Abstract

Various chalcogenide amorphous films of Te81Ge15Bi4 in the range (143–721 nm) were synthesized using the thermal evaporation technique. The ac electrical conductivity \({\sigma }_{ac}\left(\omega \right)\) and dielectric measurements were examined for the studied films over the temperature and frequency ranges of (303–393 K) and (100 Hz–1 MHz), respectively. The obtained results of ac conductivity \({\sigma }_{ac}\left(\omega \right)\) are temperature dependent and follow the relation \({\sigma }_{ac}\left(\omega \right)\propto {\omega }^{s}\), where the frequency exponent \(s\) decrements with temperature through the examined range. These results of \({\sigma }_{ac}\left(\omega \right)\) and \(s\) are explained based on the correlated barrier hopping CBH model. Values of ac activation energy \(\Delta {E}_{\sigma }\left(\omega \right)\) show thickness independence and decrease from 0.270 to 0.144 eV as the frequency increases. The estimated maximum barrier height \({W}_{M}\) values decrement with temperature in the considered frequency range. The density of localized states near the Fermi level \(N\left({E}_{F}\right)\) increases with increasing temperature and frequency. The dielectric constant \({\varepsilon }_{1}(\omega )\) and loss \({\varepsilon }_{2}(\omega )\) were found to increment with temperature and decrement with frequency. The obtained results indicate that \({\sigma }_{ac}\left(\omega \right)\), \(N\left({E}_{F}\right)\), \({\varepsilon }_{1}\left(\omega \right)\) and \({\varepsilon }_{2}\left(\omega \right)\) are enhanced by decreasing the thickness of the film sample in the investigated ranges of temperature and frequency. The real \({M}_{1}(\omega )\) and imaginary \({M}_{2}(\omega )\) parts of the electric modulus were studied for the films under test, and the value of the activation energy for relaxation \(\Delta {E}_{r}\) (0.143 ± 0.002 eV) is thickness independent in the investigated range.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The physical characteristics of amorphous semiconductors have received a lot of attention in recent years. Many attempts have been made to obtain a stable amorphous material. Chalcogenide glasses (ChGs) represent an important class of these amorphous materials. The extension of the glass formation domain in the ChGs gives rise to the production of stable glasses with improved physical properties that have been utilized in the fabrication of various solid-state devices. The presence of short-range order (SRO) as well as localized states (LS) and defects in the band gap has been identified as characteristics of these glasses [1, 2]. Furthermore, they are employed as fundamental materials in a wide range of applications, including phase change memories (PCM), optical amplifiers, infrared transmission windows, optical fibers, and all types of optical switches [3,4,5,6,7,8]. The use of ChG thin films demands knowledge of their physical properties, mainly optical, electrical, and other properties. The characteristics of such ChG compositions are equivalent to those of numerous types of recent polymer nanocomposites and could be applied in different fields [9,10,11,12,13,14].

Compared to sulfides and selenides, tellurides have greater crystallizability. This improves the transition from amorphous to crystalline phases in Te-based glasses, making them more suitable materials for (PCM) applications. GeTe-based glasses, in particular, have been extensively researched for their potential use in PCM [15,16,17]. Bi-Te glasses and their derivatives exhibit remarkable charge transfer, indicating their prospective thermoelectric and non-linear optical properties, as well as various applications such as optical data recording, IR spectroscopy and detectors, laser diodes, sensors, and so on [18,19,20]. The Ge-Te-X (X = Bi, As, Sb, Bi, In, etc.) ChGs have gotten a lot of interest in recent years because of their prospective applications, and a great deal of research has been done on the bulk and thin films of these ChGs [15, 21,22,23,24,25,26,27].

