of power inductors. J. Non-cryst. Solids (2021). https://doi.org/10.1016/j.jnoncrysol.2021.121309

K. Ackland, A. Masood, S. Kulkarni, P. Stamenov, Ultra-soft magnetic Co-Fe-B-Si-Nb amorphous alloys for high frequency power applications. AIP Adv. (2018). https://doi.org/10.1063/1.5007707

H.R. Lashgari, D. Chu, S. Xie, H. Sun, M. Ferry, S. Li, Composition dependence of the microstructure and soft magnetic properties of Fe-based amorphous/nanocrystalline alloys: A review study. J. Non-Crystalline Solids 391, 61–82 (2014). https://doi.org/10.1016/j.jnoncrysol.2014.03.010

H. Shokrollahi, K. Janghorban, Soft magnetic composite materials (SMCs). J. Mater. Process. Technol. 189, 1–12 (2007). https://doi.org/10.1016/j.jmatprotec.2007.02.034

R. Guo, S. Wang, Z. Yu, K. Sun, X. Jiang, G. Wu, C. Wu, Z. Lan, FeSiCr@NiZn SMCs with ultra-low core losses, high resistivity for high frequency applications. J. Alloys Compd. 830, 154736 (2020). https://doi.org/10.1016/j.jallcom.2020.154736

W. Nie, T. Yu, Z. Wang, X. Wei, High-performance core-shell-type FeSiCr@MnZn soft magnetic composites for high-frequency applications. J. Alloys Compd. 864, 158215 (2021). https://doi.org/10.1016/j.jallcom.2020.158215

H. Yu, S. Zhou, G. Zhang, B. Dong, L. Meng, Z. Li, Y. Dong, X. Cao, The phosphating effect on the properties of FeSiCr alloy powder. J. Magnetism Magn. Mater. 552, 168741 (2022). https://doi.org/10.1016/j.jmmm.2021.168741

F. Luo, X. Fan, Z. Luo, W. Hu, J. Wang, Z. Wu, G. Li, Y. Li, X. Liu, Preparation and magnetic properties of FeSiAl-based soft magnetic composites with MnO/Al2O3 insulation layer. J. Magnetism Magn. Mater. 498, 166084 (2020). https://doi.org/10.1016/j.jmmm.2019.166084

J. Wang, S. Song, H. Sun, Z. Xue, Improvement of magnetic properties for FeSi/FeSiAl compound soft magnetic composites by introducing impact of powder size matching. J. Mater. Science: Mater. Electron. 32, 8545–8556 (2021). https://doi.org/10.1007/s10854-021-05488-3

H. Li, H. Yang, Z. Li, Z. Li, X. Liu, Multifunctional FeSiAl Soft Magnetic Composites with Inorganic–Organic Hybrid Insulating Layers for High Mechanical Strength, Low Core Loss and Comprehensive Anti-Corrosion. J. Electron. Mater. (2022). https://doi.org/10.1007/s11664-022-09602-x

S. Zhu, Z. Wang, X. Kan, S. Feng, X. Liu, FeNi/Glass Soft Magnetic Composites with High Magnetic Properties. J. Supercond. Novel Magn. (2022). https://doi.org/10.1007/s10948-022-06166-z

X. Yao, P. Lu, Y. Tian, G.-Q. Lu, Y. Mei, A 200 °C curable soft magnetic composite with high permeability and low core loss for power applications at >1 MHz. J. Mag. Magnetic Mater. 535, 168061 (2021). https://doi.org/10.1016/j.jmmm.2021.168061

H.J. Woo, J.H. Ahn, C.P. Kim, D.H. Choi, S. Kim, B.W. Lee, Effect of the particle size classification of FeSiCrB amorphous soft magnetic composites to improve magnetic properties of power inductors. J. Non-Crystalline Solids 577, 121309 (2022). https://doi.org/10.1016/j.jnoncrysol.2021.121309

