Abstract

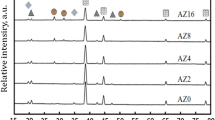

In this research study, Cu–ZrO2/YSZ nanocomposites were synthesized with different volume percentages of stabilized yttrium–zirconia (YSZ) by double-pressing double-sintering method (DPDS). YSZ nanoparticles with specific 1, 2, and 3 vol% were distributed in the Cu powder by planetary ball mill including alumina milling balls of 5 mm diameter. The composite powder obtained from planetary ball mill was then pressed in a uniaxial die of stainless steel under the optimum force of 1000 MPa. Then the pressed pallets pre-sintered and sintered under argon atmosphere by tube furnace at 300–700 °C and 800–950 °C, respectively. The distribution of the reinforcing particles was studied using scanning electron microscopy. Study of the nano-composite microstructures showed that the reinforcing particles were uniformly distributed in the matrix. The optimum amount of the YSZ nanoparticles was determined to be 3%vol. The effects of reinforcing particles and secondary pressing–sintering method on microstructure, density, electrical conductivity, compressive strength, and hardness of nano-composites were also investigated. According to the results, the optimum compression pressure, pre-sintering and sintering temperatures for composites were 1000 MPa, 400 °C, and 850 °C, respectively. Using DPDS method led to the enhancements of about 6% in relative density, 100% in hardness, 8% in electrical conductivity, 70% in abrasion resistance, and 43% compressive strength.

Similar content being viewed by others

References

T. Clyne, P. Withers, An Introduction to Metal Matrix Composites (Cambridge University Press, Cambridge, 1995)

A. Fathy, O. Elkady, A. Abu-Oqail, Synthesis and characterization of Cu–ZrO2 nanocomposite produced by thermochemical process. J. Alloy. Compd. (2017). https://doi.org/10.1016/j.jallcom.2017.05.209

M. Akbarpour et al., Microstructural development and mechanical properties of nanostructured copper reinforced with SiC nanoparticles. Mater. Sci. Eng. A 568, 33–39 (2013)

F. Akhtar et al., Microstructure, mechanical properties, electrical conductivity and wear behavior of high volume TiC reinforced Cu-matrix composites. Mater. Charact. 60(4), 327–336 (2009)

M. Khaloobagheri, B.S. Abdollahi, The effect of milling time on properties and microstructure of Cu-yttria stabilized zirconia composites fabricated by powder metallurgy. J. Mater. Sci. Appl. 1, 78–84 (2015)

G.C. Efe, M. Ipek, S. Zeytin, C. Bindal, An investigation of the effect of the SiC particle size on the Cu–SiC composites. Compos. B Eng. 43(4), 1813–1822 (2012)

G.C. Efe, T. Yener, I. Altinsoy, M. Ipek, S. Zeytin, C. Bindal, The effect of the sintering temperature on the some properties of the Cu–SiC composite. J. Alloy. Compd. 509(20), 6036–6042 (2011)

M. Akbarpour et al., Effect of nanoparticle content on the microstructural and mechanical properties of nano-SiC dispersed bulk ultra-grained Cu matrix composites. Mater. Des. 52, 881–887 (2013)

R. Ritasalo et al., Microstructural and mechanical characteristics of Cu–Cu2O composites compacted with pulsed electric current sintering and hot iso-static pressing. Compos. Appl. Sci. Manufact. 45, 61–69 (2013)

R.M. German, Powder Metallurgy and Particulate. Metal Powder (Princeton, Industries Federation, 2005)

F. Shehata et al., Preparation and properties of Al2O3 nanoparticle reinforced copper matrix composites by in situ processing. Mater. Des. 30(7), 2756–2762 (2009)

A. Fathy et al., Compressive and wear resistance of nano-metric alumina reinforced copper matrix composites. Mater. Design (1980–2005) 36, 100–107 (2012)

G. Lepure et al., Effect of ZrO2 particles upon Cu-ZrO2 material used for the spot welding electrodes. Metall. Int. 14(6), 21–25 (2009)

R. Shimansky, Double Press and Double Sinter in Metal Powder Report (Pennsylvania, Bucknell, 1992)

N. Chawla, K. Chawla, Metal-matrix. J. Min. Met. Mater. Soc. 58(11), 67–70 (2006)

S.A.A. Alem, R. Latifi, S. Angizi, N. Mohamadbeigi, M. Rajabi, E. Ghasali, Y. Orooji, Development of metal matrix composites and nanocomposites via double-pressing double-sintering (DPDS) method. Mater. Today Commun. (2020). https://doi.org/10.1016/j.mtcomm.2020.101245

