Abstract

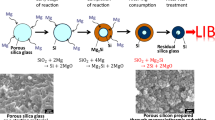

The cycling stability and rate performance of anode materials should be increased to meet the demands for automotive power batteries with a long-life and fast charging capability. In this study, a silica/graphite anode material was synthesized in situ via a hydrolysis-calcination route using ethyl orthosilicate as the silicon source. The morphology and structure of silica/graphite anode materials were examined by SEM, XRD, and XPS techniques. The electrochemical properties of silica/graphite materials were investigated by galvanostatic charge–discharge, cyclic voltammetry and electrochemical impedance spectroscopy techniques. The results showed that amorphous silica microspheres were embedded in the graphite matrix. This structure not only strengthened the bonding of Si–O–C but also improved the composition of the solid-electrolyte interphase. The specific capacity of the silica/graphite anode material could be stabilized at approximately 450 mAh g−1 after 300 cycles at a current density of 100 mA g−1, resulting in stable lithium storage due to the synergistic effect between the silica and graphite.

Similar content being viewed by others

Availability of data and material

The data supporting the results of this article are included within this article.

References

X. Guo, S. Wang, B. Yang, Y. Xu, Y. Liu, H. Pang, Porous pyrrhotite Fe7S8 nanowire/SiOx/nitrogen-doped carbon matrix for high-performance Li-ion-battery anodes. J. Colloid Interface Sci. 561, 801–807 (2020)

J. Song, S. Guo, L. Kou, K. Kajiyoshi, J. Su, W. Huang, Y. Li, P. Zheng, Controllable synthesis Honeycomb-like structure SiOx/C composites as anode for high-performance lithium-ion batteries. Vacuum 186, 110044 (2021)

B. Ding, Z. Ahsan, X. Huang, Z. Cai, Y. Ma, G. Song, W. Yang, C. Wen, Preparation and electrochemical properties of high capacity silicon-based composites for lithium-ion batteries. Synth. Met. 261, 116324 (2020)

K. Chen, V. Goel, M.J. Namkoong, M. Wied, S. Müller, V. Wood, J. Sakamoto, K. Thornton, N.P. Dasgupta, Enabling 6C fast charging of Li-ion batteries with graphite/hard carbon hybrid anodes. Adv. Energy Mater. 11(5), 2003336 (2021)

U.S. Im, J.U. Hwang, J.H. Yun, W. Ahn, K.S. Kim, J.S. Im, The effect of mild activation on the electrochemical performance of pitch-coated graphite for the lithium-ion battery anode material. Mater. Lett. 278, 128421 (2020)

S.S. Lee, C.M. Park, Amorphous silicon dioxide-based composites for high-performance Li-ion battery anodes. Electrochim. Acta 284, 220–225 (2018)

Q. Zhao, W. Xiao, X. Yan, S. Qin, B. Qu, L. Zhao, Effect of pyrolytic polyacrylonitrile on electrochemical performance of Si/graphite composite anode for lithium-ion batteries. Ionics 23(7), 1685–1692 (2017)

M. Pan, X. Liu, H. Liu, Y. Chen, Ultrafine Si/C-graphite composite anode materials with improved cyclic performance. Mater. Lett. 178, 252–255 (2016)

Y. Yang, Z. Wang, Y. Zhou, H. Guo, X. Li, Synthesis of porous Si/graphite/carbon nanotubes@C composites as a practical high-capacity anode for lithium-ion batteries. Mater. Lett. 199, 84–87 (2017)

X. Liu, C. Xing, F. Li, J. Qu, C. Wang, C. Lai, In situ-derived porous SiO2/carbon nanocomposite from lichens for lithium-ion batteries. Energy Technol. 7(8), 1800840 (2019)

J. Li, S. Yang, H. Zhou, L. Wang, Z. Yang, P. Meng, L. Hu, R. Hu, Facile synthesis of SiO2/C anode using PVC as carbon source for lithium-ion batteries. J. Mater. Sci.: Mater. Electron. 30, 69–78 (2019)

C. Yang, J. Shih, M. Wu, Preparation of silicon oxide coated KS-6 graphite composite anode materials by sol-gel method in lithium ion batteries. Energy Procedia 61, 1428–1433 (2014)

L. Zhang, K. Shen, W. He, Y. Liu, S. Guo, SiO2@graphite composite generated from sewage sludge as anode material for lithium ion batteries. Int. J. Electrochem. Sci. 12(11), 10221–10229 (2017)

H. Li, L. Zhang, C. Fan, K. Wang, X. Wu, H. Sun, J. Zhang, A plum-pudding like mesoporous SiO2/flake graphite nanocomposite with superior rate performance for LIB anode materials. Phys. Chem. Chem. Phys. 17, 22893–22899 (2015)

