Abstract

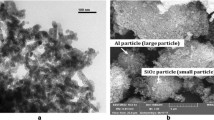

In this project, nano-ZrO2 particles were dispersed in aluminum powder by a Y-shape mixer. The particle size of ZrO2 powder was <40 nm and the amount of ZrO2 reinforcement varies from 3 to 15 %. The mixed powders were compacted. Subsequently the compacted discs were sintered both in the microwave oven and in the conventional muffle furnace. Using microwave-assisted sintering method led to the reduction of sintering time to 15 min. Micro-structural studies of the nano-composites indicated that there is relatively uniform distribution of the reinforcement in the matrix. Aluminum metal matrix nano-composites samples were characterized by micro-hardness measurements, optical microscopy, X-ray diffraction, scanning electron microscopy and energy dispersive X-ray analysis. Mechanical properties reveal that the presence of nano-ZrO2 particles has improved significantly the strength. The optimum amount of ZrO2 reinforcement has been determined to be 6 %.

Similar content being viewed by others

References

M. Rajabi, Characterization of Al–SiC composite materials produced by double pressing–double sintering method. Int. J. Eng. Sci. 14(2),89–110, (Spring 2003)

M. Rajabi, M.M. Khodai, N. Askari, B. Mirhadi, H. Oveisi, in Evaluation of Time Effect on Mechanical Properties of Al–ZrO 2 Nano-Composites Produced by Microwave Sintering. Iran International Aluminum Conference, Arak, Iran (2012)

M.M. Khodai, M. Rajabi, N. Askari, B. Mirhadi, H. Oveisi, in Microwave Sintering of aluminum–Zirconia nano-Composites, 2nd International Advances in Applied Physics and Materials Science Congress, Antalya, Turkey (2012)

M. Rajabi, R. Moradiclardeh, S.M. Mosavian, in Synthesis of Al–ZrO 2 Composite Materials by the Stir-Casting Method, Iran International Aluminum Conference, Tehran, Iran (2009)

A.J. Cheng, D.A. Zhang, R. Roy, Microwave reactive sintering to fully transparent aluminum oxy nitride (ALON) ceramics. J. Mater. Sci. Lett. 20, 77–79 (2001)

T.T. Meek, C.E. Holcomband, N. Dykes, Microwave sintering of some oxide materials using sintering aids. J. Mater. Sci. Lett. 6(9), 1060–1062 (1987)

H.D. Kimrey, J.O. Kiggans, M.A. Janney, R.L. Beatty, Microwave sintering of zirconia-toughened alumina composites in microwave processing of materials II. J. Mater. Res. Soc. Symp. Proc. 189, 243–256 (1991)

M.O. Mizuno, Sintering of traditional ceramics by microwave. J. Ceram. Trans. 111, 277–285 (2001)

Z. Xie, J. Yang, X. Huang, Y. Huang, Microwave processing and properties of ceramics with different dielectric loss. J. Mater. Sci. Eng. 19, 381–387 (1999)

M. Elsagh, M. Rajabi, E. Amini, Characterization of SrAl2O4: Eu2+, Dy3+ phosphor nano-powders produced by microwave synthesis route. J. Mater. Electron. 25, 1612–1619 (2014). doi:10.1007/s10854-014-1773-x

S.J. Garcia, C.S.L. Cajun, R. Fuentes, V.M. Castano, Synthesis of an Al–ZrO2 composite by infiltration of Zr-chelates into an Al matrix. Mater. Res. Innovat. 5(3), 199–204 (2003)

M.N. Rahaman, Ceramic Processing and Sintering, Dekker, 2nd edn (2003)

F. Hajiakbari, Z. Bagherifard, H. Sarpoolaki, B. Eftekhari Yekta, Microstructure evaluation of Al–Mg–SiC composite through sintering by microwave and electrical furnace. J. Mater. Eng. 1(3), 219–230 (2009)

M.K. Surappa, in Aluminum Matrix Composites: Challenges and Opportunities, Sadhana Printed in India, vol. 28, parts 1 and 2 (2003) pp. 319–334

ASM Handbook, vol. 21, Composites (ASM International, USA, 2001)

T. Ebadzadeh, M. Valefi, Microwave-assisted sintering of zircon. J.Alloys Compd. 448, 246–249 (2008)

M. Rajabi, M. Safaei, in Synthesis of Al–SiC Composite Material by Double-Pressing Double-Sintering Method, 4th Annual Congress of Iranian Metallurgy Engineering Society (1999) pp. 995–1004

M.A. Baghchesara, H. Abdizadeh, H.R. Baharvandi, Fractography of stir casting Al–ZrO2 composites. Iran. J. Sci. Technol. Trans. B Eng. 33(B5), 453–462 (2009)

S. Suresh, A. Mortensen, A. Needleman, in Fundamentals of Metal-Matrix Composites, Butterworth-Heinemann (1993) pp. 1–326

J.M. Torralbaa, C.E. da Costab, F. Velasco, P/M aluminum matrix composites: an over view. J. Mater. Process. Technol. 133, 203–206 (2003)

J. Hemanth, Development and property evaluation of aluminum alloy reinforced with nano-ZrO2 metal matrix composites (NMMCs). Mater. Sci. Eng., A 507, 110–113 (2009)

