Abstract

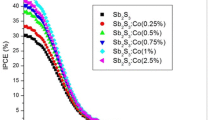

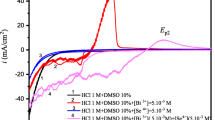

TiO2 is a kind of semiconductor with a wide bandgap. Because of its wide bandgap, it has a poor response to visible light. Using Bi2S3 to sensitize TiO2 can not only broaden the optical absorption range but also reduce carrier recombination. Bi(NO3)3 is often used as a Bi source in the preparation of Bi2S3. There are few reports about Bi2S3 preparation using BiCl3 and Bi(Ac)3. In the present work, the effect of Bi sources (Bi(NO3)3, BiCl3, and Bi(CH3COOH)3) on the TiO2/Bi2S3 morphology, structure, and photoelectric performance has been studied. Afterward, the physicochemical properties of the TiO2/Bi2S3 composites were studied through FESEM and XRD measurements. The photoelectrochemical performance was determined by UV–Visible spectrophotometer and electrochemical impedance spectroscopy. The morphology and distribution of Bi2S3 obtained from different Bi sources are quite different. The photoelectric properties of TiO2/Bi2S3 composites are closely related to the morphology and distribution of Bi2S3. Whatever Bi sources were used, the photoelectric properties of the composites showed increase first and then decrease with the increase of reaction time. When the reaction time was 6 h, the maximum current density was obtained. The photocurrent density of TiO2/Bi2S3 (Cl) is the largest. The maximum photocurrent density of TiO2/Bi2S3 (Cl) is 0.10 mA/cm2. The maximum photocurrent density of TiO2/Bi2S3 (Ac) and TiO2/Bi2S3 (N) is 0.01 mA/cm2 and 0.08 mA/cm2, respectively. The BiCl3 as a Bi source is beneficial to the improvement of photoelectric properties of the TiO2/Bi2S3 composites.

Similar content being viewed by others

References

Z. Du, H. Zhang, H. Biao, X. Zhong, J. Mater. Chem. A 32, 13033–13040 (2014). https://doi.org/10.1039/C4TA02291B)

M. Seol, H. Kim, Y. Tak, K. Yong, Chem. Commun. 46, 5521–5523 (2010). https://doi.org/10.1039/C0CC00542H

Z. Zhu, J. Qiu, K. Yan, S. Yang, A.C.S. Appl, Mater. Interfaces 5, 4000–4005 (2013). https://doi.org/10.1021/am400235g

L. Li, T. Zhai, Y. Bando, D. Golberg, Nano Energy 1, 91–106 (2012). https://doi.org/10.1016/j.nanoen.2011.10.005

M.A. Hossain, J.R. Jennings, Z.Y. Koh, Q. Wang, ACS Nano 5, 3172–3181 (2011). https://doi.org/10.1021/nn200315b

Y. Zhang, W. Xu, X. Xu, J. Cai, W. Yang, X. Fang, J. Phys. Chem. Lett. 10, 836–841 (2019). https://doi.org/10.1021/acs.jpclett.9b00154

S. Tuckute, S. Varnagiris, M. Urbonavicius, M. Lelis, S. Sakalauskaite, Appl. Surf. Sci. 489, 576–583 (2019). https://doi.org/10.1016/j.apsusc.2019.05.341)

J. Singh, S.A. Khan, J. Shah, R.K. Kotnala, S. Mohapatra, Appl. Surf. Sci. 422, 953–961 (2017). https://doi.org/10.1016/j.apsusc.2017.06.068)

C.Y. Huang, R.T. Guo, W.G. Pan, J.Y. Tang, W.G. Zhou, X.Y. Liu, H. Qin, P.Y. Jia, Appl. Surf. Sci. 464, 534–543 (2019). https://doi.org/10.1016/j.apsusc.2018.09.114

J.C. Lee, A.I. Gopalan, G. Sai-Anand, L.P. Lee, W.J. Kim, Catalysts 9, 170 (2019). https://doi.org/10.3390/catal19020170

A.I. Gopalan, S. Komathi, N. Muthuchamy, K.P. Lee, M.J. Whitcombe, L. Dhana, G. Sai-Anand, Prog. Polym. Sci. 88, 11–29 (2019). https://doi.org/10.1016/j.progpolymsci.2018.08.001

Y.Y. Xu, M. Zhang, J.G. Lv, M.C. Zhang, X.S. Jiang, X.P. Song, G. He, Z.Q. Sun, Appl. Surf. Sci. 317, 1035–1040 (2014). https://doi.org/10.1016/j.apsusc.2014.08.173

