Abstract

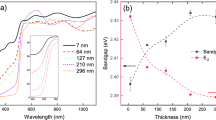

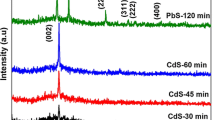

CdS films of different thicknesses (d ≈ 100–300 nm) are deposited on the glass substrate by thermal evaporation technique. The structure of these films had been studied by Rietveld refinement and atomic pressure microscope. The films of CdS/glass show a wurtzite type structure. XRD calculations show that the lattice parameters a and c have changed, the microstrain decreases, and the crystallite size increases. The optical constants refractive index n, and extinction coefficient, k consequently band gap are estimated from SE via construction an optical model. The refractive index n of the CdS/glass films received from SE model increases with growing of CdS layer thickness that is credited to the rise of the size of the crystal. It was also found that when the thickness of the CdS layer increases, the general behavior of the extinction coefficient k of the CdS/glass film increases. In addition, it is found that the direct optical transition with energy band gap is compact from 2.45 (d = 100 nm) eV to 2.25 eV (d = 300 nm). The Ni/n-CdSe/p-CdTe/Pt heterojunction has been assembled. The dark (cutting-edge-voltage) characteristics of fabricated heterojunctions had been suggested at the different thicknesses of CdS, as well as for voltages ranging from − 2 to 2 V. Based on the dependence of the forward and reverse current at the voltage, the powerful and essential parameters related to the fabricated diode had been determined.

Similar content being viewed by others

Data availability

Data supporting the findings of this study are available from the authors upon reasonable request at any time.

Research data policy

It is easy for researchers participating in this research to share data and files that support their publications and give them to any recognized research center or scientific institution that wants these results.

References

J. Han, C. Spanheimer, G. Haindl, G. Fu, V. Krishnakumar, J. Schaffner, C. Fan, K. Zhao, A. Klein, W. Jaegermann, Optimized chemical bath deposited CdS layers for the improvement of CdTe solar cells. Sol. Energy Mater. Sol. Cells 95, 816–820 (2011). https://doi.org/10.1016/j.solmat.2010.10.027

B. Ullrich, J. Tomm, N. Dushkina, Y. Tomm, H. Sakai, Y. Segawa, Photoelectric dichroism of oriented thin film CdS fabricated by pulsed-laser deposition. Solid State Commun. 116, 33–35 (2000). https://doi.org/10.1016/S0038-1098(00)00267-2

R.K. Sharma, K. Jain, A.C. Rastogi, Growth of CdS and CdTe thin films for the fabrication of n-CdS/p-CdTe solar cell. Curr. Appl. Phys. 3, 199–204 (2003). https://doi.org/10.1016/S1567-1739(02)00201-8

X. Mathew, J.P. Enriquez, A. Romeo, A.N. Tiwari, CdTe/CdS solar cells on flexible substrates. Sol. Energy 77, 831–838 (2004). https://doi.org/10.1016/j.solener.2004.06.020

N. Amin, K. Sopian, M. Konagai, Numerical modeling of CdS/CdTe and CdS/CdTe/ZnTe solar cells as a function of CdTe thickness. Sol. Energy Mater. Sol. Cells. 91, 1202–1208 (2007). https://doi.org/10.1016/j.solmat.2007.04.006

H. Kim, D. Kim, Influence of CdS heat treatment on the microstructure of CdS and the performance of CdS/CdTe solar cells. Sol. Energy Mater. Sol. Cells. 67, 297–304 (2001). https://doi.org/10.1016/S0927-0248(00)00295-6

F. Taghizadeh Chari, M.R. Fadavieslam, Microstructural, optical and electrical properties of CdS thin films grown by spray pyrolysis technique as a function of substrate temperature. Opt. Quant. Electron. 51, 377 (2019). https://doi.org/10.1007/s11082-019-2081-8

T.L. Chu, S.S. Chu, Thin film II–VI photovoltaics. Solid State Electron. 38, 533–549 (1995). https://doi.org/10.1016/0038-1101(94)00203-R

F. Rodríguez-Mas, J.C. Ferrer, J.L. Alonso, S. Fernández de Ávila, Expanded electroluminescence in high load CdS nanocrystals PVK-based LEDs. Nanomaterials 9, 1212 (2019). https://doi.org/10.3390/nano9091212

