Abstract

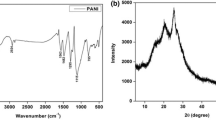

In this work, we prepared the epoxy-based adhesives with a binary filler system, which was composed of organosilicon modified hexagonal BN (h-BN) and α-Al2O3. H-BN platelets and α-Al2O3 nanoparticles were decorated by aminopropyltrimethoxysilane (APTMS) and glycidylpropyltrimethoxysilane (GPTMS), respectively, to form covalent links to the filler/polymer matrix interface. The surface chemical composition was investigated by Fourrier transform infrared spectroscopy (FTIR) and thermogravimetry analysis (TGA), which demonstrated that the modifiers were successfully grafted onto the surface of fillers. This modification has been confirmed beneficial to thermal conductivity so that the thermal conductivity of adhesives incorporated with modified binary fillers could reach 0.85 w/m k, which is 10% more than specimen filled with unmodified fillers, because covalent links strengthened the interface and prohibited heat diffusion. Modified Hashin–Shtrikman model was utilized to analyze thermal resistance of the binary filler system, indicating that adhesives filled with modified fillers displayed lower thermal resistance. The enhancement of interface also brought about some other positive effect, especially in the decreasing of dielectric constant (< 4.3 at 1000 Hz) and the low values of dielectric loss tangent (10–3) and high electronic resistance (> 1014). Furthermore, the mechanical strength is significantly improved when the modified binary fillers were used.

Similar content being viewed by others

References

Y. Yao, X. Zeng, R. Sun et al., ACS Appl. Mater. Interfaces 8, 15645 (2016)

X. Zhao, L. Song, X. Zhu et al., Composites A 113, 287 (2018)

H. Wu, M.R. Kessler, ACS Appl. Mater. Interfaces 7, 5915 (2015)

W. Lei, V.N. Mochalin, D. Liu et al., Nat. Commun. 6, 8849 (2015)

C. Zhang, Y. He, Y. Zhan et al., Polym. Adv. Technol. 28, 214 (2017)

D.S. Muratov, A.A. Stepashkin, S.M. Anshin et al., J. Alloys Compd. 735, 1200 (2018)

J. Fu, L. Shi, D. Zhang et al., Polym. Eng. Sci. 50, 1809 (2010)

H.J. Ahn, Y.J. Eoh, S.D. Park et al., Thermochim. Acta 590, 138 (2014)

S. Ryu, T. Oh, J. Kim, RSC Adv. 8, 22846 (2018)

T. Morishita, N. Takahashi, RSC Adv. 7, 36450 (2017)

H. Hirano, J. Kadota, T. Yamashita, et al. World Acad. Sci. Eng. Technol. (2012)

I. Jang, K.-H. Shin, I. Yang et al., Colloids Surf., A 518, 64 (2017)

D.S. Muratov, D.V. Kuznetsov, I.A. Il’inykh et al., Compos. Sci. Technol. 111, 40 (2015)

C. Kizilkaya, Y. Mülazim, M. Vezir Kahraman et al., J. Appl. Polym. Sci. 124, 706 (2012)

S. Ryu, K. Kim, J. Kim. Polym. Compos. 39, 1692 (2018)

S. Ryu, K. Kim, J. Kim. Polym. Adv. Technol. 28, 1489 (2017)

L. Fang, C. Wu, R. Qian et al., RSC Adv. 4, 21010–21017 (2014)

Y. Guo, Z. Lyu, X. Yang et al., Composites B 164, 732 (2019)

S.L. Chung, J.S. Lin, Molecules 21, 670 (2016)

K. Kim, M. Kim, Y. Hwang et al., Ceram. Int. 40, 2047 (2014)

M. Derradji, X. Song, A.Q. Dayo et al., Appl. Therm. Eng. 115, 630 (2017)

C. Yu, J. Zhang, W. Tian et al., RSC Adv. 8, 21948 (2018)

W. Bian, T. Yao, M. Chen et al., Compos. Sci. Technol. 168, 420 (2018)

Y.-K. Kim, J.-Y. Chung, J.-G. Lee et al., Composites A 98, 184 (2017)

Z. Zheng, M. Cox, B. Li, J. Mater. Sci. 53, 66 (2018)

A. Ares, A. Lasagabaster, M.J. Abad et al., J. Compos. Mater. 48, 3141 (2013)

F. Yuan, W. Jiao, F. Yang et al., RSC Adv. 7, 43380 (2017)

A. Permal, M. Devarajan, H.L. Hung et al., J. Mater. Eng. Perform. 27, 1296 (2018)

H. Chen, V.V. Ginzburg, J. Yang et al., Prog. Polym. Sci. 59, 41 (2016)

I.-L. Ngo, S.V. PrabhakarVattikuti, C. Byon, Int. J. Heat Mass Transf. 114, 727 (2017)

I.L. Ngo, C. Byon, B.J. Lee, Int. J. Heat Mass Transf. 126, 474 (2018)

C. Zhang, G.C. Stevens, Dielectric properties of boron nitride filled epoxy composites, in Conference on Electrical Insulation and Dielectric Phenomena (2006), p. 19

J. Gu, X. Meng, Y. Tang et al., Composites A 92, 27 (2017)

Z. Dang, M. Zheng, 7-multiphase/multicomponent dielectric polymer materials with high permittivity and high breakdown strength, in Dielectric polymer materials for high-density energy storage, ed. by Z. Dang (William Andrew Publishing, Oxford, 2018), pp. 247–287

D. Yang, M. Tian, D. Li et al., J. Mater. Chem. A 1, 12276–12284 (2013)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 51603015), Science Program of Beijing Municipal Education Commission (KM202010017002) and Key Laboratory of Photochemical Conversion and Optoelectronic Materials, Technical Institute of Physics and Chemistry, Chinese Academy of Sciences (PCOM201918).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Gao, D., Yu, L., Li, M. et al. Thermal conductive epoxy adhesive with binary filler system of surface modified hexagonal boron nitride and α-aluminum oxide. J Mater Sci: Mater Electron 31, 14681–14690 (2020). https://doi.org/10.1007/s10854-020-04031-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04031-0