Y. Zhang, W. Zhang, T.F. Xie, D.J. Wang, X.M. Song, Mater. Res. Bull. 48, 3242–3246 (2013). https://doi.org/10.1016/j.materrsebull.2013.04.088

A. Tubtimtae, K.L. Wu, H.Y. Tung, M.W. Lee, G.J. Wang, Electrochem. Commun. 12, 1158–1160 (2010). https://doi.org/10.1016/j.elecom.2010.06.006

H.K. Jun, M.A. Careem, A.K. Arof, Renew. Sust. Energy Rev. 22, 148–167 (2013). https://doi.org/10.1016/j.rser.2013.01.030)

I. Barceló, T.L. Villarreal, R. Gómez, J. Photochem. Photobiol. A 220, 47–53 (2011). https://doi.org/10.1016/j.photochem.2011.03.016

W. Liu, H. Ji, J. Wang, X. Zheng, J. Lai, J. Ji, T. Li, Y. Ma, H. Li, S. Zhao, Z. Jin, J. Mater. Sci. Mater. Electron. 26, 1474–1484 (2015). https://doi.org/10.1007/s10854-014-2564-0

Q. Wang, R. Jin, C. Yin, M. Wang, J. Wang, S. Gao, Sep. Purif. Technol. 172, 303–309 (2017). https://doi.org/10.1016/j.seppur.2016.08.028

Q. Wang, Z. Liu, R. Jin, Y. Wang, S. Gao, Sep. Purif. Technol. 210, 798–803 (2019). https://doi.org/10.1016/j.seppur.2018.08.050

Z.C. Guan, X. Wang, P. Jin, Y.Y. Tang, H.P. Wang, G.L. Song, R.G. Du, Corros. Sci. 143, 31–38 (2018). https://doi.org/10.1016/j.corsci.2018.07.037

S. Kumar, S. Sharma, S. Sood, A. Umar, S.K. Kansal, Ceram. Int. 42, 17551–17557 (2016). https://doi.org/10.1016/j.ceramint.2016.08.068

J. Li, L. Jin, L. Fang, M. Zhang, Y. Wang, X. Jiang, J. Lv, G. He, Z. Sun, Appl. Surf. Sci. 456, 694–700 (2018). https://doi.org/10.1016/j.apsusc.2018.06.164

X. Li, X. Han, D. Zhu, Y. Chen, L. Li, Z. Ma, Y. Gu, F. Ren, J. Huang, Opt. Mater. 91, 101–107 (2019). https://doi.org/10.1016/j.optmat.2019.03.015

X. Li, X. Han, D. Zhu, Y. Chen, L. Li, F. Ren, J. Huang, Mater. Res. Express 6, 055910 (2019). https://doi.org/10.1088/2053-1591/ab044e

R. Zhou, Q. Zhang, J. Tian, D. Myers, M. Yin, G. Cao, J. Phys. Chem. C 117, 26948–26956 (2013). https://doi.org/10.1021/jp410615b

D. Zhu, X. Li, Y. Chen, Y. Deng, D. Chen, Y. Wang, F. Ren, Mater. Res. Express 6, 095026 (2019). https://doi.org/10.1088/2053-1591/ab2de7

Y. Deng, Z. Ma, F. Ren, G. Wang, A.A. Volinsky, Chem. Phys. Lett. 724, 42–49 (2019). https://doi.org/10.1016/j.cplett.2019.03.054

Y. Bessekhouad, D. Robert, J.V. Weber, J. Photoch. Photobio. A. 163, 569–580 (2004). https://doi.org/10.1016/j.jphotochem.2004.02.006

Funding

This work was supported by the China Postdoctoral Science Foundation [No. 2018M632771]; the Henan International Science and Technology Cooperation Project of China (No. 152102410035); and the University Key Research Project of the Henan Province (No. 15A430023).

Author information

Authors and Affiliations

Contributions

Conceptualization, XL; Data curation, XL and ML; Funding acquisition, XL; Investigation, ML, DZ, DC, MY, and MZ; Project administration, XL; Writing—original draft, DZ.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, X., Liu, M., Zhu, D. et al. Influence of Bi sources on TiO2/Bi2S3 composite films prepared by hydrothermal method. J Mater Sci: Mater Electron 31, 4662–4671 (2020). https://doi.org/10.1007/s10854-020-03018-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03018-1