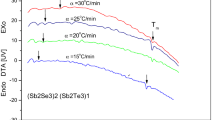

Chandasree et al. [15] studied the electrical switching and thermal properties of Ge18Te82-xBix (1 ≤ x ≤ 4) glasses and found that, Ge18Te82-xBix films exhibited electrical switching behavior of the memory type and a linear variation of switching voltage \({V}_{th}\) with increased film thickness. In addition, \({V}_{th}\) decreased with increasing temperature and Bi content as a result of the decrement in the crystallization activation energy. Sharma and Barman [21, 22, 28] studied the transport and physical properties of amorphous Ge20Te80-xBix (x = 0, 1.5, 2.5, 5.0) glassy alloys and reported that the glass transition temperature \({T}_{g}\) and crystallization temperature \({T}_{c}\) increase as the Bi content increases. The dc conductivity \({\sigma }_{dc}\), the activation energy \(\Delta {E}_{\sigma }\), the optical energy band gap \({E}_{g}^{opt}\) and cohesive energy (CE) decrease with increasing Bi content. Atyia et al. [29] investigated the effects of temperature and frequency on the ac electrical conductivity \({\sigma }_{ac}(\omega )\) and dielectric characteristics of amorphous Ge15Se60Bi25 films and concluded that the ac conductivity \({\sigma }_{ac}(\omega )\) and the density of states \(N({E}_{F})\) increment with temperature and frequency, while hopping is the predominant mechanism for conduction. The dielectric constant \({\varepsilon }_{1}(\omega )\) and the loss \({\varepsilon }_{2}(\omega )\) increase with temperature and decrease with frequency. Atyia [30] studied the dielectric relaxation and ac conductivity of bulk Se70Bi(30−x)Tex (x = 0, 15) ChGs and concluded that, \({\varepsilon }_{1}(\omega )\) and \({\varepsilon }_{2}(\omega )\) decrease with increasing frequency and temperature. The Cole–Cole diagram is used to evaluate the molecular relaxation time \(\tau\), relaxation activation energy \({\Delta E}_{\tau }\) and distribution parameter for Se70Bi(30−x)Tex (x = 0, 15) ChGs. The correlated barrier hopping (CBH) model is used to interpret the change in ac conductivity \({\sigma }_{ac}(\omega )\) and frequency exponent \(s\) with temperature, and the activation energy \(\Delta {E}_{\sigma }\left(\omega \right)\) decreases with frequency. The presence of Te atoms enhances the density of localized states \(N({E}_{F})\) in the band tails, resulting in an increase in \({\sigma }_{ac}(\omega )\). Hegab et al. [31] examined the ac electrical conductivity \({\sigma }_{ac}(\omega )\) and dielectric characteristics of amorphous Se80Te20−xGex (x = 5, 7 and 10 at.%) ChG films and found that, \({\sigma }_{ac}(\omega )\) increments with temperature, frequency and the addition of Ge, which is explained based on the CBH model. The density of localized states \(N({E}_{F})\) decreases and the maximum barrier height \({W}_{M}\) increases with Ge addition. Both \({\varepsilon }_{1}\left(\omega \right)\) and \({\varepsilon }_{2}\left(\omega \right)\) increase with temperature and decrease with frequency and Ge addition. Bhatnagar and Bhatia [32] studied the reliance of \({\sigma }_{ac}(\omega )\) on frequency and temperature for bulk Ge20S80-xBix (x = 0, 4, 11, 15) amorphous semiconductors and concluded that, \({\sigma }_{ac}(\omega )\) is independent of temperature and increases linearly with frequency for Ge20S80. Also, \({\sigma }_{ac}(\omega )\) increases with the addition of Bi, particularly at low frequencies and high temperatures. The temperature dependence of \({\sigma }_{ac}(\omega )\) and \(s\) is interpreted by the CBH model for Ge20S80-xBix (x = 0, 4, 11, 15).

Measurement of ac electrical conductivity \({\sigma }_{ac}(\omega )\) provides a basic technique for investigating the nature of localized states (LS) and explaining defect centers in ChGs, as well as the behavior of the conduction mechanism [33, 34]. Quantum mechanical tunnelling (QMT) [2, 35], overlapping large polaron tunnelling (OLPT) [36], non-overlapping small polaron tunnelling (NSPT) [37], and correlated barrier hopping (CBH) [34, 38] are some of the models that have been proposed to examine the conduction process in ChGs. In chalcogenide glassy semiconductors, the CBH model has been widely employed. In this model, \({\sigma }_{ac}\left(\omega \right)\propto {\omega }^{s}\), where \(\omega\) is the angular frequency and the frequency exponent (\(s\le 1\)) is substantially temperature dependent [39]. The study of dielectric characteristics, including \({\varepsilon }_{1}(\omega )\) and \({\varepsilon }_{2}(\omega )\) of ChGs across a wide range of temperatures and frequencies, aids in determining their insulating capabilities and may also enable us to understand the structure of these glasses to some extent.

The composition Te81Ge15Bi4 offers a wide range of physical characteristics and is interesting in optoelectronic devices [40], and it has demonstrated a high ability to be used as a memory switch in switching applications [41]. The previous analysis of linear and non-linear optical properties as well as the switching phenomenon of Te81Ge15Bi4 thin films provides new optical parameters data to be used in many optoelectronic applications such as, optical recorders, optical fibers, solar cells, photonic circuits, photolithography, reversible phase change, switching and memory devices. The present work aims to study the temperature, frequency and thickness dependence of ac conductivity \({\sigma }_{ac}\left(\omega \right)\), dielectric constant \({\varepsilon }_{1}(\omega )\), dielectric loss \({\varepsilon }_{2}(\omega )\) and dielectric modulus (\({M}_{1}\left(\omega \right)\) and \({M}_{2}\left(\omega \right)\)) to investigate the conduction process and dielectric properties of Te81Ge15Bi4 chalcogenide glass films.

2 Experimental procedures

A chalcogenide glass with the nominal composition of Te81Ge15Bi4 was synthesized in 5 gm weight by melting the appropriate percentages of the constituent elements (high purity 99.999%, from Aldrich (Co, UK)) in a sealed dry-cleaned silica ampoule (at 10–5 Torr) of length 0.20 m and diameter 0.016 m in an oscillatory furnace built especially for this purpose. The details of synthesis have been mentioned in previous work [40, 41]. Since the constituent elements of the investigated composition differ in melting points; the synthesis process was accomplished in steps. At the end of each step, the temperature was kept constant for a certain duration to decrease the vapor pressure of the melted elements via their reaction with other elements in the composition. The temperature was raised very slowly, at a rate of ~ 60 K/h. The temperature was initially to 545 K (m.p. of Bi) and held constant for 2 h, then to 723 K (m.p. of Te) and held constant for 2 h, then to 1212 K (m.p. of Ge). Finally, it was elevated to 1273 K and held at that temperature for 24 h. The homogeneity of the examined composition is ensured by the extended duration of the synthesis and the mechanical shaking of the melt during the furnace oscillation. An ampoule containing the molten materials was rapidly quenched in icy water to obtain an amorphous specimen.