J.S. Kim, C.C. Nguyen, H.J. Kim, S.W. Song, Siloxane-capped amorphous nano-SiOx/graphite with improved dispersion ability and battery anode performance. RSC Adv. 4(25), 12878–12881 (2014)

Y. Yang, W. Peng, H. Guo, Z. Wang, X. Li, Y. Zhou, Y. Liu, Effects of modification on performance of natural graphite coated by SiO2 for anode of lithium ion batteries. Trans. Nonferrous Met. Soc. China 17(6), 1339–1342 (2007)

S. Fei, Y. Zhang, J. Zhang, Z. Tang, Q. Wu, Continuous synthesis of monodisperse silica microspheres over 1 μm size. J. Flow Chem. (2021). https://doi.org/10.1007/s41981-021-00157-2

L. Cao, J. Huang, Z. Lin, X. Yu, X. Wu, B. Zhang, Y. Zhan, F. Xie, W. Zhang, J. Chen, H. Meng, Amorphous SiO2/C composite as anode material for lithium-ion batteries. J. Mater. Res. 33(9), 1219–1225 (2018)

M. Jiao, K. Liu, Z. Shi, C. Wang, SiO2/carbon composite microspheres with hollow core-shell structure as a high-stability electrode for lithium-ion batteries. ChemElectroChem 4(3), 542–549 (2017)

S. Ali, S. Jaffer, I. Maitlo, F.K. Shehzad, Q. Wang, S. Ali, M.Y. Akram, Y. He, J. Nie, Photo cured 3D porous silica-carbon (SiO2-C) membrane as anode material for high performance rechargeable Li-ion batteries. J. Alloy Compd. 812, 152127 (2019)

Z. Gu, X. Xia, C. Liu, X. Hu, Y. Chen, Z. Wang, H. Liu, Yolk structure of porous C/SiO2/C composites as anode for lithium-ion batteries with quickly activated SiO2. J. Alloy Compd. 757, 265–272 (2018)

H. Xia, Z. Yin, F. Zheng, Y. Zhang, Facile synthesis of SiO2 /C composites as anode materials for lithium-ion batteries. Mater. Lett. 205, 83–86 (2017)

W.S. Chang, C.M. Park, J.H. Kim, Y.U. Kim, G. Jeong, H.J. Sohn, Quartz (SiO2): a new energy storage anode material for Li-ion batteries. Energy Environ. Sci. 5(5), 6895–6899 (2012)

J. Guo, W. Zhai, Q. Sun, Q. Ai, J. Li, J. Cheng, L. Dai, L. Ci, Facilely tunable core-shell Si@SiOx nanostructures prepared in aqueous solution for lithium ion battery anode. Electrochim. Acta 342, 136068 (2020)

C. Li, X. Zhang, K. Wang, X. Sun, Y. Ma, A 29.3 Wh kg−1 and 6 kW kg−1 pouch-type lithium-ion capacitor based on SiOx/graphite composite anode. J. Power Sources 414, 293–301 (2019)

H. Pang, W. Zhang, P. Yu, N. Pan, H. Hu, M. Zheng, Y. Xiao, Y. Liu, Y. Liang, Facile synthesis of core-Shell structured SiO2@carbon composite nanorods for high-performance lithium-ion batteries. Nanomaterials 10(3), 513 (2020)

J. Qin, M. Wu, T. Feng, C. Chen, C. Tu, X. Li, C. Duan, D. Xia, D. Wang, High rate capability and long cycling life of graphene-coated silicon composite anodes for lithium ion batteries. Electrochim. Acta 256, 259–266 (2017)

S. Hao, Z. Wang, L. Chen, Amorphous SiO2 in tunnel-structured mesoporous carbon and its anode performance in Li-ion batteries. Mater. Des. 111, 616–621 (2016)

X. Liu, Y. Chen, H. Liu, Z. Liu, SiO2@C hollow sphere anodes for lithium-ion batteries. J. Mater. Sci. Technol. 33(3), 239–245 (2016)

Y. Ren, B. Yang, H. Wei, J. Ding, Electrospun SiO2/C composite fibers as durable anode materials for lithium ion batteries. Solid State Ionics 292, 27–31 (2016)

Acknowledgements

This work was financially supported by National Natural Science Foundation of China (No. 52172063), Excellent Youth Research Project from Hunan Provincial Education Department (No. 19B038), Natural Science Foundation of Hunan Province (Nos. 2020JJ4094, 2021JJ30724), and National Undergraduate Innovation Training Program of China (No. 202110536005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liang, J., Yang, S., Ye, L. et al. In situ synthesis of silica/graphite anode material with enhanced lithium storage performance. J Mater Sci: Mater Electron 32, 28119–28128 (2021). https://doi.org/10.1007/s10854-021-07187-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07187-5