Abstract

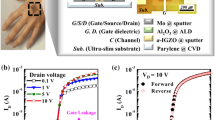

In this study, ITO-coated PET was used as the substrate to create a flexible and transparent structure. a-IGZO (amorphous InGaZnO4) is preferred for the semiconductor layer in order to keep the related TFT device stable at high performance for a long term. In addition, as an innovative method to increase the electrical performance of this TFT, the HfO2 dielectric layer surface has been modified with SrTiO3. All layers of the relevant flexible transparent thin-film transistor (TTFT) structure were produced by the sputtering method. In this work, fabricated TFT devices were evaluated in terms of the structural, morphological, chemical, and optical properties using X-ray diffraction (XRD), scanning electron microscope (SEM), atomic force microscopy (AFM), X-ray photoelectron (XPS), and UV–Vis spectroscopy, respectively. In addition, in order to examine the long-term electrical performance of the related TFT devices, the relevant products were put into the reliability test and their electrical performances before and after the tests were determined. The average optical transmittance values of the developed TFT devices in the wavelength range of 300–700 nm were determined as 79.80%. Before the reliability tests, the maximum fet mobility value was determined as 26.82cm2/Vs. After the reliability tests, it was seen that this value decreased to only 26.27cm2/Vs. The fact that the fet mobility value is so high after long-term stability tests shows that the relevant flexible and transparent TFT device can be used to drive LC (liquid crystal) and OLED (organic light emitting diode) subpixels in LCD and OLED screen technologies.

Similar content being viewed by others

Data availability

The datasets generated during the current study are not publicly available because this study was carried out by VESTEL ELECTRONIC Inc. and the copyright of the inventions developed from this work belongs to VESTEL company. However, if the relevant editors or reviewers of this journal want to see the data, the data can be shared with these people, provided that it is not shared with third parties. In case the data are shared with third parties, legal action will be initiated by VESTEL company.

References

J.S. Meena, M.-C. Chu, C.-S. Wu, F.-C. Chang, F.-H. Ko, Org. Electron. 12, 1414 (2011). https://doi.org/10.1016/j.orgel.2011.05.011

H. Chen, Y. Cao, J. Zhang, C. Zhou, Nat. Commun. 5, 4097 (2014). https://doi.org/10.1038/ncomms5097

G.A. Salvatore, N. Munzenrieder, T. Kinkeldei et al., Nat. Commun. 5, 2982 (2014). https://doi.org/10.1038/ncomms3982

S. Lee, J. Shin, J. Jang, Adv. Func. Mater. (2017). https://doi.org/10.1002/adfm.201604921

Y. Choi, C.K. Song, Org. Electron. 52, 195 (2018). https://doi.org/10.1016/j.orgel.2017.10.030

G. Han, X. Wang, J. Zhang et al., Org. Electron. 52, 213 (2018). https://doi.org/10.1016/j.orgel.2017.10.031

J.W. Jo, K.H. Kim, J. Kim, S.G. Ban, Y.H. Kim, S.K. Park, ACS Appl. Mater. Interfaces 10, 2679 (2018). https://doi.org/10.1021/acsami.7b10786

A. Liu, H. Zhu, H. Sun, Y. Xu, Y.Y. Noh, Adv. Mater. (2018). https://doi.org/10.1002/adma.201706364

J. Jang, D.S. Dolzhnikov, W. Liu, S. Nam, M. Shim, D.V. Talapin, Nano Lett. 15, 6309 (2015). https://doi.org/10.1021/acs.nanolett.5b01258

B. Kim, S. Jang, P.L. Prabhumirashi, M.L. Geier, M.C. Hersam, A. Dodabalapur, Appl. Phys. Lett. (2013). https://doi.org/10.1063/1.4819465

G. He, L. Zhu, Z. Sun, Q. Wan, L. Zhang, Prog. Mater. Sci. 56, 475 (2011). https://doi.org/10.1016/j.pmatsci.2011.01.012

Y. Aoki, T. Kunitake, Adv. Mater. 16, 118 (2004). https://doi.org/10.1002/adma.200305731

H.-H. Hsu, C.-Y. Chang, C.-H. Cheng, Phys. Status Solidi (RRL) 7, 285 (2013). https://doi.org/10.1002/pssr.201307047

L. Xu, N. Gao, Z. Zhang, L.-M. Peng, Appl. Phys. Lett. (2018). https://doi.org/10.1063/1.5039967

E. Carlos, R. Branquinho, A. Kiazadeh et al., ACS Appl. Mater. Interfaces 9, 40428 (2017). https://doi.org/10.1021/acsami.7b11752

J.H. Kim, U.K. Kim, Y.J. Chung, C.S. Hwang, Phys. Status Solidi (RRL) 5, 178 (2011). https://doi.org/10.1002/pssr.201105090

Y. Ko, S. Bang, S. Lee, S. Park, J. Park, H. Jeon, Phys. Status Solidi (RRL) 5, 403 (2011). https://doi.org/10.1002/pssr.201105340

T.S. Kang, K.S. Yoon, G.H. Baek et al., Adv. Electron. Mater. (2017). https://doi.org/10.1002/aelm.201600452

E. W. Forsythe, B. Leever, M. Gordon, et al. IEDM. (2016). https://doi.org/10.1109/IEDM.2015.7409731

M. Mativenga, D. Geng, B. Kim, J. Jang, ACS Appl. Mater. Interfaces 7, 1578 (2015). https://doi.org/10.1021/am506937s

X. Xiao, L. Zhang, Y. Shao, X. Zhou, H. He, S. Zhang, ACS Appl. Mater. Interfaces 10, 25850 (2018). https://doi.org/10.1021/acsami.7b13211