Thin films of different thicknesses in the range (143–721 nm) were deposited under a vacuum of (10–5 Torr) using the thermal evaporation method onto highly cleaned and dry glass substrates pre-provided with Al film as the lower electrode using a coated unit (Edward 306 A). The deposition rate (4 nm/s) and the sample film thickness were both controlled using a quartz crystal monitor (Edwards DTM5). A molybdenum boat was monitored to bring the chalcogenide material above the melting point to establish a vapor pressure in the vacuum chamber and was kept at a constant evaporation rate. All the films were obtained under the same conditions. Then the film samples were covered by another Al film that acted as an upper electrode, i.e., the film sample was sandwiched between two Al electrodes to measure ac electrical conductivity \({\sigma }_{ac}\left(\omega \right)\) and other dielectric parameters. The film thickness was estimated by Tolonsky’s interferometric method [42].

The amorphous nature and the chemical composition of the obtained films were checked previously using X-ray diffraction (XRD) via the Philips X-ray unit (PW 710) and energy dispersive X-ray (EDX) analyses via (JEOL 5400 SEM), respectively [41]. For ac measurements, a programable automatic RLC meter (FLUKE PM 6306) was utilized to directly measure the capacitance (\(C\)), the impedance (\(Z\)) and the loss tangent \(\left({\text{tan}}\delta \right)\). The scanning frequency ranged from 100 Hz to 1 MHz through the temperature range from 303 to 393 K, which is below the glass transition temperature \({T}_{g}\) (408 K) of the studied composition [41].

The total electrical conductivity was calculated from the relation \({\sigma }_{tot}\left(\omega \right)=d/Za\), where \(d\) is the film thickness and \(a\) is the cross-section area. The dielectric constant was determined using the equation \({\varepsilon }_{1}\left(\omega \right)=Cd/a{\varepsilon }_{0}\), where \({\varepsilon }_{0}\) is the permittivity of free space. Finally, the calculation of the dielectric loss was obtained from \({\varepsilon }_{2}\left(\omega \right)={\varepsilon }_{1}tan\delta\), where \((\delta =90-\varphi )\), \(\varphi\) is the phase angle [17, 36].

3 Results and discussion

3.1 Temperature and frequency dependence of the ac electrical conductivity

Great information about the defect levels that lie in the gap of semiconductor materials will be obtained by studying the ac electrical conductivity \({\sigma }_{ac}\left(\omega \right)\) properties of these materials. The ac electrical conductivity \({\sigma }_{ac}\left(\omega \right)\) for Te81Ge15Bi4 film samples of various thicknesses in the range of (143–721 nm) was measured as a function of temperature and frequency in the ranges of (303–393 K) and (100 Hz–1 MHz), respectively. The ac electrical conductivity \({\sigma }_{ac}\left(\omega \right)\) was calculated using the following relation [17, 36]:

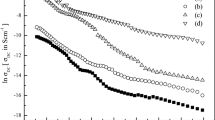

where \({\sigma }_{dc}\) is the dc electrical conductivity, which is much smaller than the total electrical conductivity \({\sigma }_{tot}\left(\omega \right)\), so \({\sigma }_{dc}\) can be neglected in Eq. (1) and the measured values of \({\sigma }_{tot}\left(\omega \right)\) are considered the typical values of \({\sigma }_{ac}\left(\omega \right)\) for the investigated film samples. The temperature dependence of \({\sigma }_{ac}\left(\omega \right)\) was studied for Te81Ge15Bi4 films in the considered ranges of temperature and frequency. The obtained results are illustrated as \(ln{\sigma }_{ac}(\omega )\) versus \(1000/T\) at various frequencies for the studied films with thicknesses of 143 nm and 721 nm, as presentative examples in Fig. 1a, b. It is observed that, \({\sigma }_{ac}(\omega )\) increases linearly with temperature for all investigated films in the studied range. The increase of \({\sigma }_{ac}(\omega )\) with temperature may be due to the impurities existing below the bottom of the conduction band (CB), resulting in a low activation energy [43, 44]. The movement of charge carriers in the investigated composition causes the increase in \({\sigma }_{ac}(\omega )\) due to the thermally induced hopping process between two places separated by an energy barrier inside localized states, which clarifies the transportation mechanism. This indicates that ac conductivity \({\sigma }_{ac}(\omega )\) is activated thermally from the LS in the band gap or its tails [1, 45].

