Abstract

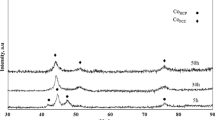

A multicomponent with functional Fe50Ni10Co10Ti10B20 (at.%) high entropy soft magnetic alloy powders were produced from the elemental powders by mechanical alloying (MA). The MA processes were carried out under argon gas atmosphere at a speed of 250 rpm, carrying milling and rest in every 20-min period to prevent the mixture from overheating. Scanning electron microscopy and energy-dispersive X-ray spectroscopy, X-ray diffraction, differential thermal analysis, and vibrating sample magnetometer analysis were utilized to characterize various powdered samples with respect to MA time (0–50 h). The results show that in the first 2.5 h of MA, the mixture of crystalline phases transformed into a nanocrystalline supersaturated α-Fe solid solution phase. With prolonging milling time, the amorphous phase appeared after 20 h of MA. In the final stage of MA (50 h), the saturation magnetization (Ms) and the coercivity (Hc) were 89.7 emu/g and 32.5 Oe, respectively, proposing the alloy as a very good high entropy soft magnet in nature.

Similar content being viewed by others

References

N. Ma, S. Liu, W. Liu, L. Xie, D. Wei, L. Wang, L. Li, B. Zhao, Y. Wang, Research progress of titanium-based high entropy alloy: methods, properties, and applications. Front Bioeng Biotechnol 8(1–18), 603522 (2020)

S. Gorsse, J.-P. Couzinié, D.B. Miracle, From high-entropy alloys to complex concentrated alloys. C. R. Physique 19, 721–736 (2018)

B. Avar, T. Simsek, S. Ozcanc, A.K. Chattopadhyay, B. Kalkan, Structural stability of mechanically alloyed amorphous (FeCoNi)70Ti10B20 under high-temperature and high-pressure. J. Alloys Compds. 860(1–9), 158528 (2020)

N. Birbilis, S. Choudhary, J.R. Scully, M.L. Taheri, A perspective on corrosion of multi-principal element alloys. Npj Mater. Degrad. 5(1–14), 14 (2021)

Y. Yin, J. Zhang, Q. Tan, W. Zhuang, N. Mo, M. Bermingham, M.-X. Zhang, Novel cost-effective Fe-based high entropy alloys with balanced strength and ductility. Mater. Des. 162, 24–33 (2019)

L. Sang, Y. Xu, Amorphous behavior of ZrxFeNiSi0.4B0.6 high entropy alloys synthesized by mechanical alloying. J. Non-Cryst. Solids 530(1–7), 119854 (2020)

D.B. Miracle, O.N. Senkov, A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448–511 (2017)

M.-H. Tsai, J.-W. Yeh, High-entropy alloys: a critical review. Mater. Res. Lett. 2(3), 107–123 (2014)

S.Y. Lee, S. Byeon, H.S. Kim, H. Jin, S. Lee, Deep learning-based phase prediction of high-entropy alloys: optimization, generation, and explanation. Mater. Des. 197(1–16), 109260 (2021)

G.J. Naz, D. Dong, Y. Geng, Y. Wang, C. Dong, Composition formulas of Fe-based transition metals-metalloid bulk metallic glasses derived from dualcluster model of binary eutectic. Sci. Rep. 7(1–11), 9150 (2017)

Z.-Q. Zhang, K.-K. Song, S. Guo, Q.-S. Xue, H. Xing, C.-D. Cao, F.-P. Dai, B. Völker, A. Hohenwarter, T. Maity, N. Chawake, J.-T. Kim, L. Wang, I. Kaban, J. Eckert, Optimizing mechanical properties of Fe26.7Co26.7Ni26.7Si8.9B11 high entropy alloy by inducing hypoeutectic to quasi-duplex microstructural transition. Sci. Rep. 9(1–14), 360 (2019)

Y. Zhang, M. Zhang, D. Li, T. Zuo, K. Zhou, M.C. Gao, B. Sun, T. Shen, Compositional design of soft magnetic high entropy alloys by minimizing magnetostriction coefficient in (Fe0.3Co0.5Ni0.2)100–x(Al1/3Si2/3)x system. Metals 9(1–12), 382 (2019)

M.E. McHenry, M.A. Willard, D.E. Laughlin, Amorphous and nanocrystalline materials for applications as soft magnets. Prog. Mater. Sci. 44, 291–433 (1999)

A. Inoue, T. Zhang, H. Koshiba, A. Makino, New bulk amorphous Fe–(Co, Ni)–M–B (M=Zr, Hf, Nb, Ta, Mo, W) alloys with good soft magnetic properties. J. Appl. Phys. 83, 6326–6328 (1998)

W. Li, P. Liu, P.K. Liaw, Microstructures and properties of high-entropy alloy films and coatings: a review. Mater. Res. Lett. 6(4), 199–229 (2018)

