Abstract

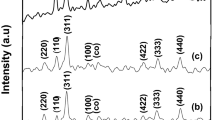

Cobalt oxide, hematite, and Co3O4/α-Fe2O3 nanopowders (NPs) have been successfully synthesized by hydrothermal technique. Co3O4 is well crystallized in spinel cubic structure, while the hematite possesses the rhombohedral structure. The mixture of these two materials gave spinel cobalt ferrite. The average crystallite size calculated from Scherer’s equation was 49 and 34 nm for Fe2O3 and Co3O4, respectively, while it is decreased to 19 nm for the Co3O4/α-Fe2O3 NCs. This reduction is probably attributed to the high enthalpy of formation of the mixture in comparison with the two other materials. Scanning electron microscopy and transmission electron microscopy photographs indicate that the Co3O4/α-Fe2O3 NPs are composed of homogenous spherical grains and small agglomerated crystallites. All the prepared samples exhibited a superparamagnetic behavior with very low remanence and coercivity. The origin of the superparamagnetism may be related to the uncompensated surface spin and tiny size of the nanoparticles. The magnetization at saturation of the mixture is strongly enhanced to 45.7 emu/g after it was around 2 emu/g for both Co3O4 and hematite. BET analysis showed that the composite had a high surface area (around 60 m2/g) compared to Co3O4 and hematite. This makes Co3O4/α-Fe2O3 a good candidate for several applications such as drag delivery, supercapacitors, and magnetic resonance imaging.

Similar content being viewed by others

References

M.Y. Nassar, Mater. Lett. 94, 112–115 (2013)

J. Gajendiran, V. Rajendran, Mater. Sci. Semicond. Process. 17, 59–62 (2014)

R. Tummala, R.K. Guduru, P.S. Mohanty, J. Power Sources 209, 44–51 (2012)

F. Wang, J. Liu, X. Wang, J. Kong, S. Qiu, G. Lu, C. He, Mater. Lett. 76, 159–161 (2012)

L. Xu, Y. Zhou, Z. Wu, G. Zheng, J. He, Y. Zhou, J. Phys. Chem. Solids 106, 29–36 (2017)

Y. Liu, L. Sun, J. Wu, T. Fang, R. Cai, A. Wei, Mater. Sci. Eng. B 194, 9–13 (2015)

D. Malwal, P. Gopinath, J. Hazard. Mater. 321, 611–621 (2017)

A. Lavín, R. Sivasamy, E. Mosquera, M.J. Morel, Surf. Interfaces 17, 100367 (2019)

W. Wang, L. Xu, R. Zhang, J. Xu, F. Xian, J. Su, F. Yan, Chem. Phys. Lett. 721, 57–61 (2019)

F.S. Hashim, A.F. Alkaim, S.M. Mahdi, A.H. Omran Alkhayatt, Compos. Commun. 16, 111–116 (2019)

S.H. Güler, Ö. Güler, E. Evin, S. Islak, Optik 127, 3187–3191 (2016)

E. Alp, H. Eşgin, M. Kürşat Kazmanlı, A. Genç, Ceram. Int. 45, 9174–9178 (2019)

J.A. Melero, G. Calleja, F. Martínez, R. Molina, Catal. Commun. 7, 478–483 (2006)

M.M. Natile, A. Glisenti, J. Mol. Catal. A 217, 175–184 (2004)

A. Din, K. Akhtar, K.S. Karimov, N. Fatima, A.M. Asiri, M.I. Khan, S.B. Khan, J. Mol. Liq. 237, 266–271 (2017)

B. Yang, J. Liu, H. Qin, Q. Liu, X. Jing, H. Zhang, R. Li, G. Huang, J. Wang, J. Alloys Compd. 727, 52–62 (2017)

Y. Xiang, Y. Zhu, J. Lu, C. Zhu, M. Zhu, Q. Xie, T. Chen, Solid State Sci. 93, 79–86 (2019)

Q.Q. Xiong, X.H. Xia, J.P. Tu, J. Chen, Y.Q. Zhang, D. Zhou, C.D. Gu, X.L. Wang, J. Power Sources 240, 344–350 (2013)

