Abstract

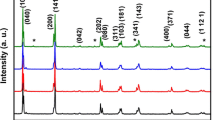

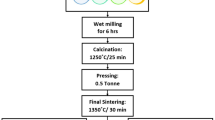

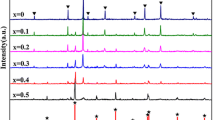

xAl2O3-(1-x)LaCrO3 (x = 0.3, 0.4, 0.5, 0.7) composite negative temperature coefficient (NTC) ceramics were prepared by microwave sintering. The effects of different atmospheres and sintering temperatures on microstructure and electrical properties of the NTC ceramics were studied. X-ray diffraction results showed the ceramics were composed of a perovskite structure LaCrO3 and lanthanum hexaaluminate solid solution as well as a separate corundum phase. The existence of Cr3+ and Cr4+, which resulted in skip conduction, was confirmed by X-ray photoelectron spectroscopy. The resistance of the ceramics sintered in air was lower than that of ceramics sintered in an N2 atmosphere. Ceramics sintered in air and N2 showed NTC characteristics starting at 40 °C and 250 °C, respectively. The ρ50 and B300/700 values of the ceramics sintered in air were in the range of 5.06 × 105–2.21 × 109 Ω·cm and 4144–6828 K, respectively. The ceramics prepared at 1400 °C with a holding time of 5 min possessed excellent microstructure and electrical properties. Compared with conventional pressureless sintering, the sintering temperature and holding time of the microwave sintering process were decreased by 6.6–12.5% and 95.8–99.0%, respectively.

Similar content being viewed by others

References

D. Houivet, J. Bernard, J.M. Haussonne, High temperature NTC ceramic resistors (ambient-1000°C). J. Eur. Cer. Soc. 24, 1237–1241 (2004). https://doi.org/10.1016/S0955-2219(03)00376-5

A. Banerjee, S.A. Akbar, A new method for fabrication of stable and reproducible yttria-based thermistors. Sens. Actuators A 87, 60–66 (2000). https://doi.org/10.1016/S0924-4247(00)00466-0

D. Katerinopoulou, P. Zalar, J. Sweelssen, G. Kiriakidis, C. Rentrop, P. Groen et al., Large-area all-printed temperature sensing surfaces using novel composite thermistor materials. Adv. Electron. Mater. 5, 1800605 (2019). https://doi.org/10.1002/aelm.201800605

A. Feteira, K. Reichmann, NTC ceramics: past present and future. Adv. Sci. Technol. 67, 124–133 (2010)

R.N. Jadhav, S.N. Mathad, V. Puri, Studies on the properties of Ni0.6Cu0.4Mn2O4 NTC ceramic due to Fe doping. Ceram. Int. 38, 5181–5188 (2012). https://doi.org/10.1016/j.ceramint.2012.03.024

F. Guan, X.J. Lin, H. Dai et al., LaMn1-xTixO3-NiMn2O4(0 ≤ x ≤ 0.7): A composite NTC ceramic with controllable electrical property and high stability. J. Eur. Ceram. Soc. 39, 2692–2696 (2019). https://doi.org/10.1016/j.jeurceramsoc.2019.03.003

K. Park, I.H. Han, Effect of partial substitution of Mg for Coin Mn1.4Ni1.2Co0.4O4 NTC thermistors on electrical stability. J. Electroceram. 17, 1079–1082 (2006). https://doi.org/10.1007/s10832-006-0465-1

R.N. Jadhav, V. Puri, Influence of copper substitution on structural, electrical and dielectric properties of Ni(1–x)CuxMn2O4 (0≤x≤1) ceramics. J. Alloys Compd. 507, 151–156 (2010). https://doi.org/10.1016/j.jallcom.2010.07.143

O. Shpotyuk, V. Balitska, I. Hadzaman et al., Sintering-modified mixed Ni-Co-Cu oxymanganospinels for NTC electroceramics. J. Alloys Compd. 509, 447–450 (2011). https://doi.org/10.1016/j.jallcom.2010.09.054

K. Park, J.K. Lee, S.J. Kim et al., The effect of Zn on the microstructure and electrical properties of Mn1.17-xNi0.93Co0.9ZnxO4 (0 ≤ x ≤ 0.075) NTC thermistors. J. Alloys Compd. 467, 310–316 (2009). https://doi.org/10.1016/j.jallcom.2007.11.105

T. Yang, Bo. Zhang et al., New high temperature NTC thermistors based on the Mg(Al1-xCrx)2O4 ceramics. J. Alloys Compd. 685, 287–293 (2016). https://doi.org/10.1016/j.jallcom.2016.05.301

Q. Ma, Q. Zhao, X. Jia et al., Preparation and characterization for LaMnO3 and 0.3LaMnO3–0.7Y2O3 high temperature bilayer structure NTC thermistors. J Mater Sci-Mater El. 30, 11005–11010 (2019). https://doi.org/10.1007/s10854-019-01441-7

H. Zhang, T. Liu, L. Zhao et al., Effect of Al2O3 addition on the microstructure and electrical properties of LaMnO3-based NTC thermistors. J. Mater. Sci. 28, 14195–14201 (2017). https://doi.org/10.1007/s10854-017-7276-9

Jinseong Park, Micro structural and electrical properties of Y0.2Al0.1Mn0.27-xFe0.16Ni0.27-x(Cr2x)Oy for NTC thermistors. Ceram. Int. 41, 6386–6390 (2015). https://doi.org/10.1016/j.ceramint.2015.01.075

