Abstract

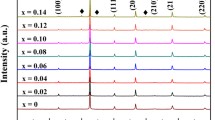

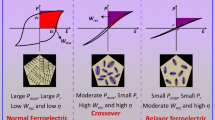

Lead-free ceramic capacitors with attractive properties such as their environmental friendliness, superior energy density, fast charge and discharge rate, and superior stability have recently received increased attention to meet liber market demands for energy storage devices in low consumption systems. However, overcoming its relatively low energy storage capacity is becoming extremely important. Based on this task, La3+ and Li+ co-doped SrTiO3 ceramics are fabricated by a solid-state reaction method. The effect of La3+ and Li+ contents on the structural, microstructure, dielectrics, and energy storage properties of SrTiO3 ceramics are systematically studied. XRD confirmed the phase structure along with Rietveld refinement studies. The morphological structure is studied using SEM. Through X-ray photoelectron spectroscopy spectra, the chemical composition and the chemical state of Sr(1−x)(Li0.50La0.50)xTiO3 (SLLTx); (0 ≤ x ≤ 8%) ceramics are studied. The energy storage properties are theoretically estimated by integrating the polarization versus electric field P-E hysteresis loop. The results show an increase in La3+ and Li+ content (x), resulting in enhanced dielectric breakdown strength, and maximum polarization yields a higher energy storage density. In the sample with x = 8%, it is found that the energy density is 2.455 J/cm3 and the energy efficiency is more than 90%. The further improvement in dielectric constant, dielectric breakdown strength, enhanced energy storage densities and the energy efficiency maintained > 90% make these materials commercially promising for energy storage device capacitors for a wide range of energy storage applications.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author on request.

References

T.H. Chung, K.W. Kwok, J. Alloys Compd. 737, 317–322 (2018)

M. Lun, W. Wang, Z. Xing, Z. Wan, W. Wu, H. Song, Y. Wang, W. Li, B. Chu, Q. He, J. Am. Ceram. Soc. 102, 5243–5252 (2019)

X. Qiao, A. Sheng, D. Wu, F. Zhang, B. Chen, P. Liang, J. Wang, X. Chao, Z. Yang, Chem. Eng. J. 408, 127368 (2021)

C. Jiang, L. Fang, M. Shen, F. Zheng, X. Wu, Appl. Phys. Lett. 94, 071110 (2009)

J. Qi, M. Cao, Y. Chen, Z. He, C. Tao, H. Hao, Z. Yao, H. Liu, J. Alloys Compd. 772, 1105–1112 (2019)

W. Pan, M. Cao, J. Qi, H. Hao, Z. Yao, Z. Yu, H. Liu, J. Alloys Compd. 784, 1303–1310 (2019)

Y.B. Wang, W.J. Jie, C. Yang, X.H. Wei, J.H. Hao, Adv. Funct. Mater. 29, 1808118 (2019)

G. Wang, Z. Lu, Y. Li, L. Li, H. Ji, A. Feteira, D. Zhou, D. Wang, S. Zhang, I.M. Reaney, Chem. Rev. 121(10), 6124–6172 (2021)

L. Yang, X. Kong, F. Li, H. Hao, Z. Cheng, H. Liu, J. Li, S. Zhang, Prog. Mater. Sci. 102, 72–108 (2019)

B. Zhong, Z. Long, C. Yang, Y. Li, X. Wei, Ceram. Int. 46(12), 20565–20569 (2020)

M. Qin, F. Gao, J. Cizek, S. Yang, X. Fan, L. Zhao, J. Xu, G. Dong, M. Reece, H. Yan, Acta Mater. 164, 76–89 (2019)

X. Guo, Y. Pu, W. Wang, L. Zhang, J. Ji, R. Shi, Y. Shi, M. Yang, J. Li, ACS Sustain. Chem. Eng. 7(15), 13041–13052 (2019)

B. Wang, Y. Pu, Y. Shi, X. Guo, L. Zhang, L. Chang, J. Li, R. Li, J. Ji, T. Wei, J. Am. Ceram. Soc. 103(12), 6811–6821 (2020)

X. Guo, Y. Pu, W. Wang, J. Ji, J. Li, M. Yang, R. Shi, Ceram. Int. 46(10), 16644–16652 (2020)

J. Liu, Q. Liu, Z. Nie, S. Nie, D. Lu, P. Zhu, Ceram. Int. 45(8), 10334–10341 (2019)

M. Qin, F. Gao, J. Cizek, S. Yang, X. Fan, L. Zhao, J. Xu, G. Dong, M. Reece, H. Yan, Scripta Mater. 190, 118–120 (2021)

A. Tkach, O. Okhay, Scr. Mater. 190, 38–39 (2021)

W. Pan, M. Cao, H. Hao, Z. Yao, Z. Yu, H. Liu, J. Eur. Ceram. 40(1), 49–55 (2020)

M.S. Alkathy, K.J. Raju, J.A. Eiras, J. Phys. D: Appl. Phys. 54(12), 125501 (2021)