Values of ac conduction activation energy \(\Delta {E}_{\sigma }\left(\omega \right)\) were calculated at various frequencies for all the examined films from the slopes of the obtained linear lines of the relation between \(ln{\sigma }_{ac}\left(\omega \right)\) versus \(1000/T\) using the relation [45, 46]:

where \({\sigma }_{o}(\omega )\) is a constant and \({k}_{B}\) is Boltzmann’s constant. The frequency reliance of the average values of \(\Delta {E}_{\sigma }\left(\omega \right)\) for all the investigated film samples of different thicknesses is shown in Fig. 2. Values of \(\Delta {E}_{\sigma }\left(\omega \right)\) at each frequency for samples lie on average within 5% of experimental error. According to that, \(\Delta {E}_{\sigma }(\omega )\) is thickness independent in the studied range. It is observed from Fig. 2 that, \(\Delta {E}_{\sigma }\left(\omega \right)\) reduces as the frequency increases. This reduction may be due to the increase in the frequency of the applied field, which increases the electronic jumps (hops) between the LS. As a result, \(\Delta {E}_{\sigma }(\omega )\) reduces, as found in other amorphous materials [8, 17, 31, 45,46,47]. In addition, the values of \(\Delta {E}_{\sigma }\left(\omega \right)\) obtained at any frequency are less than the previously obtained dc activation energy \(\Delta {E}_{\sigma }\)(0.32 eV) in the same temperature range [41]. The discrepancy between the dc activation energy \(\Delta {E}_{\sigma }\) and \(\Delta {E}_{\sigma }(\omega )\) can be explained by charge carriers in dc conduction choosing the simplest paths with some substantial jumps, but it is not as significant in ac conduction [8, 17, 31, 45,46,47,48]. The smaller \(\Delta {E}_{\sigma }\left(\omega \right)\) values and the enhancement of \({\sigma }_{ac}(\omega )\) with increasing frequency emphasize that the mechanism of hopping conduction is the predominant mechanism in the investigated composition [8, 17, 31, 45,46,47,48].

The ac conductivity \({\sigma }_{ac}\left(\omega \right)\) changed with frequency according to [49, 50]:

where \(A\) is a constant that depends on temperature, \(s\) is the frequency exponent and \(\omega\) is the angular frequency. The dependence of \({\sigma }_{ac}\left(\omega \right)\) on frequency is represented as \(ln{\sigma }_{ac}(\omega )\) against \(ln\omega\) at various temperatures for Te81Ge15Bi4 films of thicknesses of 335 nm and 508 nm in Fig. 3a, b, as representative examples. As observed from this figure, each obtained relation consists of two straight lines in both the lower (100 Hz–100 kHz) and higher (100 kHz–1 MHz) frequency ranges (I) and (II), respectively. In both ranges (I) and (II), \({\sigma }_{ac}\left(\omega \right)\) increases linearly with frequency based on Eq. (3). The values of \(s\) were obtained from the slopes of the linear lines in the two frequency ranges (I&II) for the investigated films of various thicknesses. Figure 4a, b shows the dependency of the average values of the frequency exponent \(\overline{s }\) on temperature in the frequency ranges (I) and (II) for Te81Ge15Bi4 films of various thicknesses, respectively. It is obvious that,\(\overline{s }\) decreases with temperature in the examined ranges of frequency.

In the quantum mechanical tunnelling (QMT) model [2, 35], \(s\) is independent of the temperature and has a value of ≈ 0.81. Thus, the (QMT) model is inapplicable to our study of the frequency dependence of \({\sigma }_{ac}\left(\omega \right)\). The reliance of \({\sigma }_{ac}\left(\omega \right)\) on frequency in the ChGs can be explained by the correlated barrier hopping (CBH) model [34, 38]. According to this model, \(s\) decrements with temperature and is given as [34, 38]:

where \({W}_{M}\) is the maximum barrier height and \(\tau\) is the distinctive relaxation time around the atomic vibration period (\(\tau ={10}^{-12} sec\)) [50, 51]. Therefore, the obtained results of the frequency dependence of \({\sigma }_{ac}\left(\omega \right)\) and the temperature dependence of \(\overline{s }\) for the studied film samples can be explained based on the (CBH) model. From Eq. (4), \(s\) tends to unity for large values of (\({W}_{M}/{k}_{B}T\)) and this equation is reduced to [50, 51]:

Values of \({W}_{M}\) can be evaluated from the obtained average values of \(\overline{s }\) for Te81Ge15Bi4 films at different temperatures in both frequency ranges (I) and (II) using Eq. (5). The variation of \({W}_{M}\) with temperature in both frequency ranges (I) and (II) is shown in Fig. 5a, b. It is observed that, \({W}_{M}\) decrements with temperature in both frequency ranges for Te81Ge15Bi4 films. The reduction in \({W}_{M}\) can be interpreted by the pike model [51] in which potential wells are overlapped for neighboring sites, reducing the effective height of the barrier from \({W}_{M}\) to \({W}_{H}\). The condition \({W}_{H}/{W}_{M}<0.5\) is satisfied. The value of \({W}_{H}\approx {W}_{M}/4\) in the case of strong overlapping among the potential wells. Thus, the reduction of \({W}_{M}\) with temperature can be attributed to the increase of overlapping degrees among potential wells of the sites in the structure of the investigated samples, which also explains the increase in \({\sigma }_{ac}\left(\omega \right)\) with increasing temperature [51, 52].