I. Celikyurek et al., Microstructure, properties and wear behaviors of (Ni3Al) P reinforced Cu matrix composites. J. Mater. Sci. Technol. 27(10), 937–943 (2011)

J. Tu et al., Preparation and properties of TiB2 nanoparticle reinforced copper matrix composites by in situ processing. Mater. Lett. 52(6), 448–452 (2002)

W.F. Hosford, Mechanical Behavior of Materials (Cambridge University Press, New York, 2010)

G.E. Dieter, Mechanical Metallurgy (Mc-Graw Hill Inc, New York, 1986)

A. Santos-Beltrn et al., Mechanical & microstructural characterizationof the dispersion of the strengthened-AlC system nanocomposites. J. Alloys Compd. 489, 626–630 (2010)

R. Casati, M. Vedani, The metal matrix composites reinforced by nanoparticles. A review. Metals 4, 65–83 (2014)

M. Rajabi, M.M. Khodai, N. Askari, Microwave-assisted sintering of Al–ZrO2 nano-composites. J. Mater. Sci. Mater. Electron. 25, 4577–4584 (2014)

Z. Asadipanah, M. Rajabi, Production of Al–ZrB2 nano-composites by microwave sintering process. J. Mater. Sci. Mater. Electron. 26(8), 6148–6156 (2015)

A. Yarahmadi, M.T. Noghani, M. Rajabi, Effect of carbon nanotube (CNT) content and double-pressing double sintering (DPDS) method on the tensile strength and bending strength behavior of CNT-reinforced aluminum composites. J. Mater. Res. 31(24), 3860–3868 (2016)

M.M. Khodai, M. Rajabi, N. Askari, B. Mirhadi, H. Oveisi, Microwave sintering of aluminum-zirconia nano-composites. In: 2nd International Advances in Applied Physics and Materials Science Congress, Antalya, pp. 125–132 (2012)

M. Rajabi, M. Safaei, Synthesis of Al-SiC composite material by double-pressing double–sintering method. In: 4th Annual Congress of Iranian Metallurgy Engineering Society, Tehran, pp. 995–1004 (1999)

A. Yarahmadi, M. Rajabi, M. Talafi Noghani, R. Taghiabadi, Synthesis of aluminum–CNTs composites using double-pressing double-sintering method. J. Nanostruct. 9(1), 95–103 (2019)

M. Darabi, M. Rajabi, Electrical and mechanical properties of Cu–CNT nanocomposites sintered by microwave technique. Metall. Mater. Eng. 23(4), 303–317 (2017)

D. Marjan, M. Rajabi, Synthesis of Cu-CNTs, nanocomposites via double pressing double sintering method. Metall. Mater. Eng. 31(4), 319–334 (2017)

D. Marjan, M. Rajabi, B. Junipour, M. Talafi-Noghani, The effect of sintering temperature on Cu–CNTs nano-composites properties produced by PM method. Sci. Sinter. J. 50, 477–486 (2018)

M.R. Pouyani, M. Rajabi, Microwave-assisted synthesis of Cu-ZrB2 MM Nano-composite using double pressing double sintering method. J. Mater. Sci. 30, 266–276 (2019)

M. Darabi, N. Nasiri, M. Rajabi, Microstructural, mechanical and thermal properties of microwave sintered Cu-MWCNT nano-composites. J. Alloy. Compd. (2020). https://doi.org/10.1016/j.jallcom.2020.153675

M. Rajabi, R. Moradiclardeh, S.M. Mosavian, Synthesis of Al– ZrO2 composite materials by the stir-casting method. In: Iran International Aluminum Conference, Tehran, 2009.

Acknowledgements

The authors would like to thank INSF of Iran (Contract Number: 93006640) for the full financial support of the research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare the following financial interests/personal relationships which may be considered as potential competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Najafi, A., Rajabi, M., Baghshahi, S. et al. Physical properties and microstructural characterization of copper–ZrO2/YSZ nano-composites produced via double-pressing double-sintering method (DPDS). J Mater Sci: Mater Electron 32, 28307–28320 (2021). https://doi.org/10.1007/s10854-021-07207-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07207-4