I.C.B. Alves, J.R.N. Santos, D.S.S. Viégas, E.P. Marques, C.A. Lacerda, L. Zhang, J. Zhang, A.L.B. Marques, J. Braz. Chem. Soc. 30, 2681–2690 (2019)

A. Abdelkader, H. Daly, Y. Saih, K. Morgan, M.A. Mohamed, S.A. Halawy, C. Hardacre, Int. J. Hydrogen Energy 38, 8263–8275 (2013)

A. Mirzaei, S. Park, G.J. Sun, H. Kheel, C. Lee, J. Korean Phys. Soc. 69, 373–380 (2016)

H. Jin, X. Gu, B. Hong, L. Lin, C. Wang, D. Jin, X. Peng, X. Wang, H. Ge, J. Phys. Chem. C 116, 13374 (2012)

M.F. Valan, A. Manikandan, S. Arul Antony, J. Nanosci. Nanotechnol. 14, 1–7 (2014)

V. Raman, S. Suresh, P.A. Savarimuthu, T. Raman, A.M. Tsatsakis, K.S. Golokhvast, V.K. Vadivel, Exp. Ther. Med. 11, 553–560 (2016)

B.D. Cullity, Elements of X-ray Diffraction (Addison-Wesley, Reading, 1978), p. 102

A. Goldman, Modern Ferrite Technology (Van Nostrand Reinhold, New York, 1990)

P. Scherrer, Nachr. Ges. Wiss. Göttingen 26, 98–100 (1918)

J.I. Langford, A.J.C. Wilson, J. Appl. Cryst. 11, 102–113 (1978)

Uvarov and Popov, Mater. Charact. 85, 111 (2013)

G.K. Williamson, W.H. Hall, Acta Metall. 1, 22 (1953)

Q.Z. Zeng, S.Y. Ma, W.X. Jin, H.M. Yang, H. Chen, Q. Ge, L. Ma, J. Alloys Compd. 705, 427–437 (2017)

C.M. Hung, N.D. Hoa, N.V. Duy, N.V. Toan, D.T. Thanh Le, N.V. Hieu, J. Sci. Adv. Mater. Dev. 1, 45–50 (2016)

M.A. Chougule, S. Sen, V.B. Patil, Ceram. Int. 38, 2685–2692 (2012)

M. Salavati-Niasari, A. Khansari, C. R. Chim. 17, 352–358 (2014)

S. Farhadi, M. Javanmrad, G. Nadri, Acta Chim. Slov. 63, 335–343 (2016)

J. Ma, S. Zhang, W. Liu, Y. Zhao, J. Alloys Compd. 490, 647–651 (2010)

W.L. Roth, J. Phys. Chem. Solid 25, 1 (1964)

G. Anandha-Babu, G. Ravi, Y. Hayakawa, M. Kumaresavangi, J. Magn. Magn. Mater. 375, 184–193 (2015)

G. Li, Y. Jiang, K. Huang, P. Ding, J. Chen, J. Alloys Compd. 466, 451–456 (2008)

J. Zhi, Y. Wang, Y. Lu, J. Ma, G. Luo, Reat. Funct. Polym. 66, 1552–1558 (2006)

Acknowledgments

The authors, therefore, acknowledge with thanks DSR technical and financial support.

Funding

This work was funded by the Deanship of Scientific Research (DSR), King Abdulaziz University, Jeddah, under Grant No. 130-166-D1440.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hjiri, M., Aida, M.S. Co3O4/α-Fe2O3 nanocomposites (NCs): synthesis and characterization. J Mater Sci: Mater Electron 31, 5591–5598 (2020). https://doi.org/10.1007/s10854-020-03125-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03125-z