M.A. Buckingham, A.L. Catherall, M.S. Hill, A.L. Johnson, J.D. Parish, Aerosol-assisted chemical vapor deposition of CdS from xanthate single source precursors. Cryst. Growth Des. 17, 907–912 (2017). https://doi.org/10.1021/acs.cgd.6b01795

K. Senthil, D. Mangalaraj, S.K. Narayandass, Structural and optical properties of CdS thin films. Appl. Surf. Sci. 169–170, 476–479 (2001). https://doi.org/10.1016/S0169-4332(00)00732-7

P. Taneja, P. Vasa, P. Ayyub, Chemical passivation of sputter-deposited nanocrystalline CdS thin films. Mater. Lett. 54, 343–347 (2002). https://doi.org/10.1016/S0167-577X(01)00590-0

E.S. Yousef, A. El-Adawy, N. El Koshkhany, E.R. Shaaban, Optical and acoustic properties of TeO2/WO3 glasses with small amount of additive ZrO2. J. Phys. Chem. Solids 67, 1649–1655 (2006). https://doi.org/10.1016/j.jpcs.2006.02.014

M. Baykul, A. Balcioglu, AFM and SEM studies of CdS thin films produced by an ultrasonic spray pyrolysis method. Microelectron. Eng. 51–52, 703–713 (2000). https://doi.org/10.1016/S0167-9317(99)00534-1

M. Tsuji, T. Aramoto, H. Ohyama, T. Hibino, K. Omura, Characterization of CdS thin-film in high efficient CdS/CdTe solar cells. Jpn. J. Appl. Phys. 39, 3902–3906 (2000). https://doi.org/10.1143/JJAP.39.3902

J. Nishino, S. Chatani, Y. Uotani, Y. Nosaka, Electrodeposition method for controlled formation of CdS films from aqueous solutions. J. Electroanal. Chem. 473, 217–222 (1999). https://doi.org/10.1016/S0022-0728(99)00250-8

R. Padmavathy, N. Rajesh, A. Arulchakkaravarthi, R. Gopalakrishnan, P. Santhanaraghavan, P. Ramasamy, Enhancement of photochemical deposition (PCD) and analysis of surface spread of CdS crystalline thin films. Mater. Lett. 53, 321–325 (2002). https://doi.org/10.1016/S0167-577X(01)00500-6

H.M. Rietveld, A profile refinement method for nuclear and magnetic structures. J. Appl. Crystallogr. 2, 65–71 (1969). https://doi.org/10.1107/S0021889869006558

R. A. Young, in The Rietveld Method, International Union Crystallography (Oxford University Press, Oxford, 1993)

R. Devi, P.K. Kalita, P. Purakayastha, B.K. Sarma, Growth and transport properties of nanocrystalline CdS thin film. J. Optoelectron. Adv. Mater. 10, 3077–3082 (2008)

F. Chen, W. Jie, X. Cai, Effects of supersaturation on CdS film growth from dilute solutions on glass substrate in chemical bath deposition process. Thin Solid Films 516, 2823–2828 (2008). https://doi.org/10.1016/j.tsf.2007.04.167

J. Ximello-Quiebras, Physical properties of chemical bath deposited CdS thin films. Sol. Energy Mater. Sol. Cells 82, 263–268 (2004). https://doi.org/10.1016/j.solmat.2004.01.023

B. Sankapal, R. Mane, C. Lokhande, Deposition of CdS thin films by the successive ionic layer adsorption and reaction (SILAR) method. Mater. Res. Bull. 35, 177–184 (2000). https://doi.org/10.1016/S0025-5408(00)00210-5

A.L. Patterson, The Scherrer FORMULA for X-RAY PARTICLE SIZE determination. Phys. Rev. 56, 978–982 (1939). https://doi.org/10.1103/PhysRev.56.978

O.A. Fouad, S.A. Makhlouf, G.A.M. Ali, A.Y. El-Sayed, Cobalt/silica nanocomposite via thermal calcination-reduction of gel precursors. Mater. Chem. Phys. 128, 70–76 (2011). https://doi.org/10.1016/j.matchemphys.2011.02.072

T.K. Pathak, V. Kumar, L.P. Purohit, H.C. Swart, R.E. Kroon, Substrate dependent structural, optical and electrical properties of ZnS thin films grown by RF sputtering. Phys. E: Low-Dimens. Syst. Nanostruct. 84, 530–536 (2016). https://doi.org/10.1016/j.physe.2016.06.020