C. Wang, J.H. Liu, X.L. Peng, J. Li, Y.T. Yang, Y.B. Han, J.C. Xu, B. Hong, J. Gong, H.L. Ge, X.Q. Wang, FeSiCrB amorphous soft magnetic composites filled with Co2Z hexaferrites for enhanced effective permeability. Adv. Powder Technol. 33, 103378 (2022). https://doi.org/10.1016/j.apt.2021.11.030

D.H. Kim, J.-G. Yeo, Y.J. Choi, S.H. Lee, S.Y. An, J.Y. Kim, B.W. Lee, Magnetic properties of amorphous metallic composites with various particle sizes. J. Korean Phys. Soc. (2021). https://doi.org/10.1007/s40042-021-00309-6

J.G. Yeo, D.H. Kim, Y.J. Choi, B.W. Lee, Improving Power-Inductor Performance by Mixing Sub-micro Fe Powder with Amorphous Soft Magnetic Composites. J. Electron. Mater. 48, 6018–6023 (2019). https://doi.org/10.1007/s11664-019-07381-6

B.v. Velamakanni, F.F. Lange, Effect of Interparticle Potentials and Sedimentation on Particle Packing Density of Bimodal Particle Distributions During Pressure Filtration. J. Am. Ceramic Soc. 74, 166–172 (1991). https://doi.org/10.1111/j.1151-2916.1991.tb07313.x

H.Y. Sohn, C. Moreland, The effect of particle size distribution on packing density. Can. J. Chem. Eng. 46, 162–167 (1968). https://doi.org/10.1002/cjce.5450460305

R. Nowosielski, J.J. Wysłocki, I. Wnuk, P. Gramatyka, Nanocrystalline soft magnetic composite cores. J. Mater. Process. Technol. 175, 324–329 (2006). https://doi.org/10.1016/j.jmatprotec.2005.04.017

Y.J. Choi, J.H. Ahn, S.W. Kim, Y.R. Kim, B.W. Lee, Improvement in power inductor performance at 3MHz by mixing carbonyl iron powder with Fe–Si–Cr crystalline alloy. MRS Communications (2021). https://doi.org/10.1557/s43579-021-00055-7

G. Ouyang, X. Chen, Y. Liang, C. Macziewski, J. Cui, Review of Fe-6.5 wt%Si high silicon steel—A promising soft magnetic material for sub-kHz application. J. Magnetism Magn. Mater. 481, 234–250 (2019). https://doi.org/10.1016/j.jmmm.2019.02.089

N.R. Overman, X. Jiang, R.K. Kukkadapu, T. Clark, T.J. Roosendaal, G. Coffey, J.E. Shield, S.N. Mathaudhu, Physical and electrical properties of melt-spun Fe-Si (3–8 wt.%) soft magnetic ribbons. Mater. Charact. 136, 212–220 (2018). https://doi.org/10.1016/j.matchar.2017.12.019

K.I. Arai, K. Ishiyama, Recent developments of new soft magnetic materials. J. Magnetism Magn. Mater. 133, 233–237 (1994). https://doi.org/10.1016/0304-8853(94)90534-7

Y. Sato, T. Sato, Y. Okazaki, Production and properties of melt-spun Fe-6.5wt.%Si ribbons. Mater. Sci. Eng. 99, 73–76 (1988). https://doi.org/10.1016/0025-5416(88)90295-9

M.F. Littmann, Iron, S.-I. Alloys, IEEE Trans. Magnetics 7, 48–60 (1971). https://doi.org/10.1109/TMAG.1971.1066998

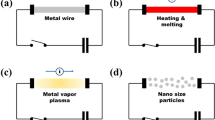

H. Suematsu, Y. Hayashi, N.D. Hieu, T.M.D. Do, T. NAKAYAMA, Preparation of iron nanosized powder by pulsed wire discharge. Jpn. J. Appl. Phys. (2021). https://doi.org/10.35848/1347-4065/ac2625

K. Weihua Jiang, Yatsui, Pulsed wire discharge for nanosize powder synthesis. IEEE Trans. Plasma Sci. 26, 1498–1501 (1998). https://doi.org/10.1109/27.736045

