Abstract

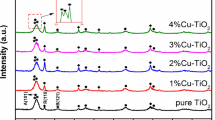

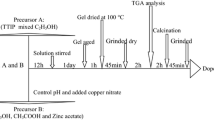

Cu–TiO2 and pure TiO2 were prepared by a facile one-step hydrothermal method and the obtained photocatalysts were tested by XRD, Raman, BET, XPS, DRS, PL, SEM and TEM, respectively. The results show that both pure and Cu–TiO2 consist of most rutile and a small amount of anatase, and present the morphology with nanoparticles, nanobucks and nanorods coexistence. The specific surface area and the separation rate of photogenerated electrons and holes increase after Cu doping. The photocatalytic experiment results illustrate that Cu–TiO2 exhibit better photocatalytic activity than pure TiO2 under simulated solar light. The enhanced photocatalytic performance is derived from the increased specific surface area providing more reaction sites and the conversion between Cu2+ and Cu+ increasing the separation rate of photogenerated pairs. 3%Cu–TiO2 shows the best photocatalytic activity owing to its largest specific surface area and lowest recombination rate. The degradation rate of RhB reaches 99.4% after 60 min, and the reaction rate constant is 0.076 min−1.

Similar content being viewed by others

References

Z. Fan, F. Meng, J. Gong, H. Li, Z. Ding, B. Ding, J. Mater. Sci. 27, 11866–11872 (2016)

M. Li, X. Zhang, Y. Liu, Y. Yang, Appl. Surf. Sci. 440, 1172–1180 (2018)

X. Jiang, Y. Zhang, J. Jiang, Y. Rong, Y. Wang, Y. Wu, C. Pan, J. Phys. Chem. C 116, 22619–22624 (2012)

J. Jalali, M. Mozammel, J. Mater. Sci. 28, 5336–5343 (2017)

Y. Chen, Q. Wu, C. Zhou, Q. Jin, Powder Technol. 322, 296–300 (2017)

T. Ali, Y.M. Hunge, A. Venkatraman, J. Mater. Sci. 29, 1209–1215 (2018)

Y.M. Hunge, M.A. Mahadik, R.N. Bulakhe, S.P. Yadav, J.J. Shim, A.V. Moholkar, J. Mater. Sci. 28, 17976–17984 (2017)

H. Kooshkia, A. Sobhani-Nasabb, M. Eghbali-Aranic, F. Ahmadid, V. Amerie, M. Rahimi-Nasrabadi, Sep. Purif. Technol. 211, 873–881 (2019)

S.M. Peymani-Motlagh, A. Sobhani-Nasab, M. Rostami, H. Sobati, M. Eghbali-Arani, M. Fasihi-Ramandi, M.R. Ganjali, J. Mater. Sci. 30, 6902–6909 (2019)

H. Yan, T. Zhao, X. Li, C. Hun, Ceram. Int. 41, 14204–14211 (2015)

T. Aguilar, J. Navas, R. Alcántara, C.F. Lorenzo, J.J. Gallardo, G. Blanco, J.M. Calleja, Chem. Phys. Lett. 571, 49–53 (2013)

S. Wang, K.K. Meng, L. Zhao, Q. Jiang, J.S. Lian, Ceram. Int. 40, 5107–5110 (2014)

V. Krishnakumar, S. Boobas, J. Jayaprakash, M. Rajaboopathi, B. Han, M.L. Kultanen, J. Mater. Sci. 27, 7438–7447 (2016)

A. Shafei, S. Sheibani, Mater. Res. Bull. 110, 198–206 (2019)

F. Gao, J. Jiang, L. Du, X. Liu, Y. Ding, Appl. Catal. A 568, 168–175 (2018)

C. Liu, J. Wang, W. Chen, C. Dong, C. Li, Chem. Eng. J. 280, 588–596 (2015)

F. Bensouici, M. Bououdina, A.A. Dakhel, R.T. Ighil, M. Tounane, A. Iratni, T. Souier, S. Liu, W. Cai, Appl. Surf. Sci. 395, 110–116 (2017)

