Abstract

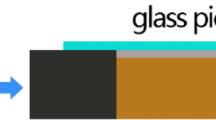

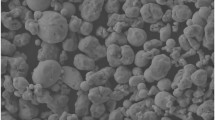

Transient liquid phase (TLP) bonding was applied to prepare Cu/In-Sn-xAg/Cu (x = 20, 30, 40, 50, 60, 70 wt%) solder joints, and the effect of Ag particle content on joint microstructure, shear property and growth mechanism of intermetallic compound (IMC) was studied. The results indicated that the microstructure of solder joint consists of interfacial diffusion reaction zone and particle in situ reaction zone. The IMC in interfacial diffusion reaction zone is Cu3(In, Sn) phase and the IMCs in in situ reaction zone is composed of In-rich phase + Ag particle + ζ-Ag3In + Ag3(In, Sn). With the increasing Ag particle content, the thickness of IMC layer in diffusion reaction zone is decreased, the total amount of In-rich phase and Ag3(In, Sn) phase in in situ reaction zone is decreased, the quantity of Ag particles and ζ-Ag3In phase is grew. The AgIn2 phase is a stable IMC formed as a preferential reaction because it requires less Gibbs free energy than Sn-Ag phase, and it is transformed to ζ-Ag3In phase with increasing bonding time to 10 min. The void ratio of solder joints is decreased firstly and then increased with increasing Ag content. The shear strength of the joint is increased firstly and then decreased with increasing Ag particle content, and the maximum shear strength 22.2 MPa is obtained by Cu/In-Sn-50Ag/Cu solder joints. The shear fracture mechanism of solder joints is changed from ductile–brittle mixed fracture to brittle fracture.

Similar content being viewed by others

References

D.H. Jung, A. Sharm, J.P. Jung, J. Mater. Sci. 53, 47 (2017)

S. Liu, S.B. Xue, P. Xue, D.X. Luo, J. Mater. Sci. 26, 4389 (2015)

Y. Du, C.T. Li, B. Huang, Solder Surf. Mt. Technol. 27, 7 (2015)

H. Chen, IEEE Trans. Power Electron. 32, 441 (2016)

G.O. Cook, D. Carl, Sorensen. J. Mater. Sci. 46, 5305 (2011)

H. Shao, A. Wu, Y. Bao, Mater. Sci. Eng. A 680, 221 (2016)

Y. Chingfeng, C. Hsienchie, C. Wenhwa, Rsc. Adv. 5, 70609 (2015)

Y. Ma, H. Luo, W. Liu, X. Sheng, J. Mater. Sci. 27, 103 (2016)

V.L. Nguyen, S.H. Kim, J.W. Jeong, Electron. Mater. Lett. 13, 420 (2017)

O. Mokhtari, H. Nishikawa, J. Electron. Mater. 13, 4158 (2014)

M.L. Huang, Q. Zhou, N. Zhao, J. Mater. Sci. 24, 2624 (2013)

K. Kanlayasiri, K. Sukpimai, J. Alloys Compd. 25, 169 (2016)

R.M. Shalaby, Cryst. Res. Technol. 45, 427 (2010)

T. Satoh, T. Ishizaki, M. Usui, J. Mater Sci. 2, 1 (2018)

S. Tian, S. Li, J. Zhou, J Mater Sci. 28, 16120 (2017)

M.S. Yeh, Metall. Mater. Trans. A 3, 361 (2005)

J.B. Lee, H.Y. Hwang, M.W. Rhee, J. Electron. Mater. 44, 435 (2015)

Y.M. Zhang, J.R.G. Evans, S. Yang, J. Cheminform. 44, 81 (2013)

R.I. Made, C.L. Gan, L.L. Yan, J. Electron. Mater. 38, 365 (2009)

F.J. Wang, D.Y. Li, J.H. Wang, X.J. Wang, C.H. Dong, J. Mater. Sci. 28, 1631 (2017)

T. Shuang, L. Saipeng, Z. Jian, J. Mater. Sci. 28, 16120 (2017)

C.Y. Yu, J.G. Duh, J. Mater. Sci. 47, 6467 (2012)

K.N. Tu, Y. Liu, Mater. Sci. Eng. R 136, 1 (2019)

Y. Chingfeng, C. Hsienchie, C. Wenhwa, Rsc Adv. 5, 70609 (2015)

H.K. Shao, A.P. Wu, Y.D. Bao, Trans. Nonferr. Metal Soc. China 27, 722 (2017)

G.P. Vassilev, E.S. Dobrev, J.C. Tedenac, J Alloys Compd. 399, 118 (2005)

T.M. Korhonen, J.K. Kivilahti, J. Electron. Mater. 27, 149 (1998)

U.R. Kattner, W.J. Boettinger, J. Electron. Mater. 23, 603 (1994)

Acknowledgements

This research was financially supported by the National Natural Science Foundation of China (Grant No. 51865006,) and Natural Science Foundation of the Jiangsu Higher Education Institutions of China (Grant No. 18KJA460001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, L., Xiong, Y., Zhang, Y. et al. Microstructure and shear property of In-Sn-xAg solder joints fabricated by TLP bonding. J Mater Sci: Mater Electron 30, 18211–18219 (2019). https://doi.org/10.1007/s10854-019-02175-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02175-2