H. Raanaei, V. Mohammad-Hosseini, Morphology and magnetic behavior of cobalt rich amorphous/nanocrystalline (Co–Ni)70Ti10B20 alloyed powders. J. Magn. Magn. Mater. 414, 90–96 (2016)

C. Suryanarayana, Mechanical alloying and milling. Prog. Mater Sci. 46, 1–184 (2001)

T. Simsek, B. Avar, S. Ozcan, A.K. Chattopadhyay, B. Kalkan, Solid-state synthesis and characterization of the stable nanostructured Ni21Ti2B6 phase. Phys. Status Solidi B 258(5), 2000571 (2021)

C. Suryanarayana, E. Ivanov, in Advances in Powder Metallurgy: Properties, Processing and Applications, ed. by I. Chang, Y. Zhao (Woodhead Publishing, Cambridge, 2013), p. 42

S. G. Sarwat, Contamination in wet-ball milling. Powder Metall. 60(4), 267–272 (2017)

F.C. Li, T. Liu, J.Y. Zhang, S. Shuang, Q. Wang, A.D. Wang, J.G. Wang, Y. Yang, Amorphous–nanocrystalline alloys: fabrication, properties, and applications. Mater. Today Adv. 4(1–20), 100027 (2019)

G. Herzer, Modern soft magnets: Amorphous and nanocrystalline materials. Acta Mater. 61, 718–734 (2013)

K. Suzuki, G. Herzer, in Advanced Magnetic Nanostructures, ed. by D.J. Sellmyer, R. Skomski (Springer, Boston, 2006), p. 365

Y. Xu, Y. Sun, X. Dai, B. Liao, S. Zhou, D. Chen, Microstructure and magnetic properties of amorphous/nanocrystalline Ti50Fe50 alloys prepared by mechanical alloying. J. Mater. Res. Technol. 8(3), 2486–2493 (2019)

R. Koohkan, S. Sharafi, H. Shokrollahi, K. Janghorban, Preparation of nanocrystalline Fe-Ni powders by mechanical alloying used in soft magnetic composites. J. Magn. Magn. Mater. 320, 1089–1094 (2008)

G. Herzer, Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans. Magn. 26, 1397–1402 (1990)

H. Shokrollahi, The magnetic and structural properties of the most important alloys of iron produced by mechanical alloying. Mater. Des. 30, 3374–3387 (2009)

A.H. Bahrami, H. Ghayour, S. Sharafi, Evolution of microstructural and magnetic properties of mechanically alloyed Fe80−xNi20Six nanostructured powders. Powder Technol. 249, 7–14 (2013)

X. Wang, Q. Liu, Y. Huang, L. Xie, Q. Xu, T. Zhao, Effect of Ti content on the microstructure and corrosion resistance of CoCrFeNiTix high entropy alloys prepared by laser cladding. Materials 13(4–13), 2209 (2020)

S. Ma, J. Zhang, Wear resistant high boron cast alloy—a review. Rev. Adv. Mater. Sci. 44, 54–62 (2016)

L. Zong, N. Guo, R. Li, H. Yu, Effect of B content on microstructure and wear resistance of Fe-3Ti-4C hardfacing alloys produced by plasma-transferred arc welding. Coatings 9(2–11), 265 (2019)

C.P. Lee, Y.Y. Chen, C.Y. Hsu, J.W. Yeh, H.C. Shi, The effect of boron on the corrosion resistance of the high entropy alloys Al0.5CoCrCuFeNiBx. J. Electrochem. Soc. 154(8), C424–C430 (2007)

A.N. Faruqui, P. Manikandan, T. Sato, Y. Mitsuno, K. Hokamoto, Mechanical milling and synthesis of Mg-SiC composites using underwater shock consolidation. Met. Mater. Int. 18, 157–163 (2012)

Y.J. Liu, I.T.H. Chang, Effects of oxide phases on thermomagnetisation of mechanically alloyed amorphous Fe–(Co, Ni)–Zr–B powder. Mater. Sci. Eng. A 375–377, 1092–1096 (2004)

N.D. Phu, D.T. Ngo, L.H. Hoang, N.H. Luong, N.H. Hai, Crystallization process and magnetic properties of amorphous iron oxide nanoparticles. J. Phys. D 44(34), 345002 (2011)

Acknowledgements

This work was supported by Scientific Research Projects Coordination Unit of Zonguldak Bülent Ecevit University, Project No. 2015-73338635-01.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Panigrahi, M., Avar, B. Influence of mechanical alloying on structural, thermal, and magnetic properties of Fe50Ni10Co10Ti10B20 high entropy soft magnetic alloy. J Mater Sci: Mater Electron 32, 21124–21134 (2021). https://doi.org/10.1007/s10854-021-06612-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06612-z