K. Nomura, H. Ohta, A. Takagi, T. Kamiya, M. Hirano, H. Hosono, Nature 432, 488 (2004). https://doi.org/10.1038/nature03090

M. Esro, G. Vourlias, C. Somerton, W.I. Milne, G. Adamopoulos, Adv. Func. Mater. 25, 134 (2015). https://doi.org/10.1002/adfm.201402684

P. Heremans, A.K. Tripathi, A. de Jamblinne de Meux et al., Adv. Mater. 28, 4266 (2016). https://doi.org/10.1002/adma.201504360

G. Gutierrez-Heredia, O. Rodriguez-Lopez, A. Garcia-Sandoval, W.E. Voit, Adv. Electron. Mater. (2017). https://doi.org/10.1002/aelm.201700221

N. Münzenrieder, G. Cantarella, C. Vogt et al., Adv. Electron. Mater. (2015). https://doi.org/10.1002/aelm.201400038

P. Gogoi, R. Saikia, D. Saikia, R.P. Dutta, S. Changmai, Phys. Status Solidi 212, 826 (2015). https://doi.org/10.1002/pssa.201431605

E. Fortunato, R. Barros, P. Barquinha et al., Appl. Phys. Lett. (2010). https://doi.org/10.1063/1.3469939

L.Y. Liang, Z.M. Liu, H.T. Cao et al., J. Electrochem. Soc. (2010). https://doi.org/10.1149/1.3385390

H.-N. Lee, H.-J. Kim, C.-K. Kim, Jpn. J. Appl. Phys. (2010). https://doi.org/10.1143/jjap.49.020202

D. Khim, Y.H. Lin, S. Nam et al., Adv. Mater. (2017). https://doi.org/10.1002/adma.201605837

N. Itagaki, T. Iwasaki, H. Kumomi et al., Phys. Status Solidi 205, 1915 (2008). https://doi.org/10.1002/pssa.200778909

H.Q. Chiang, J.F. Wager, R.L. Hoffman, J. Jeong, D.A. Keszler, Appl. Phys. Lett. (2005). https://doi.org/10.1063/1.1843286

J.S. Park, W.-J. Maeng, H.-S. Kim, J.-S. Park, Thin Solid Films 520, 1679 (2012). https://doi.org/10.1016/j.tsf.2011.07.018

K.P. McKenna, A.L. Shluger, Nat. Mater. 7, 859 (2008). https://doi.org/10.1038/nmat2289

J.F. Cordaro, Y. Shim, J.E. May, J. Appl. Phys. 60, 4186 (1986). https://doi.org/10.1063/1.337504

A. Bolognesi, M. Berliocchi, M. Manenti et al., IEEE Trans. Electron Devices 51, 1997 (2004). https://doi.org/10.1109/ted.2004.838333

V.K. Gueorguiev, T.E. Ivanov, C.A. Dimitriadis, L.I. Popova, S.K. Andreev, Microelectron. J. 31, 207 (2000). https://doi.org/10.1016/S0026-2692(99)00137-8

M. Kimura, T. Yasuhara, K. Harada, D. Abe, S. Inoue, T. Shimoda, J. SID 13, 1027 (2005). https://doi.org/10.1889/1.2150372

S. Rudenja, A. Minko, D.A. Buchanan, Appl. Surf. Sci. 257, 17 (2010). https://doi.org/10.1016/j.apsusc.2010.06.012

B. Psiuk, J. Szade, K. Szot, Vacuum 131, 14 (2016). https://doi.org/10.1016/j.vacuum.2016.05.026

U. Jae Kwang, L. Suhui, J. Seonghyun et al., IEEE Trans. Electron Devices 62, 2212 (2015). https://doi.org/10.1109/ted.2015.2431073

T. Rembert, C. Battaglia, A. Anders, A. Javey, Adv. Mater. 27, 6090 (2015). https://doi.org/10.1002/adma.201502159

H.H. Hsieh, H.H. Lu, H.C. Ting, C.S. Chuang, C.Y. Chen, Y. Lin, J. Inf. Disp. 11, 160 (2010). https://doi.org/10.1080/15980316.2010.9665845

J. Fan, C.-Y. Lee, S.-J. Chen et al., SID Symp. Dig. Tech. Papers 50, 454 (2019)

S. Nakano, N. Saito, K. Miura et al., J. Soc. Inform. Display 20, 493 (2012). https://doi.org/10.1002/jsid.111

Acknowledgements

Synthesis and characterization measurements performed at Dokuz Eylul University, The Center for Fabrication and Applications of Electronic Materials. This research was fully supported by Vestel Electronics and The Scientific and Technical Research Council of Turkey (TUBITAK) under Project No. 3180395. Special Thanks to VESTEL Electronics for their kind and continuous support.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by CO, MFE, SY, and MN. The first draft of the manuscript was written by CO and all authors commented on the previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ozer, C., Ebeoglugil, M.F., Yildirim, S. et al. High-performance a-IGZO-based flexible TTFT with stacked dielectric layers via ultrathin high-κ SrTiO3 buffer layer grown on HfO2. J Mater Sci: Mater Electron 33, 1511–1528 (2022). https://doi.org/10.1007/s10854-021-07662-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07662-z