The ac conductivity \({\sigma }_{ac}\left(\omega \right)\) is associated with the density of LS near the Fermi level \(N({E}_{F} )\) according to the equation [49]:

where \(e\) is the charge of an electron, \(\alpha\) is the exponential decay parameter of the LS wave function and \({\nu }_{ph}\) is the phonon frequency, where \({\alpha }^{-1}=10\mathrm{ \AA }\) and \({\nu }_{ph}={10}^{12} Hz\) [49]. The calculated values of \(N({E}_{F} )\) at different temperatures and frequencies at 10 kHz and 303 K, respectively, for Te81Ge15Bi4 films are registered in Table 1. It is obvious that, \(N({E}_{F} )\) increments with temperature and frequency, which has the same behavior as ac electrical conductivity\({\sigma }_{ac}(\omega )\). This is due to the reduction in the intermediate band as the temperature and frequency increase [44]. As a result, \({\sigma }_{ac}(\omega )\) enhances as the density of LS (\(N({E}_{F})\)) increments in the structure of the examined film samples [17, 29, 45, 47, 53]. The same behavior of \(N({E}_{F})\) at various temperatures and frequencies was obtained for all the investigated films.

3.2 Dielectric properties

3.2.1 Temperature and frequency dependence of the dielectric constant

The temperature and frequency dependence of \({\varepsilon }_{1}\left(\omega \right)\) were studied for Te81Ge15Bi4 films of various thicknesses in the above-mentioned considered ranges of temperature and frequency. Figure 6a, b depicts the frequency dependence of \({\varepsilon }_{1}(\omega )\) at different temperatures for Te81Ge15Bi4 films with thicknesses of 335 nm and 721 nm, respectively. It is obvious that, \({\varepsilon }_{1}(\omega )\) increments with temperature but decrements with frequency. Moreover, the increase in \({\varepsilon }_{1}(\omega )\) at low frequencies is more pronounced.

The increment of \({\varepsilon }_{1}(\omega )\) with temperature can be interpreted by the fact that dipoles in polar materials do not change orientation at low temperatures, but as temperature rises, the orientation of dipoles will become more freely as well as the orientational polarization increase, resulting in \({\varepsilon }_{1}(\omega )\) increasing as proposed by Srivastava et al. [54]. The increment of \({\varepsilon }_{1}(\omega )\) with frequency can be attributed to the involvement of ionic, electronic, orientational and space charge polarization in the dielectric constant \({\varepsilon }_{1}(\omega )\) of polar materials at low frequencies [34, 55]. As the frequency of the field increases, dipoles become unable to rotate quickly enough, and their oscillations begin to lag behind it. At high frequencies, dipoles were unable to follow the variations of the field, so the orientation polarization was reduced and, as a result, the space charge polarization caused \({\varepsilon }_{1}(\omega )\) decrease to a fixed value [34, 55].

3.2.2 Temperature and frequency dependence of the dielectric loss

Figure 7a, b depicts the frequency dependence of \({\varepsilon }_{2}\left(\omega \right)\) for Te81Ge15Bi4 films with thicknesses of 143 nm and 508 nm, respectively, at various temperatures. It is noticed that, \({\varepsilon }_{2}(\omega )\) reduces with frequency but enhances with temperature. The variation of \({\varepsilon }_{2}(\omega )\) with frequency is small in the high frequency range, but obviously increases in the low frequency range.

As suggested by Stevels [56], the source of dielectric loss is vibrational, dipole and conduction losses. These conductive losses are caused by ion migration over long distances, i.e., ions hop over the lowest potential barriers. In this procedure, ions share some of their own energy in the form of heat energy with the network, and this loss of energy per cycle is proportional to \({\sigma }_{ac}(\omega )\) as [8, 53, 57]:

The dielectric loss \({\varepsilon }_{2}\left(\omega \right)\) has the smallest value at lower temperatures, while the conduction loss increases as a result of the increase of \({\sigma }_{ac}(\omega )\) at higher temperatures. The decrement of \({\varepsilon }_{2}(\omega )\) with frequency may be explained as follows: at low frequencies, the high values of \({\varepsilon }_{2}(\omega )\) are caused by ions migrating through the material. Due to ion jumping, conduction and ion polarization losses, \({\varepsilon }_{2}(\omega )\) decreases when frequency is increased. The oscillation of ions, at higher frequencies, will be a source of dielectric loss [56].