F. Yılmaz, D.-J. Lee, J.-W. Song, H.-S. Hong, H.-T. Son, J.-S. Yoon, S.-J. Hong, Fabrication of cobalt nano-particles by pulsed wire evaporation method in nitrogen atmosphere. Powder Technol. 235, 1047–1052 (2013). https://doi.org/10.1016/j.powtec.2012.10.024

H.M. Lee, Y.R. Uhm, C.K. Rhee, Phase control and characterization of Fe and Fe-oxide nanocrystals synthesized by pulsed wire evaporation method. J. Alloys Compd. 461, 604–607 (2008). https://doi.org/10.1016/j.jallcom.2007.07.075

Y.-W. Kim, H.S. Park, Microstructural and Magnetic Characterization of Iron Oxide Nanoparticles Fabricated by Pulsed Wire Evaporation. Electron. Mater. Lett. 15, 665–672 (2019). https://doi.org/10.1007/s13391-019-00164-5

D.H. Kim, B.W. Lee, Microstructural and magnetic characterization of fe nanosized powder synthesized by pulsed wire evaporation. J. Magnetics 22, 100–103 (2017). https://doi.org/10.4283/JMAG.2017.22.1.100

M.S. Ryłko, K.J. Hartnett, J.G. Hayes, M.G. Egan, Magnetic material selection for high power high frequency inductors in DC-DC converters, in: Conference Proceedings - IEEE Applied Power Electronics Conference and Exposition - APEC, 2009: pp. 2043–2049. https://doi.org/10.1109/APEC.2009.4802955

F. Ollendorff, M. Massekerne, Archiv Für Elektrotechnik. 25, 436–447 (1931). https://doi.org/10.1007/BF01656937

Y. Ito, H. Igarashi, M. Suzuki, Y. Iwasaki, K. Kawano, Effect of magnetic contact on macroscopic permeability of soft magnetic composite. IEEE Transac. Magnet.. 52, 1–4 (2016). https://doi.org/10.1109/TMAG.2015.2489227

A. Maruo, H. Igarashi, Analysis of Magnetic Properties of Soft Magnetic Composite Using Discrete Element Method. IEEE Trans. Magnetics 55, 1–5 (2019). https://doi.org/10.1109/TMAG.2019.2900287

M. Anhalt, B. Weidenfeller, J.L. Mattei, Inner demagnetization factor in polymer-bonded soft magnetic composites. J. Magnetism Magn. Mater. (2008). https://doi.org/10.1016/j.jmmm.2008.04.061

Y. Guo, J.G. Zhu, J. Zhong, H. Lu, J.X. Jin, Measurement and modeling of rotational core losses of soft magnetic materials used in electrical machines: A review. IEEE Trans. Magnetics 44, 279–291 (2008). https://doi.org/10.1109/TMAG.2007.911250

Y. Liu, Y. Yi, W. Shao, Y. Shao, Microstructure and magnetic properties of soft magnetic powder cores of amorphous and nanocrystalline alloys. J. Magnetism Magn. Mater. 330, 119–133 (2013). https://doi.org/10.1016/j.jmmm.2012.10.043

Acknowledgements

This research was supported by the Materials, Components & Equipments Research Program funded by the Gyeonggi Province (AICT-003-T1).

Author information

Authors and Affiliations

Contributions

MYL contributed toward methodology, preparation and writing of the original draft, and data curation. YJC contributed toward methodology, writing, reviewing, and editing of the manuscript. SHL contributed toward conceptualization, data analysis, preparation and writing of the original draft, data curation, and visualization. JHA contributed toward methodology, writing, reviewing, and editing of the manuscript. BWL contributed toward project administration, funding acquisition, and supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethical approval

We confirm that our manuscripts comply with ethical standards, and we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Research data policy

Our manuscript supports the Type 3 Research Data Policy.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, M., Choi, Y., Lee, S. et al. Controlling properties of metal–polymer soft magnetic composites through microstructural deformation for power inductor applications. J Mater Sci: Mater Electron 33, 15763–15772 (2022). https://doi.org/10.1007/s10854-022-08478-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08478-1