R.F. Ramirez, A.P. Gonzalez, V.M.C. Meneses, Improved wear resistance of an aluminum–zirconia composite. Metal Sci. Heat Treat. 52(7–8), 368–370 (2010)

M.T. Abou-El-Khair, A. AbdelAli, Erosion–corrosion and surface protection of A356 Al/ZrO2 composites produced by vortex and squeeze casting. Mater. Sci. Eng., A 454–455, 156–163 (2007)

D.R. Ye, J.H. Hu, Hand book of thermodynamics data for in organic substance (Metallurgy Industry Press, Beijing, 2002), pp. 27–72

O. Knacke, Thermo-chemical properties of inorganic substances (Springer-Verlag, Berlin, 1991), pp. 30–150

H. Zhu, J. Min, J. Li, Y. Ai, L. Ge, H. Wang, In situ fabrication of (α-Al 2O3 + Al 3Zr)/Al composites in an Al–ZrO2 system. Compos. Sci. Technol. 70(15), 2183–2189 (2010)

J.K. Jain, S.P. Gupta, Inter-metallic compound formation in the Zr–Al–Si ternary system. Mater. Charact. 49, 139–148 (2003)

A.S.M. Handbook, Alloy phase diagram, vol. 3 (ASM International, USA, 1992)

A.S.M. Handbook, Powder metallurgy, vol. 7 (ASM International, USA, 1984)

T.S. Srivatsan, I.A. Ibrahim, F.A. Mohamed, E.J. Lavernia, Processing techniques for particulate-reinforced metal aluminum matrix composites. J. Mater. Sci. 26, 5965–5978 (1991)

D.B. Miracle, Metal matrix composites—from science to technological significance. Compos. Sci. Technol. 65, 2526–2540 (2005)

A. Erol, A. Yonetken, I. Yildiz, M. Erdogan, in Fabrication of Ni Metal Matrix Composites Reinforced with SiO 2 by Microwave Sintering, 5th International Advanced Technologies Symposium (IATS’09), Karabuk, Turkey, May 13–15 (2009)

P.G. Karandikar, M.K. Aghajanian, D. Agrawal, J. Cheng, Microwave assisted (MASS) processing of metal–ceramic and reaction-bonded composites. Ceram. Eng. Sci. Proc. 27(2), 435–446 (2007)

H.G. Zhu, Y.L. Ai, J. Min, Q. Wu, H.Z. Wang, Dry sliding wear behavior of Al-based composites fabricated by exothermic dispersion reaction in an Al–ZrO2–C system. Wear 268, 1465–1471 (2010)

D.R. Sahu, B.K. Roul, S.K. Singh, R.N.P. Choudhury, Studies on dielectric properties of Al–Zr oxide composites sintered by thermal plasma. Mater. Lett. 56, 817–821 (2002)

P.V. Krakhmalev, E. Strom, M. Sundberg, C. Li, Microstructure, hardness and indentation toughness of C40 Mo (Si, Al)2/ZrO2 composites prepared by SPS of MA powders. Scripta Mater. 48, 725–729 (2003)

P.V. Krakhmalev, Preparation of Mo(Si, Al)2–ZrO2 nano-composite powders by mechanical alloying. Int. J. Refract Metal Hard Mater. 22, 205–209 (2004)

Z. Wang, X. Liu, Reaction in the Al–ZrO2–C system. J. Mater. Sci. 40, 4727–4735 (2005)

E. Bayraktar, D. Katundi, Development of a new aluminum matrix composite reinforced with iron oxide (Fe 3O4). J. Achiev. Mater. Manuf. Eng. 38, 7–14 (2010)

S. Leparoux, S. Vaucher, O. Beffort, Assessment of microwave heating for sintering of Al/SiC and for in situ synthesis of TiC. Adv. Eng. Mater. 8(4), 449–453 (2003)

Z. Huanga, M. Gotohb, Y. Hiroseb, Improving sinterability of ceramics using hybrid microwave heating. J. Mater. Process. Technol. 209, 2446–2452 (2009)

K. Rajkumar, S. Aravindan, Microwave sintering of copper–graphite composites. J. Mater. Process. Technol. 209, 5601–5605 (2009)

E. Brevala, J.P. Chenga, D.K. Agrawala, P. Gigla, M. Dennisb, R. Roya, A.J. Papworth, Comparison between microwave and conventional sintering of WC/Co composites. Mater. Sci. Eng., A 391, 285–295 (2005)

Y.V. Naidich, V.S. Zhuravlev, I.I. Gab, B.D. Kostyuk, V.P. Krasovskyy, A.A. Adamovskyy, NYu. Taranets, Liquid metal wettability and advanced ceramic brazing. J. Eur. Ceram. Soc. 28, 717–728 (2008)

R. Bauri, Trans. the Indian Inst. Metals 62(4–5), 391–392 (2008)

Acknowledgments

The authors acknowledge the financial support of Deputy for Research and Technology of Imam Khomeini International University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajabi, M., Khodai, M.M. & Askari, N. Microwave-assisted sintering of Al–ZrO2 nano-composites. J Mater Sci: Mater Electron 25, 4577–4584 (2014). https://doi.org/10.1007/s10854-014-2206-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-2206-6