Y. Wang, Y. Wu, H. Yang, X. Xue, Z. Liu, Vacuum 131, 58–64 (2016)

X. Fan, J. Fan, X. Hu, E. Liu, L. Kang, C. Tang, Y. Ma, H. Wu, Y. Li, Ceram. Int. 40, 15907–15917 (2014)

N.A. Kyeremateng, V. Hornebecq, P. Knauth, T. Djenizian, Electrochim. Acta 62, 192–198 (2012)

J. Ju, X. Chen, Y. Shi, J. Miao, D. Wu, Powder Technol. 237, 616–622 (2013)

M.S. Jyothi, P. Laveena, R. Shwetharani, G.R. Balakrishna, Mater. Res. Bull. 74, 478–484 (2016)

T.N. Ravishankar, G. Nagaraju, J. Dupont, Mater. Res. Bull. 78, 103–111 (2016)

Y. Zhang, T. Wang, M. Zhou, Y. Wang, Z. Zhang, Ceram. Int. 43, 3118–3126 (2017)

V.R. Bandi, C.M. Raghavan, B. Grandhe, S.S. Kim, K. Jang, D.S. Shin, S.S. Yi, J.H. Jeong, Thin Solid Films 547, 207–211 (2013)

M.C. Wu, P.Y. Wu, T.H. Lin, T.F. Lin, Appl. Surf. Sci. 430, 390–398 (2018)

H. Wang, W. Zhao, Y. Zhang, S. Zhang, Z. Wang, D. Zhao, Solid State Commun. 236, 27–31 (2016)

Y. Jiao, M. Zhu, F. Chen, J. Zhang, Chinese. J. Catal. 34, 585–592 (2013)

L. Long, L. Wu, X. Yang, X. Li, J. Mater. Sci. Technol. 30, 765–769 (2014)

R.A. Spurr, H. Myers, Anal. Chem. 29, 760–762 (1957)

H. Li, L. Shen, K. Zhang, B. Sun, L. Ren, P. Qiao, K. Pan, L. Wang, W. Zhou, Appl. Catal. B 220, 111–117 (2018)

T.T. Loan, N.A. Bang, V.H. Huong, N.N. Long, Opt. Mater. 69, 30–37 (2017)

R. Bashiri, N.M. Mohamed, C.F. Kait, S. Sufian, M. Khatani, J. Environ. Chem. Eng. 5, 3207–3214 (2017)

Y. Xu, J. Li, L. Yao, L. Li, P. Yang, N. Huang, Surf. Coat. Technol. 261, 436–441 (2015)

C. Jia, H.S. Chen, P. Yang, J. Ind. Eng. Chem. 58, 278–289 (2018)

J. Kong, C. Song, W. Zhang, Y. Xiong, M. Wan, Y. Wang, Superlattice Microst. 109, 579–587 (2017)

H. Jiang, J. Xing, Z. Chen, F. Tian, Q. Cuan, X. Gong, H. Yang, Catal. Today 225, 18–23 (2014)

M. Dorraj, M. Alizadeh, N.A. Sairi, W.J. Basirun, B.T. Goh, P.M. Woi, Y. Alias, Appl. Surf. Sci. 414, 251–261 (2017)

J. Liu, L. Han, N. An, L. Xing, H. Ma, L. Cheng, J. Yang, Q. Zhang, Appl. Catal. B 202, 642–652 (2017)

V. Moradi, M.B.G. Jun, A. Blackburn, R. Herring, Appl. Surf. Sci. 427, 791–799 (2018)

X. Yang, S. Wang, H. Sun, X. Wang, J. Lian, Trans. Nonferrous Met. Soc. China 25, 504–509 (2015)

Acknowledgements

This work was supported by the Applied Basic Research Programs of Sichuan Province, China (Grant No. 2019JY0664), the Open Research Subject of Powder Metallurgy Engineering Technology Research Center of Sichuan Province, China (Grant No. SC-FMYJ2017-03) and the Training Program for Innovation of Chengdu University, China (Grant Nos. CDU-CX-2019015, CDU-CX-2019020).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, X., Wen, G., Liu, H. et al. One-step hydrothermal synthesis and characterization of Cu-doped TiO2 nanoparticles/nanobucks/nanorods with enhanced photocatalytic performance under simulated solar light. J Mater Sci: Mater Electron 30, 13826–13834 (2019). https://doi.org/10.1007/s10854-019-01766-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01766-3