A. Tkach, O. Okhay, J. Mater. Sci. Technol. 65, 151–153 (2021)

B. Zhong, C. Zuo, C. Yang, S. Yang, Y. Li, H. Yu, X. Wei, J. Alloys Compd. 901, 163556 (2022)

X. Zhu, P. Shi, R. Kang, S. Li, Z. Wang, W. Qiao, X. Zhang, L. He, Q. Liu, X. Lou, Chem. Eng. J. 420, 129808 (2021)

Y. Pu, W. Wang, X. Guo, R. Shi, M. Yang, J. Li, J. Mater. Chem. C 7, 14384–14393 (2019)

W. Pan, M. Cao, A. Jan, H. Hao, Z. Yao, H. Liu, J. Mater. Chem. C 8, 2019–2027 (2020)

X. Guo, Y. Pu, W. Wang, J. Ji, J. Li, R. Shi, M. Yang, Ceram. Int. 46, 21719–21727 (2020)

J. Zhang, K. Tse, M. Wong et al., A brief review of co-doping. Front. Phys. 11, 117405 (2016)

K.M. Batoo, R. Verma, A. Chauhan, R. Kumar, M. Hadi, O.M. Aldossary, Y. Al-Douri, J. Alloys Compd. 883, 160836 (2021)

K. Wu, H. Wang, Z. Miao, S. Ding, Y. Qi, Y. Ming, W. Ding, H. Yuan, Q. Zheng, D. Lin, Ceram. Int. 46(9), 13159–13169 (2020)

F. Zeng, M. Cao, L. Zhang, M. Liu, H. Hao, Z. Yao, H. Liu, Ceram. Int. 43(10), 7710–7716 (2017)

W. Pan, M. Cao, A. Jan, H. Hao, Z. Yao, H. Liu, J. Mater. Chem. C 8(6), 2019–2027 (2020)

C. Wang, F. Yan, H. Yang, Y. Lin, T. Wang, J. Alloys Compd. 749, 605–611 (2018)

A. Jan, H. Liu, H. Hao, Z. Yao, M. Emmanuel, W. Pan, A. Ullah, A. Manan, A. Ullah, M. Cao, A.S. Ahmad, J. Alloys Compd. 830, 154611 (2020)

T. Li, P. Chen, F. Li, C. Wang, Chem. Eng. J. 406, 127151 (2021)

L. Zheng, P. Sun, P. Zheng, W. Bai, L. Li, F. Wen, J. Zhang, N. Wang, Y. Zhang, J. Mater. Chem. C 9(15), 5234–5243 (2021)

H. Yang, J. Tian, Y. Lin, J. Ma, Chem. Eng. J. 418, 129337 (2021)

Y. Fang, M. Cao, Z. He, W. Pan, H. Wang, Z. Yao, H. Hao, H. Liu, J. Mater. Sci.: Mater. Electron. 31(16), 13408–13414 (2020)

P. Zhao, Z. Fang, X. Zhang, J. Chen, Y. Shen, X. Zhang, Q. An, C. Yang, X. Gao, S. Zhang, B. Tang, ACS Appl. Mater. Interface 13, 24833–24855 (2021)

L. Cao, Y. Yuan, E. Li, S. Zhang, Ceram. Int. 45(5), 5660–5667 (2019)

Z. Yang, Y. Yuan, L. Cao, E. Li, S. Zhang, Ceram. Int. 46(8), 11282–11289 (2020)

X. Kong, L. Yang, Z. Cheng, S. Zhang, J. Am. Ceram. Soc. 103(3), 1722–1731 (2020)

L.L. Liu, B.K. Chu, P. Li, P. Fu, J. Du, J.G. Hao, W. Li, H.R. Zeng, Chem. Eng. J. 429, 132548 (2022)

M.V. Le et al., Catalysts 11(5), 564 (2021)

R.D. Shannon, Acta Cryst. A 32, 751–767 (1976)

U. Holzwarth, N. Gibson, Nat. Nanotechnol. 6, 534–534 (2011)

V.D. Mote, Y. Purushotham, B.N.J. Dole, Theor. Appl. Phys. 6(1), 1–8 (2012)

M.S. Alkathy, K.K. Bokinala, K. James Raju, C. J. Mater. Sci.: Mater. Electron. 27(4), 3175–3181 (2016)

M.S. Alkathy, K.C.J. Raju, Mater. Sci.: Mater. Electron. 27(9), 8957–8965 (2016)

K. Madhan, R. Murugaraj, Appl. Phys. A 126(2), 1–12 (2020)

A.K. Yadav, H. Fan, B. Yan et al., J. Mater. Sci. Mater. Electron. 32, 23103–23115 (2021)