3.3 Effect of thickness

The dependence of \({\sigma }_{ac}\left(\omega \right)\), \({\varepsilon }_{1}\left(\omega \right)\) and \({\varepsilon }_{2}\left(\omega \right)\) on film thickness was studied for Te81Ge15Bi4 films at various temperatures and frequencies at 10 kHz and 303 K, respectively, as presented in Figs. 8a-c and 9a-c as representative examples. At different temperatures and frequencies, all the examined films exhibited the same behavior. It is noticed from Figs. 8 and 9 that, \({\sigma }_{ac}\left(\omega \right)\), \({\varepsilon }_{1}\left(\omega \right)\) and \({\varepsilon }_{2}\left(\omega \right)\) decreased with increasing the thickness of the film in the investigated ranges of temperature and frequency. The decrease in \({\sigma }_{ac}\left(\omega \right)\), \({\varepsilon }_{1}\left(\omega \right)\) and \({\varepsilon }_{2}(\omega )\) with increasing the thickness of the film can be interpreted by the existence of a homogeneous network in thicker films, as a result of which the number of defects and LS are reduced in the investigated samples [45, 58,59,60,61]. Also, \(N\left({E}_{F} \right)\) increases with the decrease of film thickness (see Table 1), which leads to the increase of \({\sigma }_{ac}\left(\omega \right)\) with the decrease of film thickness at different temperatures and frequencies. Moreover, the decrease of \({\varepsilon }_{2}\left(\omega \right)\) with increasing film thickness can be confirmed using Eq. (7), which implies that \({\varepsilon }_{2}\left(\omega \right)\) increases with increasing \({\sigma }_{ac}\left(\omega \right)\). Since \({\sigma }_{ac}\left(\omega \right)\) increases with the decrease of film thickness, so \({\varepsilon }_{2}(\omega )\) also increases [17, 45, 48].

3.4 Electric modulus

When the electrical displacement in the materials remains constant, the electrical modulus relates to the electric field relaxation. The complex dielectric modulus \({M}^{*}(\omega )\), which is the reciprocal of the complex permittivity [\({\varepsilon }^{*}\left(\omega \right)={\varepsilon }_{1}\left(\omega \right)- i {\varepsilon }_{2}(\omega )\)], is specified by [48, 62]:

where \({M}_{1}\left(\omega \right)\) and \({M}_{2}\left(\omega \right)\) are the real and imaginary components of electrical modulus, respectively, and are defined as [48, 62]:

Figures 10a, b and 11a, b show the frequency dependence of \({M}_{1}\left(\omega \right)\) and \({M}_{2}\left(\omega \right)\) for Te81Ge15Bi4 at different temperatures of thickness of 143 nm and 508 nm, respectively. It is observed from Fig. 10a, b that, \({M}_{1}\left(\omega \right)\) decreases with temperature and increases with frequency to a maximum at a constant value as a result of the relaxation process. At lower frequencies,\({M}_{1}\left(\omega \right)\) approaches to zero suggesting that the polarization of the electrode is eliminated [48, 63, 64].

Figure 11a, b demonstrates a single relaxation peak at a specific frequency \({\omega }_{max}\) named the relaxation frequency, which shifts to greater frequencies with increased temperature, indicating the relaxation frequency \({\omega }_{max}\) is thermally activated nature. At lower frequencies, the increment in \({M}_{2}\left(\omega \right)\) indicates that the charge carriers are successfully hopping from one site to the other adjacent sites. While at higher frequencies, the reduction in \({M}_{2}\left(\omega \right)\) suggests that the charge carriers are spatially constrained to their potential wells and can thus undergo localized movement within the localized sites only a short range [44, 48, 63, 64]. The frequency region below the maximum peak of \({M}_{2}\left(\omega \right)\) indicates that the charge carriers are mobile over long distances and above the maximum peak, the carriers are restricted to potential mobile wells over short distances [44, 48, 63, 64].

The temperature dependence of the average values of \({\omega }_{max}\) for Te81Ge15Bi4 films of various thicknesses is presented in Fig. 12, which is satisfied by the equation [48, 62]:

where \(\Delta {E}_{r}\) is the activation energy for the relaxation process or the hopping activation energy of charge carries and \({\omega }_{o}\) is the relaxation frequency at infinite temperature. Values of \(\Delta {E}_{r}\) and \({\omega }_{o}\) were estimated from the slope and intercept of the linear lines in Fig. 12 and recorded in Table 2. Moreover, values of the characteristic relaxation time \({\tau }_{o}\), which is equal to the inverse of the frequency of the maximum peak position [\({\tau }_{o}=({\omega }_{o}{)}^{-1}\)] were calculated for the studied film samples and presented in the same table. It is observed from this table that, \({\Delta E}_{r}\) is thickness independent for Te81Ge15Bi4 films in the investigated range. Also, the values of \({\omega }_{o}\) decreased and \({\tau }_{o}\) increased with increasing film thickness, which may be due to the decrease in the dielectric loss (dissipated thermal energy) with increasing film thicknesses, as seen in Figs. 8c and 9c [48, 62,63,64].