H. Fujiwara, Spectroscopic ellipsometry: principles and applications, Wiley (2007). https://www.wiley.com/en-us/Spectroscopic+Ellipsometry%3A+Principles+and+Applications-p-9780470016084

M. Alzaid, W.S. Mohamed, M. El-Hagary, E.R. Shaaban, N.M.A. Hadia, Optical properties upon ZnS film thickness in ZnS/ITO/glass multilayer films by ellipsometric and spectrophotometric investigations for solar cell and optoelectronic applications. Opt. Mater. (Amst.) 118, 111228 (2021). https://doi.org/10.1016/j.optmat.2021.111228

M. Emam-Ismail, M. El-Hagary, E.R. Shaaban, S.H. Moustafa, G.M.A. Gad, Spectroscopic ellipsometry and morphological characterizations of nanocrystalline Hg1-xMnxO oxide diluted magnetic semiconductor thin films. Ceram. Int. 45(7), 8380–8387 (2019). https://doi.org/10.1016/j.ceramint.2019.01.146

E.R. Shaaban, M. El-Hagary, M. Emam-Ismail, A. Matar, I.S. Yahia, Spectroscopic ellipsometry and magneto-transport investigations of Mn-doped ZnO nanocrystalline films deposited by a non-vacuum sol–gel spin-coating method. Mater. Sci. Eng. B 178, 183–189 (2013). https://doi.org/10.1016/j.mseb.2012.11.005

G.E. Jellison Jr., Spectroscopic ellipsometry data analysis: measured versus calculated quantities. Thin Solid Films 313–314, 33–39 (1998). https://doi.org/10.1016/S0040-6090(97)00765-7

M. Zhao, R. Tong, X. Chen, T. Ma, J. Dai, J. Lian, J. Ye, Ellipsometric determination of anisotropic optical constants of single phase Ga2O3 thin films in its orthorhombic and monoclinic phases. Opt. Mater. (Amst). 102, 109807 (2020). https://doi.org/10.1016/j.optmat.2020.109807

M. Emam-Ismail, M. El-Hagary, H.M. El-Sherif, A.M. El-Naggar, M.M. El-Nahass, Spectroscopic ellipsometry and morphological studies of nanocrystalline NiO and NiO/ITO thin films deposited by e-beams technique. Opt. Mater. (Amst). 112, 110763 (2021). https://doi.org/10.1016/j.optmat.2020.110763

G.A. Niklasson, C.G. Granqvist, O. Hunderi, Effective medium models for the optical properties of inhomogeneous materials. Appl. Opt. 20, 26 (1981). https://doi.org/10.1364/AO.20.000026

S. Tolansky, Multiple-beam interference microscopy of metals (Academic Press INC LTD, England, 1970)

K. Senthil, D. Mangalaraj, S. Narayandass, S. Adachi, Optical constants of vacuum-evaporated cadmium sulphide thin films measured by spectroscopic ellipsometry. Mater. Sci. Eng. B 78, 53–58 (2000). https://doi.org/10.1016/S0921-5107(00)00510-9

X. Wu, F. Lai, L. Lin, J. Lv, B. Zhuang, Q. Yan, Z. Huang, Optical inhomogeneity of ZnS films deposited by thermal evaporation. Appl. Surf. Sci. 254, 6455–6460 (2008). https://doi.org/10.1016/j.apsusc.2008.04.023

E.R. Shaaban, M. El-Hagary, M. Emam-Ismail, M.B. El-Den, Optical band gap, refractive index dispersion and single-oscillator parameters of amorphous Se 70 S 30–x Sb x semiconductor thin films. Philos. Mag. 91, 1679–1692 (2011). https://doi.org/10.1080/14786435.2010.544683

P. Prathap, N. Revathi, Y.P. Venkata Subbaiah, K.T. Ramakrishna Reddy, Thickness effect on the microstructure, morphology and optoelectronic properties of ZnS films. J. Phys. Condens. Matter. 20, 035205 (2008). https://doi.org/10.1088/0953-8984/20/03/035205

S. Mathew, K.P. Vijayakumar, Ellipsometric studies of microscopic surface roughness of CdS thin films. Bull. Mater. Sci. 17, 421–427 (1994). https://doi.org/10.1007/BF02745230

S. Mathew, P.S. Mukerjee, K.P. Vijayakumar, Optical and surface properties of spray-pyrolysed CdS thin films. Thin Solid Films 254, 278–284 (1995). https://doi.org/10.1016/0040-6090(94)06257-L