A.K. Yadav, A. Verma, S. Kumar, V. Srihari, A.K. Sinha, V.R. Reddy, S.W. Liu, S. Biring, S. Sen, J. Appl. Phys. 123, 2124102 (2018)

R.C. Hatch, K.D. Fredrickson, M. Choi, C. Lin, H. Seo, A.B. Posadas, A.A. Demkov, J. Appl. Phys. 114(10), 103710 (2013)

B. Erdem, R.A. Hunsicker, G.W. Simmons, E.D. Sudol, V.L. Dimonie, M.S. El-Aasser, Langmuir 17(9), 2664–2669 (2001)

L. Li, T. Lu, N. Zhang, J. Li, Z.J. Cai, Mater. Chem. C 6(9), 2283–2294 (2018)

M.S. Alkathy, F.L. Zabotto, K.J. Raju, J.A. Eiras, Mater. Chem. Phys. 275, 125235 (2022)

M.S. Alkathy, F.L. Zabotto, F.P. Milton, J.A. Eiras, J. Alloys Compd. 908, 164222 (2022)

Y. Lee, C.H. Lee, T. Nam, S. Lee, I.K. Oh, J.Y. Yang, D.W. Choi, C. Yoo et al., J. Mater. Sci. 54(16), 11145–11156 (2019)

N. Hornsveld, B. Put, W.M. Kessels, P.M. Vereecken, M. Creatore, Plasma-assisted and thermal atomic layer deposition of electrochemically active Li2CO3. RSC Adv. 7(66), 41359–41368 (2017)

M. Ganguly, S.K. Rout, T.P. Sinha, S.K. Sharma, H.Y. Park, C.W. Ahn, I.W. Kim, J. Alloys Compd. 579, 473 (2013)

M. Rizwan, I. Zeba, M. Shakil, S.S. Gillani, Z. Usman, Optik 211, 164611 (2020)

A.J. Moulson, J.M. Herbert, Electroceramics: Materials, Properties and Applications (Chapman and Hall, London, 1990), p. 24

S.K. Ghosh, M. Ganguly, S.K. Rout, T.P. Sinha, Eur. Phys. J. Plus 130(4), 1–18 (2015)

M. Soni, M. Saleem, N. Bajpai, S. Chouhan, M.D. Varshney, A. Mishra, AIP Conf. Proc. 2100, 020185 (2019)

M.S. Alkathy, J.A. Eiras, K.J. Raju, Ferroelectrics 570(1), 153–161 (2021)

Z. Liang, M. Liu, C. Ma, L. Shen, L. Lu, C.L. Jia, J. Mater. Chem. A 6(26), 12291–12297 (2018)

X. Jiang, D. Wang, M. Sun, N. Zheng, S. Jia, H. Liu, D. Zhang, W. Li, RSC Adv. 7(79), 49962–49968 (2017)

A. Kumar, S.H. Kim, M. Peddigari et al., Electron. Mater. Lett. 15, 323–330 (2019)

N. Qu, H. Du, X. Hao, J. Mater. Chem. C 7(26), 7993–8002 (2019)

A. Kumar, J.Y. Yoon, A. Thakre, M. Peddigari, D.Y. Jeong, Y.M. Kong, J. Ryu, J. Korean Ceram. Soc. 56(4), 412–420 (2019)

Z. Yao, Q. Luo, G. Zhang, H. Hao, M. Cao, H.J. Liu, Mater. Sci.: Mater. Electron. 28(15), 11491–11499 (2017)

A. Kumar, G. Lee, Y.G. Chae, A. Thakre, H.S. Choi, G.H. Nam, J. Ryu, Ceram. Int. 47(22), 31590–31596 (2021)

A. Kumar, S.H. Kim, A. Thakre, G. Lee, Y.G. Chae, J. Ryu, J. Therm. Spray Technol. 30(3), 591–602 (2021)

Acknowledgements

The authors would like to acknowledge the experimental facilities provided by CNPq and FAPESP in Grupo de Materiais Ferroicos (GMF), Physics Department/ UFSCar. For financial support, Dr Alkathy is greatly indebted to the Sao Paulo Research Foundation (FAPESP: Grant no# 2019/03110-8) and (FAPESP: Grant no# 2017/13769-1).

Author information

Authors and Affiliations

Contributions

All authors have contributed in preparation of the manuscript. MSA: Synthesis, Analysis and interpretation of the data, calculations, visualization, conceptualization, methodology, and writing-original draft. FLZ and FPM: Conceptualization, methodology, suggestions, and spectroscopic characterizations, and Prof JAE: supervision, writing, and approval of the final version.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Research involving human and animal rights

This article does not contain any studies involving animal or human participants performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alkathy, M.S., Zabotto, F.L., Milton, F.P. et al. Achieving high energy storage performance and breakdown strength in modified strontium titanate ceramics. J Mater Sci: Mater Electron 33, 15483–15494 (2022). https://doi.org/10.1007/s10854-022-08455-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08455-8