F. Guan, Z.W. Dang, S.F. Huang et al., LaCr1-xFexO3 (0≤x≤0.7): A novel NTC ceramic with high stability. J. Eur. Ceram. Soc. 40, 5597–5601 (2020). https://doi.org/10.1016/j.jeurceramsoc.2020.05.081

B. Zhang, Q. Zhao, A. Chang et al., Spark plasma sintering of MgAl2O4-YCr0.5Mn0.5O3 composite NTC ceramics. J. Eur. Ceram. Soc. 34, 2989–2995 (2012). https://doi.org/10.1016/j.jeurceramsoc.2014.03.025

B. Zhang, Q. Zhao, A. Chang et al., MgAl2O4-LaCr0.5Mn0.5O3 composite ceramics for high temperature NTC thermistors. J Mater Sci-Mater El. 24, 4452–4456 (2013). https://doi.org/10.1007/s10854-013-1424-7

A. Ga, X. Yin, Q. Zhao et al., A study based on MgAl2O4-LaCrO3 composite ceramics for high temperature NTC thermistors. J. Mater Sci.-Mater. El. 30, 11117–11122 (2019). https://doi.org/10.1007/s10854-019-01454-2

Tian Yang, Bo. Zhang et al., New NTC thermistors based on LaCrO3-Mg(Al0.7Cr0.3)2O4 composite ceramics. J. Mater. Sci.-Mater. El. 28, 7558–7561 (2017). https://doi.org/10.1007/s10854-017-6445-1

Y. Cheng, S. Sun, H. Hu, Preparation of Al2O3/TiC micro-composite ceramic tool materials by microwave sintering and their microstructure and properties. Ceram. Int. 40, 16761–16766 (2014). https://doi.org/10.1016/j.ceramint.2014.08.044

D. Hong, Z. Yin, S. Yan et al., Fine grained Al2O3/SiC composite ceramic tool material prepared by two-step microwave sintering. Ceram. Int. 45, 11826–11832 (2019). https://doi.org/10.1016/j.ceramint.2019.03.061

Z. Zhu, Z. Yin, D. Hong et al., Preparation of complex-shaped Al2O3/SiCp/SiCw ceramic tool by two-step microwave sintering. Ceram. Int. 46, 27362–27372 (2020). https://doi.org/10.1016/j.ceramint.2020.07.221

C. Gindorf, L. Singheiser, K. Hilpert, Vaporisation of chromia in humid air. J Phys Chem Solids. 66, 384–387 (2005). https://doi.org/10.1016/j.jpcs.2004.06.092

M. Mori, T. Yamamoto, T. Ichikawa et al., Dense sintered conditions and sintering mechanisms for alkaline earth metal (Mg, Ca and Sr)-doped LaCrO3 perovskites under reducing atmosphere. Solid State Ion. 148, 93–101 (2002). https://doi.org/10.1016/S0167-2738(02)00109-1

A.N. Kamlo, J. Bernard, C. Lelievre et al., Synthesis and NTC properties of YCr1-xMnxO3 ceramics sintered under nitrogen atmosphere. J. Eur. Ceram. Soc. 31, 1457–1463 (2011). https://doi.org/10.1016/j.jeurceramsoc.2010.12.025

A. Feteira, Negative Temperature Coefficient Resistance (NTCR) Ceramic Thermistors: An Industrial Perspective. J. Am. Ceram. Soc. 92, 967–983 (2009). https://doi.org/10.1111/j.1551-2916.2009.02990.x

Luo Ping, Bo. Zhang et al., Characterization and electrical conductivity of La1−xSrxCrO3 NTC ceramics. J. Mater. Sci.-Mater. El. 28, 9265–9271 (2017). https://doi.org/10.1007/s10854-017-6662-7

O. Polat, M. Coskun, F.M. Coskun et al., Electrical characterization of Ir doped rare-earth orthoferrite YbFeO3. J. Alloys Compd. 787, 1212–1224 (2019). https://doi.org/10.1016/j.jallcom.2019.02.141

J.L. Ye, C.C. Wang, W. Ni et al., Dielectric properties of ErFeO3 ceramics over a broad temperature range. J. Alloys Compd. 617, 850–854 (2014). https://doi.org/10.1016/j.jallcom.2014.08.026

B. Zhang, Q. Zhao, A. Chang et al., Spark Plasma Sintering of MgAl2O4-LaCr0.5Mn0.5O3 Composite Thermistor Ceramics and a Comparison Investigation with Conventional Sintering. J. Alloys Compd. 675, 381–386 (2016). https://doi.org/10.1016/j.jallcom.2016.03.139

A. Banerjee, S.A. Akbar, A New Method for Fabrication of Stable and Reproducible Yttria-Based Thermistors. Sens. Actuators, A 87, 60–66 (2000). https://doi.org/10.1016/S0924-4247(00)00466-0

Acknowledgements

The work is supported by National Natural Science Foundation of China (51875291), Excellent Youth Fund of Jiangsu Province (BK20190070), Jiangsu Provincial Six Talent Peaks Project (GDZB-016), and the Fundamental Research Funds for the Central Universities (30920032206).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hao, X., Yin, Z., Hong, D. et al. Microstructure and electrical properties of xAl2O3-(1-x) LaCrO3 composite NTC ceramics prepared by microwave sintering. J Mater Sci: Mater Electron 32, 19412–19423 (2021). https://doi.org/10.1007/s10854-021-06458-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06458-5