J. Tauc, Amorphous and liquid semiconductors (Springer Science & Business Media, Berlin, 2012)

T.K. Tran, W. Park, W. Tong, M.M. Kyi, B.K. Wagner, C.J. Summers, Photoluminescence properties of ZnS epilayers. J. Appl. Phys. 81, 2803–2809 (1997). https://doi.org/10.1063/1.363937

M.S. Bashar, R. Matin, M. Sultana, A. Siddika, M. Rahaman, M.A. Gafur, F. Ahmed, Effect of rapid thermal annealing on structural and optical properties of ZnS thin films fabricated by RF magnetron sputtering technique. J. Theor. Appl. Phys. 14, 53–63 (2020). https://doi.org/10.1007/s40094-019-00361-5

V.H. Choudapur, S.B. Kapatkar, A.B. Raju, Structural and optoelectronic properties of zinc sulfide thin films synthesized by Co-precipitation method. Acta Chem. Iasi 27, 287–302 (2019). https://doi.org/10.2478/achi-2019-0018

N. El-Kabnay, E.R. Shaaban, N. Afify, A.M. Abou-sehly, Optical and physical properties of different composition of InxSe1−x thin films. Phys. B Condens. Matter. 403, 31–36 (2008). https://doi.org/10.1016/j.physb.2007.08.016

O.L. Arenas, M.T.S. Nair, P.K. Nair, Chemical bath deposition of ZnS thin films and modification by air annealing. Semicond. Sci. Technol. 12, 1323–1330 (1997). https://doi.org/10.1088/0268-1242/12/10/022

J. Lee, S. Lee, S. Cho, S. Kim, I.Y. Park, Y.D. Choi, Role of growth parameters on structural and optical properties of ZnS nanocluster thin films grown by solution growth technique. Mater. Chem. Phys. 77, 254–260 (2003). https://doi.org/10.1016/S0254-0584(01)00563-6

A.E. Rakhshani, A.S. Al-Azab, Characterization of CdS films prepared by chemical-bath deposition. J. Phys. Condens. Matter. 12, 8745–8755 (2000). https://doi.org/10.1088/0953-8984/12/40/316

S.A. Al Kuhaimi, Influence of preparation technique on the structural, optical and electrical properties of polycrystalline CdS films. Vacuum 51, 349–355 (1998). https://doi.org/10.1016/S0042-207X(98)00112-2

O. Zelaya-Angel, J.J. Alvarado-Gil, R. Lozada-Morales, H. Vargas, A. Ferreira da Silva, Band-gap shift in CdS semiconductor by photoacoustic spectroscopy: evidence of a cubic to hexagonal lattice transition. Appl. Phys. Lett. 64, 291–293 (1994). https://doi.org/10.1063/1.111184

K.L. Chopra, Thin film phenomena (Krieger Publishing Company, Krieger, 1979)

H. Oumous, H. Hadiri, Optical and electrical properties of annealed CdS thin films obtained from a chemical solution. Thin Solid Films 386, 87–90 (2001). https://doi.org/10.1016/S0040-6090(00)01767-3

A. Segura, K. Wünstel, A. Chevy, Investigation of impurity levels inn-type indium selenide by means of Hall effect and deep level transient spectroscopy. Appl. Phys. A Solids Surf. 31, 139–145 (1983). https://doi.org/10.1007/BF00624719

Acknowledgements

This work was produced with the financial support of the Academy of Scientific Research and Technology of Egypt; ScienceUP/GradeUp initiative: Grant Agreement No (6505). Its contents are the sole responsibility of the authors and do not necessarily reflect the views of the Academy of Scientific Research and Technology.

Author information

Authors and Affiliations

Contributions

ERS: Conceptualization, investigation, calculations, writing—original draft. MAO: Investigation and contribution to writing. AAO: investigation and editing. MMS: Investigation and taking measurements. KIA: Supervising and writing—reviewing and editing.

Corresponding authors

Ethics declarations

This research is in real compliance with ethical standards, because none of the results obtained by the research team contradicts any previously published results.

Conflict of interest

The authors declare that they have no known competing scientific, financial, or personal interests in relationships that could appear to influence the work described in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shaaban, E.R., Osman, M.A., Osman, A.A. et al. Influential role of CdS film thickness in improving CdS/CdTe junction performance for solar cells: structural, optical, and electrical characterizations. J Mater Sci: Mater Electron 33, 4051–4063 (2022). https://doi.org/10.1007/s10854-021-07598-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07598-4