4 Conclusions

From the obtained results of ac conductivity \({\sigma }_{ac}(\omega )\) measurements, it is concluded that the temperature and frequency dependence of \({\sigma }_{ac}(\omega )\) for Te81Ge15Bi4 films has been found to support the CBH model since the frequency exponent \(s\) is predicted to have a temperature dependence, decreasing with increasing temperature through the investigated ranges of temperature (303–393 K) and frequency (100 Hz–1 MHz). The ac electrical conductivity \({\sigma }_{ac}(\omega )\) is activated thermally from LS in the band gap or its tails. The ac activation energy \(\Delta {E}_{\sigma }\left(\omega \right)\) values show thickness independence and reduce from 0.270 to 0.144 eV as the frequency increases. The evaluated maximum height of barrier \({W}_{M}\) values decreased with temperature through the entire range of frequency. The density of LS near the Fermi level \(N\left({E}_{F}\right)\) increases with increasing temperature and frequency. The dielectric constant \({\varepsilon }_{1}(\omega )\) for the studied films shows an increment with temperature and a decrement with frequency. This behavior of \({\varepsilon }_{1}(\omega )\) can be attributed to the variation of the different types of polarization with temperature and frequency. Also, the analysis of the dielectric loss \({\varepsilon }_{2}(\omega )\) results shows that it increments with temperature and decrements with frequency, which was interpreted as the change of different losses of the relaxation phenomenon with temperature and frequency. The obtained results show that as film thickness increased, \({\sigma }_{ac}\left(\omega \right)\), \({\varepsilon }_{1}\left(\omega \right)\) and \({\varepsilon }_{2}\left(\omega \right)\) decreased due to the presence of a homogenous network in thicker films, reducing the defect numbers and LS in the investigated films. In addition, \(N\left({E}_{F} \right)\) increases with the decrease of film thickness, which leads to the increase of \({\sigma }_{ac}\left(\omega \right)\) with the decrease of film thickness at different temperatures and frequencies. The real \({M}_{1}(\omega )\) and imaginary \({M}_{2}(\omega )\) parts of electric modules were studied, and it was found that the estimated value of the activation energy for the relaxation process \({\Delta E}_{r}\) (0.143 ± 0.002 eV) is thickness independent.

Data availability

All data generated or analyzed during this study are included in this published article.

References

E.A. Davis, N.F. Mott, Philos. Mag. 22, 903 (1970)

M. Pollak, Philos. Mag. 23, 519 (1971)

M. Popescu, F. Sava, A. Velea, A. Lorinczi, J. Non-Cryst. Solids 355, 1820 (2009)

M. Chen, K.A. Rubin, R.W. Barton, Appl. Phys. Lett. 49, 502 (1986)

A. Zakery, S.R. Elliott, J. Non-Cryst. Solids 330, 1 (2003)

N.A. Hegab, A.S. Farid, E. Abd El-Wahabb, H. Magdy, J. Alloys Compd. 743, 36 (2018)

B.J. Eggleton, B. Luther-Davies, K. Richardson, Nat. Photon. 5, 141 (2011)

P.K. Singh, S.K. Sharm, S.K. Tripathi, D.K. Dwivedi, Results Phys. 12, 223 (2019)

Z. Wang, T. Zhang, J. Wang, G. Yang, M. Li, G. Wu, Nanomaterials 12, 446 (2022)

T. Hou, Z. Jia, Y. Dong, X. Liu, G. Wu, Chem. Eng. J. 431, 133919 (2022)

C. Sun, Z. Jia, S. Xu, D. Hu, C. Zhang, G. Wu, J. Mater. Sci. Technol. 113, 128 (2022)

T. Zheng, Z. Jia, Q. Zhan, M. Ling, Y. Su, B. Wang, C. Zhang, G. Wu, Carbon 186, 262 (2022)

Z. Wang, X. Wang, N. Zhao, J. He, S. Wang, G. Wu, Y. Cheng, J. Mater. Sci: Mater. Electron 32, 20973 (2021)

Z. Wang, X. Wang, S. Wang, J. He, T. Zhang, J. Wang, G. Wu, Nanomaterials 11, 1898 (2021)

C. Das, G.M. Rao, S. Asokan, J. Non-Cryst. Solids 357, 165 (2011)

A.C. Galca, F. Sava, I.D. Simandan, C. Bucur, V. Dumitru, C. Porosnicu, C. Mihai, A. Veleaa, J. Non-Cryst. Solids 499, 1 (2018)

E.M. Assim, E.G. El-Metwally, M.M. Abdel-Aziz, Eur. Phys. J. B 92, 276 (2019)

P. Sharma, M.S. El-Bana, S.S. Fouad, V. Sharma, J. Alloys Compd. 667, 204–209 (2016)

H. Kaddouri, S. Bénet, S. Charar, M. Makowaska-Janusik, J.C. Tedenac, I.V. Kityk, Phys. Rev. B 62, 17108 (2000)

E.G. El-Metwally, E.M. Assim, S.S. Fouad, Opt. Laser Technol. 131, 106462 (2020)

A. Sharma, P.B. Barman, Appl. Phys. B 97, 835 (2009)

A. Sharma, P.B. Barman, Phys. Proc. 32, 144 (2012)

K.A. Aly, A.M. AbdElnaeim, M.A.M. Uosif, O. Abdel-Rahim, Physica B 406, 4227 (2011)

A.V. Marchenko, P.P. Seregin, E.I. Terukov, K.B. Shakhovich, Semiconductors 53, 711 (2019)

S.-S. Lin, Ceram. Int. 33, 1161 (2007)

