Abstract

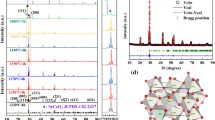

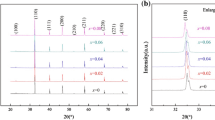

xSr0.7Ce0.2TiO3–(1 − x)Sr(Mg1/3Nb2/3)O3 ceramics, referred to xSCT–(1 − x)SMN, were successfully produced by conventional solid-state sintered technology. The compounds, belonging to perovskites with a secondary phase of CeO2, can be detected even with x down to 0.1 of SCT composition. The overall trend for grain growth illustrates the increase with increasing SCT doping level. The Raman peak at 825 cm−1 splits into two peaks and causes red shift phenomenon. XPS spectra indicate that Ti and Nb ions exist respectively in tetravalence and pentavalence, and Ce ions exist in trivalence and tetravalence. Dielectrics constant (ε r ) of SCT–SMN ceramics gradually increases with increasing theoretical dielectric polarizabilities. A wider width of the 825 cm−1 for FWHM of A1g mode Raman peaks suggests to a lower Q × f value. The increasing tolerance factor in agreement with temperature coefficient of resonant frequency (τ f ), denotes that the rise of perovskite symmetry. The 0.1SCT–0.9SMN ceramic sintered at 1450 °C for 4 h illustrates excellent microwave dielectric properties with ε r ~ 35.4, Q × f ~ 11282 GHz and τ f ~ 1.7 ppm/°C. Activation energies of 0.1SCT–0.9SMN ceramic at 100, 300 and 500 V, are ~0.436, 0.427 and 0.331 eV, respectively, indicative of a decreased trend with external electric field.

Similar content being viewed by others

References

L. Li, X.M. Chen, X.C. Fan, J. Eur. Ceram. Soc. 26, 2817 (2006)

K.W. Tay, W.F. Wu, Procedia Eng. 36, 462 (2012)

B. Ullah, W. Lei, Z.Y. Zou, X.H. Wang, W.Z. Lu, J. Alloys Compd. 695, 648 (2016)

B. Ulah, W. Lei, Q.S. Cao, Z.Y. Zou, X.K. Lan, X.H. Wang, W.Z. Lu, J. Am. Ceram. Soc. 99, 3286 (2016)

B. Ulah, W. Lei, X.H. Wang, G.F. Fan, X.C. Wang, W.Z. Lu, RSC Adv. 6, 91679 (2016)

G. Subodh, M.T. Sebastian, Mater. Sci. Eng. B 136, 50 (2007)

G. Subodh, J. James, M.T. Sebastian, R. Paniago, A. Dias, R.L. Moreira, Chem. Mater. 19, 4077 (2007)

B. Ullah, W. Lei, X.Q. Song, X.H. Wang, W.Z. Lu, J. Eur. Ceram. Soc. 37, 3051 (2017)

P.J. Chang, C.T. Chia, I.N. Lin, J.F. Lee, C.M. Lin, K.T. Wu, Appl. Phys. Lett. 88, 242907 (2006)

S. Nomuro, K. Toyama, K. Kaneta, Jpn. J. Appl. Phys. 21, L624 (1982)

C.L. Huang, S.S. Liu, C.C. Chen, J. Alloys Compd. 468, L13 (2009)

F. Liang, W.Z. Lu, D.X. Zhou, X.H. Wang, J. Electroceram. 21, 431 (2007)

H.J. Lee, H.M. Park, Y.W. Song, Y.K. Cho, J. Am. Ceram. Soc. 84, 2105 (2001)

X.Q. Song, K. Du, Z.Y. Zou, Z.H. Chen, W.Z. Lu, S.H. Wang, W. Lei, Ceram. Int. 43, 14453 (2017)

A. Dutta, C. Bharti, T.P. Sinha, Phys. B 403, 3389 (2008)

S. Qin, X. Wu, F. Seifert, J. Chem. Soc. Dalton Trans. 19, 3751 (2002)

H. Zheng, G.D.C. Csete de Györgyfalva, R. Quimby, H. Bagshaw, R. Ubic, I.M. Reaney, J. Yarwood, J. Eur. Ceram. Soc. 23, 2653 (2003)

H. Zheng, H. Bagshaw, G.D.C. Csete de Györgyfalva, I.M. Reaney, R. Ubic, J. Yarwood, J. Appl. Phys. 94, 2948 (2003)

D. Zhou, L.X. Pang, H. Wang, J. Guo, X. Yao, C.A. Randall, J. Mater. Chem. 21, 18412 (2011)

R.L. Moreira, R.P.S.M. Lobo, G. Subodh, M.T. Sebastian, F.M. Matinaga, Chem. Mater. 19, 6548 (2007)

A. Manan, A. Ullah, A.S. Ahmad, Mater. Sci. Pol. 34, 1 (2016)

R. Singh, K. Kambale, A.R. Kulkarni, C.S. Harendranath, Mater. Chem. Phys. 138, 905 (2013)

R. Lowndes, M. Deluca, F. Azough, R. Freer, J. Appl. Phys. 113, 044115 (2013)

R.C.D. Costa, A.D. Rodrigues, T.R. Cunha, J.W.M. Espinosa, P.S. Pizani, Ceram. Int. 43, 116 (2017)

Q. Wu, J. Xu, Q. Zhuang, S. Sun, Solid State Ion. 177, 1483 (2006)

W. Gong, B. Ullah, W. Lei, G.F. Fan, X.H. Wang, W.Z. Lu, Ceram. Int. 43, 3051 (2016)

S.K. Jaiswal, J. Hong, K.J. Yoon, J.W. Son, H.W. Lee, J.H. Lee, Ceram. Int. 42, 10366 (2016)

E. Ksepko, E. Talik, A. Ratuszna, A. Molak, Z. Ujma, I. Gruszka, J. Alloys Compd. 386, 35 (2005)

C.E. Huang, X. Lu, M. Lu, Y. Huan, Ceram. Int. 43, 10624 (2017)

C.F. Xing, J.X. Bi, H.T. Wu, J. Alloys Compd. 719, 58 (2017)

P.F. Ning, L.X. Li, P. Zhang, W.S. Xia, Ceram. Int. 38, 1391 (2012)

Y.Z. Hao, H. Yang, G.H. Chen, Q.L. Zhang, J. Alloys Compd. 552, 173 (2013)

S.K. Singh, V.R.K. Murthy, Ceram. Int. 42, 7284 (2016)

F. Liu, C.L. Yuan, X. Liu, J.J. Qu, G.H. Chen, C. Zhou, Mater. Res. Bull. 70, 678 (2015)

P.F. Liang, X.L. Chao, Z.P. Yang, Mater. Chem. Phys. 167, 103 (2015)

M. Mondal, S. Das, T. Badapanda, T.P. Sinha, P.M. Sarun, Phys. B 508, 124 (2017)

Acknowledgements

Financial support of the National Natural Science Foundation of China (Grant No. 11464006) is gratefully acknowledged by the authors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meng, L., Yuan, C., Wang, Z. et al. Microwave dielectric properties of Sr0.7Ce0.2TiO3–Sr(Mg1/3Nb2/3)O3 ceramics. J Mater Sci: Mater Electron 29, 2668–2675 (2018). https://doi.org/10.1007/s10854-017-8193-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-8193-7