Abstract

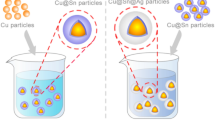

This paper presents a novel die attach material based on Cu@Sn@Ag particles, in which the outermost Ag layer prevents the oxidation of the Sn layer and expedites the consumption of the low-melting point Sn phase. The die attach material can be reflowed at 250 °C for 15 min under a pressure of 3 MPa in the atmosphere, subsequently, the bondline can sustain a much higher temperature up to 480 °C. The results show that the Sn phase was totally transformed into Cu3Sn and Ag3Sn intermetallic compounds (IMCs) after reflow. Moreover, the Cu particles were evenly distributed in the Cu3Sn and Ag3Sn IMCs. After Cu@Sn@Ag particles were heated at 250 °C for 6 h, the average mass increased only by 2.8%, which indicates that the oxidation resistance property of Cu@Sn@Ag particles is excellent. The average electrical resistivity of the bondline was 4.6 µΩ cm, and the thermal conductivities were 159.97 W m−1 K−1, 142.71 W m−1 K−1, 137.28 W m−1 K−1 at 30 °C, 150 °C, 300 °C, respectively. The average shear strengths of the bondline were 25.8 MPa and 19.7 MPa at 30 °C and 400 °C, respectively. The coefficient of thermal expansion of the bondline was measured to be 15.77 × 10–6/°C. This novel paste shows great potential in die attachment in power device packaging.

Similar content being viewed by others

References

K Ma M Liserre F Blaabjerg 2015 Thermal loading and lifetime estimation for power device considering mission profiles in wind Power converter IEEE Trans. Power Electron. 302 590 602

L Coppola D Huff F Wang 2017 Survey on high -temperature packaging materials for SiC-based power electronics modules IEEE Power Electron. Spec. Conf. 38 2234 2240

A Drevin-Bazin F Lacroix JF Barbot 2014 2014, SiC die attach for high-temperature applications J. Electron. Mater. 43 695 701

Y Zhong R An C Wang 2015 Low temperature sintering Cu6Sn5 nanoparticles for superplastic and super-uniform high temperature circuit interconnections Small 11 4097 4103

Y Mikamura K Hiratsuka T Tsuno 2015 Novel designed SiC devices for high power and high efficiency systems IEEE Trans. Electron. Dev. 62 382 389

HS Chin KY Cheong AB Ismail 2010 A review on die attach materials for SiC-based high-temperature power devices Metal. Mater. Trans. B 41 824 832

J Li X Li L Wang 2018 A novel multiscale silver paste for die bonding on bare copper by low-temperature pressure-free sintering in air Mater. Des. 140 64 72

C Chen J Yeom C Choe 2019 Necking growth and mechanical properties of sintered Ag particles with different shaps under air and N2 atmosphere J. Mater Sci. 54 13344 13357

Z Zhang C Chen Y Yang 2019 Low-temperature and pressureless sinter joining of Cu with micron/submicron Ag particle paste in air J. Alloys Compd. 780 435 442

A Albrecht A Rivadeyra A Abdellah 2017 Inkjet printing and photonic sintering of silver and copper oxide nanoparticles for ultra-low-cost conductive patterns J. Mater. Chem. C 4 3546 3554

SA Paknejad SH Mannan 2017 Review of silver nanoparticle based die attach materials for high power/temperature applications Microelectron. Reliab. 70 1 11

JF Li PA Agyakwa CM Johnson 2011 Interfacial reaction in Cu/Sn/Cu system during the transient liquid phase soldering process Acta Mater. 59 1198 1211

JF Li PA Agyakwa CM Johnson 2014 Suitable thicknesses of base metal and interlayer, and evolution of phases for Ag/Sn/Ag transient liquid-phase joints used for power die attachment J. Electron. Mater. 43 983 995

