Abstract

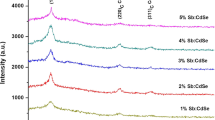

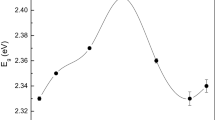

CdS films were deposited by CBD on a glass substrate by using CdI2 as a Cd+ source, thiourea as an S− source and NH4OH as the complexing agent. The effect of slow and rapid cooling on the films after thermal annealing was investigated in the present study. X-ray diffraction and Raman spectra of the films suggest that thermal annealing followed by slow cooling gives CdS with enhanced crystallinity and reduced strain and dislocation density as compared to the films where they were cooled rapidly after thermal annealing. The results were supported by scanning electron microscopy and UV–Vis absorption spectroscopy. Hall Effect measurement shows the lowest resistivity and highest mobility obtained in the case of a slowly cooled sample as compared to the rapidly cooled sample. Carrier concentration in the range of about 1011 (cm−3) was found, and all the samples of CdS were of n-type conductivity.

Similar content being viewed by others

References

J. Britt, C. Ferekides, Appl. Phys. Lett. 62, 2851–2852 (1993)

D.J. Coyle, H.A. Blaydes, R.S. Northey, J.E. Pickett, K.R. Nagarkar, R. Zhao, J.O. Gardner, Prog. Photovolt. 21(2), 173–186 (2013). https://doi.org/10.1002/pip

W.J. Jeong, S.K. Kim, G.C. Park, Thin Solid Films 506–507, 180–183 (2006). https://doi.org/10.1016/j.tsf.2005.08.213

T. Slimani, E. Bachir, F. Cherkaoui, E. Moursli, Energy Proced. 84, 127–133 (2015). https://doi.org/10.1016/j.egypro.2015.12.305

H. Zhan, J.K. Li, Y.F. Cheng, Optik 126, 1411–1414 (2015). https://doi.org/10.1016/j.ijleo.2014.07.119

U. Pal, R. Silva-González, G. Martínez-Montes, M. Gracia-Jiménez, M.A. Vidal, S. Torres, Thin Solid Films 305, 345–350 (1997). https://doi.org/10.1016/S0040-6090(97)00124-7

C.T. Tsai, D.S. Chuu, G.L. Chen, S.L. Yang, J. Appl. Phys. 79, 9105–9109 (1996). https://doi.org/10.1063/1.362645

J. Hiie, T. Dedova, V. Valdna, K. Muska, Thin Solid Films 511, 443–447 (2006)

B.R. Sankapal, R.S. Mane, C.D. Lokhande, Mater. Res. Bull. 35, 177–184 (2000). https://doi.org/10.1016/S0025-5408(00)00210-5

W. Yang, Z. Wu, Z. Lu, X. Yang, L. Song, Microelectron. Eng. 83, 1971–1974 (2006). https://doi.org/10.1016/j.mee.2006.02.002

Z. Rizwan, A. Zakaria, M.S.M. Ghazali, A. Jafari, F. Ud Din, R. Zamiri, Int. J. Mol. Sci. 12, 1293–1305 (2011). https://doi.org/10.3390/ijms12021293

J.R. Mann, N. Vora, I.L. Repins, Sol. Energy Mater. Sol. Cells 94, 333–337 (2010). https://doi.org/10.1016/j.solmat.2009.10.009

A.S.R. Chesman, N.W. Duffy, A. Martucci, L. De Oliveira Tozi, T.B. Singh, J.J. Jasieniak, J. Mater. Chem. C 2, 3247–3253 (2014). https://doi.org/10.1039/c3tc32189d

H. Jun-Feng, F. Gan-Hua, V. Krishnakumar, L. Cheng, W. Jaegermann, J. Mater. Sci.: Mater. Electron. 24, 2695–2700 (2013). https://doi.org/10.1007/s10854-013-1157-7

N. Maticiuc, M. Kukk, N. Spalatu, T. Potlog, M. Krunks, V. Valdna, J. Hiie, Energy Proced. 44, 77–84 (2014). https://doi.org/10.1016/j.egypro.2013.12.012

R.R. Prabhu, M.A. Khadar, Bull. Mater. Sci. 31(3), 511–515 (2008)

V.P. Nandakumar, C. Vijayan, M. Rajalakshmi, A.K. Arora, Y.V.G.S. Murti, Physica E 11, 377–383 (2001). https://doi.org/10.1016/S1386-9477(01)00157-6

H. Metin, R. Esen, J. Cryst. Growth 258, 141–148 (2003). https://doi.org/10.1016/S0022-0248(03)01518-5

F. Liu, Y. Lai, J. Liu, B. Wang, S. Kuang, Z. Zhang, J. Li, Y. Liu, J. Alloys Compd. 493, 305–308 (2010). https://doi.org/10.1016/j.jallcom.2009.12.088

H. Khallaf, I.O. Oladeji, G. Chai, L. Chow, Thin Solid Films 516, 7306–7312 (2008). https://doi.org/10.1016/j.tsf.2008.01.004

A. Abdolahzadeh Ziabari, F.E. Ghodsi, Sol. Energy Mater. Sol. Cells 105, 249–262 (2012). https://doi.org/10.1016/j.solmat.2012.05.014

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Shaikh, R.A.G., More, S.A., Bisen, G.G. et al. Effect of thermal annealing and cooling rate on CBD grown CdS thin films. J Mater Sci: Mater Electron 30, 20354–20359 (2019). https://doi.org/10.1007/s10854-019-02238-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02238-4