A. Piarristeguy, M. Micoulaut, R. Escalier, G. Silly, M.-V. Coulet, A. Pradel, J. Non-Cryst. Solids 562, 120730 (2021)

Y. Wang, F. Chen, X. Shen, S. Dai, Q. Nie, I. Phys, Technol. 60, 335 (2013)

A. Sharma, P.B. Barman, Defect Diffus. Forum 293, 107 (2009)

H.E. Atyia, N.A. Hegab, M.A. Affi, M.I. Ismail, J. Alloys Compd. 574, 345 (2013)

H.E. Atyia, J. Non-Cryst. Solids 391, 83 (2014)

N.A. Hegab, M.A. Afifi, H.E. Atyia, A.S. Farid, J. Alloys Compd. 477, 925 (2009)

V.K. Bhatnagar, K.L. Bhatia, J. Non-Cryst. Solids 119, 214 (1990)

S.R. Elliot, Solid State Commun. 27, 749 (1978)

S.R. Elliott, Philos. Mag. B 36, 1291 (1977)

A. Ghosh, Phys. Rev. B 41, 1479 (1990)

A. Ghosh, Phys. Rev. B 42, 5665 (1990)

A.R. Long, Adv. Phys. 31, 553 (1982)

S.R. Elliott, Philos. Mag. B 37, 553 (1978)

M. Pollak, T.H. Geballe, Phys. Rev B 122, 1742 (1961)

E.G. El-Metwally, N.A. Hegab, M. Mostfa, Physica B 626, 413556 (2022)

M.A. Afifi, E.G. El-Metwally, N.A. Hegab, M. Mostfa, J. Alloys Compd. 764, 498 (2018)

S. Tolansky, Multiple-Beam Interference Microscopy of Metals (Academic Press, London, 1970), pp. 95–103

A. Tataroğlu, Gazi Univ. J. Sci. 26, 501 (2013)

H.I. Elsaeedy, A. Qasem, M. Mahmoud, H.A. Yakout, S.A. Abdelaal, Opt. Mater. 111, 110693 (2021)

E.M. Assim, E.G. El-Metwally, J. Non-Cryst. Solids 566, 120892 (2021)

V. Vivek Modgil, S. Rangra, S Rangra. Physica B 445, 14 (2014)

I.S. Yahia, N.A. Hegab, A.M. Shakra, A.M. Al-Ribaty, Physica B 407, 2476–2479 (2012)

A.A.A. Darwish, M.M. El-Nahass, A.E. Bekheet, J. Alloys Compd. 586, 142 (2014)

I.G. Austin, N.F. Mott, Adv. Phys. 18, 41 (1969)

S.R. Elliott, Adv. Phys. 36, 135 (1987)

G.E. Pike, Phys. Rev. B 6, 1572 (1972)

N.F. Mott, E.A. Davis, R.A. Street, Philos. Mag. 32, 961 (1975)

E.G. El-Metwally, A.M. Shakra, J. Electron. Mater. 47, 4663 (2018)

K.K. Srivastava, A. Kumar, O.S. Panwar, K.N. Lakshminarayan, J. Non-Cryst. Solids 33, 205 (1979)

M. Barsoum, Fundamentals of Ceramics (McGraw-Hill, New York, 1977), p. 543

J.M. Stevels, The electronic properties of glasses, in Handbuch der Physics. (Springer, Berlin, 1957), p. 350

C.T. Moynihan, Solid State Ionics 105, 175 (1998)

E.R. Shaaban, I.S. Yahia, E.G. El-Metwally, Acta Phys. Polon. A 121, 628 (2012)

D.C. Sati, R. Kumar, R.M. Mehra, Turk. J. Phys. 30, 519 (2006)

P. Sharma, S.C. Katyal, Mater. Lett. 61, 4516 (2007)

D. Prakash, E.R. Shaaban, M. Shapaan, S.H. Mohamed, A.A. Othmane, K.D. Verma, Mater. Res. Bull. 80, 120 (2016)

Z.A. Alrowaili, A. Qasem, E.R. Shaaban, M. Ezzeldien, Physica B 612, 412975 (2021)

A. El-Ghandour, N.A. El-Ghamaz, M.M. El-Nahass, H.M. Zeyada, Physica E 105, 13 (2019)

M.H. Lakhdar, B. Ouni, M. Amlouk, Dielectric relaxation. Mater. Sci. Semicond. Process. 19, 32 (2014)

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The article is original and there is no fund to support the study.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conceptualization, methodology, preparation, investigation, data analysis, writing original draft, reviewing and editing.

Corresponding author

Ethics declarations

Conflict of interest

All the authors have no interest in any financial and personal relationships with other people or organizations that could inappropriately influence (bias) the work reported in this paper. Authors are interested only for academic purposes.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visithttp://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

El-Metwally, E.G., Hegab, N.A. & Mostfa, M. The ac conduction mechanism and dielectric relaxation behavior of amorphous Te81Ge15Bi4 chalcogenide glass thin films. J Mater Sci: Mater Electron 33, 12384–12396 (2022). https://doi.org/10.1007/s10854-022-08196-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08196-8