J Liu H Zhao Z Li 2018 Microstructure evolution, grain morphology variation and mechanical property change of Cu-Sn intermetallic joints subjected to high-temperature aging Mater. Charact. 135 238 244

H Chen T Hu M Li 2017 Cu@Sn core–shell structure powder preform for high-temperature applications based on transient liquid phase bonding IEEE Trans. Power Electron. 32 441 451

T Hu H Chen M Li 2017 Microstructure evolution and thermostability of bondline based on Cu@Sn core-shell structured microparticles under high-temperature conditions Mater. Des. 131 196 203

X Liu S He H Nishikawa 2017 Low temperature solid-state bonding using Sn-Coated Cu particles for high temperature die attach J. Alloys Compd. 695 2165 2172

X Liu S He H Nishikawa 2016 Thermally stable Cu3Sn/Cu composite joint for high-temperature power device Scripta Mater. 110 101 104

X Deng N Chawla KK Chawla 2004 Deformation behavior of (Cu, Ag)-Sn intermetallics by nanoindentation Acta Mater. 52 4291 4303

X Deng M Koopman N Chawla 2004 Young’s modulus of (Cu, Ag)–Sn intermetallics measured by nanoindentation Mater. Sci. Eng. A 364 240 243

KN Tu 1973 Interdiffusion and reaction in bimetallic Cu-Sn thin film Acta Metal. 21 347

H Okamoto 2000 Desk Handbook Phase Diagrams for Binary Alloys ASM International Ohio

Y Jiang T Liu H Ru 2019 Oxidation and ablation protection of double layer HfB2-SiC-Si/SiC-Si coating for graphite materials J. Alloys Compd. 782 761 771

Y Jiang Q Ren H Ru 2019 Oxidation protection of graphite materials by single-phase ultra-high temperature boride modified monolayer Si-SiC coating Ceram. Int. 45 539 549

X Li J Feng Y Jiang 2019 Anti-oxidation performance of carbon aerogel composites with SiCO ceramic inner coating Ceram. Int. 45 9704 9711

F Yu C Hang H Chen 2019 Fabrication of high-temperature resistant bondline based on multilayer core-shell hybrid microspere for power devices J. Mater. Sci. Mater. Electron. 30 4 3596 3600

X Quang LT Jose TN Vinh 2019 Understanging the effects of stress on the coefficient of the thermal expansion Int. J. Eng. Sci. 141 83 94

R Zare H Sharifi MR Saeri 2019 Investigating the effect of SiC particles on the physical and thermal properties of Al6061/SiCp composite J. Alloys Compd. 801 520 528

SH Kee WJ Kim JP Jung 2019 Copper-sillicon carbide composite for inhibiting the extrusion of through silicon via (TSV) Microelectron. Eng. 214 5 14

WJ Parker RJ Jenkins CP Butler 1961 Flash method of determining thermal diffusivity, heat capacity, and thermal conductivity J. Appl. Phys. 32 9 1679 1684

RR Chromik RP Vinci SL Allen 2003 Nanoindentation measurements on Cu–Sn and Ag–Sn intermetallics formed in Pb-free solder joints J. Mater. Res. 18 9 2251 2261

P Yang Y Lai S Jian 2007 Mechanical properties of Cu6Sn5, Cu3Sn, and Ni3Sn4 intermetallic compounds measured by nanoindentation Int. Conf. Electron. Packag. Technol. https://doi.org/10.1109/ICEPT.2007.4441421

FM Smits 1958 Measurement of sheet resistivities with the four-point probe bell system Tech. J. 37 3 711 718

Ackonwledgements

This work is financially supported by the Opening Project of Science and Technology on Reliability Physics and Application of Electronic Component Laboratory (ZHD201801).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, J., Wang, K., Yu, F. et al. A paste based on Cu@Sn@Ag particles for die attachment under ambient atmosphere in power device packaging. J Mater Sci: Mater Electron 31, 1808–1816 (2020). https://doi.org/10.1007/s10854-019-02697-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02697-9