Abstract

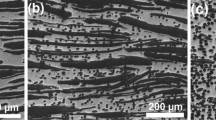

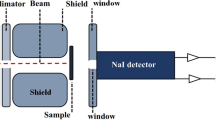

This study produced silicon carbide (SiC) and aluminum oxide (Al2O3) particulates using an in situ reaction system of silicon dioxide (SiO2)+ carbon (C)+ aluminum (A)l with a molten aluminum alloy. The reaction system was examined through differential scanning calorimetry (DSC). The in situ-fabricated aluminum matrix composites (AMCs) were analyzed through X-ray diffraction (XRD), field emission scanning electron microscopy (FESEM), electron backscatter diffraction (EBSD), and transmission electron microscope (TEM). The electromagnetic (EM) shielding effectiveness of the fabricated AMCs was measured in the frequency of 1–5 GHz. The heat flow curve obtained from the DSC analysis revealed the temperature required to attain the reaction. The XRD pattern confirmed the formation of SiC and Al2O3 particulates. FESEM micrographs confirmed that the SiC and Al2O3 particulates were distributed along the intergranular region in the AMCs. The in situ-synthesized submicron-level particulates enhanced the mechanical properties of the composites. The hybrid AMCs exhibited considerable EM shielding effectiveness.

Similar content being viewed by others

Data availability

There is not any data available for this paper.

References

J.P. Immarigeon, R.T. Holt, A.K. Koul, L. Zhao, W. Wallace, J.C. Beddoes, Mater. Charact. 35, 1 (1995)

E. Ghasali, A. Pakseresht, A. Rahbari, H. Eslami-Shahed, M. Alizadeh, T. Ebadzadeh, J. Alloys Compd. 666, 366–371 (2016)

M.O. Bodunrin, K.K. Alaneme, L.H. Chown, J. Mater. Res. Technol. 4, 4 (2015)

T. Shalu, E. Abhilash, M.A. Joseph, J. Mater. Process. Technol. 209, 10 (2009)

E.M. Sharifi, F. Karimzadeh, M.H. Enayati, Mater. Des. 32, 6 (2011)

J.D.R. Selvam, D.R. Smart, I. Dinaharan, Kovove Mater 54, 03 (2016)

J. Liu, Z. Jia, W. Zhou, X. Liu, C. Zhang, B. Xu, G. Wu, Chem. Eng. Sci. 429, 132253 (2022)

Z. Luo, Q. Zhang, X. Ma, G. Wu, Micron. 64, 9 (2014)

P.S. Bains, S.S. Sidhu, H.S. Payal, Mater. Manuf. Process. 31, 1 (2016)

S.L. Pramod, S.R. Bakshi, B.S. Murty, J. Mater. Eng. 24, 6 (2015)

X. Kai, K. Tian, C. Wang, L. Jiao, G. Chen, Y. Zhao, J. Alloys Compd. 668, 121–127 (2016)

A. Pugazhenthi, I. Dinaharan, G. Kanagaraj, J.D.R. Selvam, J. Braz. Soc. Mech. Sci. Eng. 40, 12 (2018)

Z.G. Li, Mater. Lett. 121, 1–4 (2014)

X. Du, T. Gao, G. Liu, X. Liu, J. Alloys Compd. 695, 1–8 (2017)

Z. Dou, G. Wu, X. Huang, D. Sun, L. Jiang, Compos. Part A Appl. Sci. Manuf. 38, 1 (2007)

R. Pandey, S. Tekumalla, M. Gupta, J. Mater. Sci. Mater. Electron. 29, 150–157 (2018)

D.D.L. Chung, Mater. Chem. Phys. 255, 7 (2020)

N. Dong, L. Chen, X. Yin, X. Ma, X. Sun, L. Cheng, L. Zhang, Ceram. Int. 42, 8 (2016)

F. Khodabakhshi, A. Simchi, Mater. Des. 130, 26–36 (2017)

A.K. Singh, A. Shishkin, T. Koppel, N. Gupta, Compos. Part B Eng. 149, 188–197 (2018)

X. Du, T. Gao, D. Li, Y. Wu, X. Liu, J. Alloys Compd. 588, 374–377 (2014)

M. Karbasi, M. Razavi, M. Taheri, D. Vashaee, L. Tayebi, Micro Nano Lett 8, 9 (2013)

P. Wang, L. Cheng, Y. Zhang, L. Zhang, J. Alloys Compd. 716, 306–320 (2017)

A.B. Kheradmand, Z. Lalegani, J. Mater. Sci. Mater. Electron. 26, 10 (2015)

A. Kumar, R.K. Gautam, R. Tyagi, Compos. Interfaces. 23, 6 (2016)

N.N. Lu, X.J. Wang, L.L. Meng, C. Ding, W.Q. Liu, H.L. Shi, X.S. Hu, K. Wu, J. Alloys Compd. 650, 871–877 (2015)

O.A. Elkady, S.A. Abolkassem, A.H. Elsayed, W.A. Hussein, K.F.A. Hussein, Results Phys. 12, 687–700 (2019)

Z. Xu, H. Hao, J Alloy Comp. 617, 207–213 (2014)

Z. Nissar, A. Kazi, M. Safiulla, M. Faisal, Mater. Today Proc. 4, 11 (2017)

X. Sauvage, E.V. Bobruk, M.Yu Murashkin, Y. Nasedkin, N.A. Enikeev, R.Z. Valiev, Acta Materialia, 98 (2015)

B. Feldman, S. Park, M. Haverty, S. Shankar, S.T. Dunham, physica status solidi (b) 247, 7 (2010)

A.F. Mayadas, M. Shatzkes, Phys. Rev. B 1, 4 (1970)

S. Budumuru, in M.S. Anuradha in Microelectronics, Electromagnetics and Telecommunications, ed. by eds. (Bhateja ((Springer, New York, 2019), p. 467

G. Wu, G.X. Huang, Z. Dou, S. Chen, L. Jiang, J. Mater. Sci. 42, 8 (2007)

S. Loya, H. Khan, Int. J. Electro. Magn. Appl. 6, 9 (2016)

Author information

Authors and Affiliations

Contributions

Conceptualization & formal analysis and investigation & resources: TAJMP, writing—original draft preparation & writing—review and editing: JDRS, methodology: ID, and formal analysis: EP.

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pushpa, T., Selvam, J., Dinaharan, I. et al. Electromagnetic interference shielding effectiveness of in situ-synthesized ultrafine SiC- and Al2O3-reinforced AA6061 aluminum matrix composites. J Mater Sci: Mater Electron 33, 3774–3785 (2022). https://doi.org/10.1007/s10854-021-07569-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07569-9