Abstract

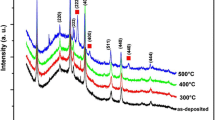

In this work, nickel (Ni) doped indium sulfide (In2S3) films have been prepared by the spray pyrolysis (CSP) technique on glass substrates at 350 °C. The Ni doping level was changed with Ni:In (0, 2 and 4% in solution). The structural studies reveal that the deposited films are polycrystalline in nature exhibiting cubic structure. The crystallite size decreases from 27.5 to 23 nm and the root mean square roughness values increase from 13 to 18 nm. The transmission coefficient is about 70–55% in the visible region and 85–75% in near-infrared region. The band gap energy increases with nickel content from 2.74 to 2.82 eV for direct transitions. The refractive index values of In2S3:Ni thin films decrease from 2.43 to 2.40 and the extinction coefficient values are in the range 0.01–0.20. Besides, the AC conductivity contribution is interpreted using the universal Jonscher’s power law and it is found thermally activated and it can be described by the correlated barrier-hopping models. These studies help to form significant correlation between temperature and activation energy. Nyquist plots show that the electrical response is accurately fitted by the Cole–Cole model and represented by an equivalent electrical circuit which consists of a parallel combination of a resistance and a constant phase element. From this analysis, the evidence of grain boundary conduction has been observed.

Similar content being viewed by others

References

A.A. El Sbazly, D. AbdElhady, H.S. Metwally, M.A.M. Seyam, J. Phys. 10, 5943–5954 (1998)

M. Kilani, B. Yahmadi, N.K. Turki, M. Castagné, J. Mater. Sci. 46, 6293–6300 (2011)

K. Hara, K. Sayama, H. Arakawa, Sol. Energy Mater. Sol. Cells 62, 441–447 (2000)

R. Nomura, S. Inazawa, K. Kanaya, H. Matsuda, Appl. Organomet. Chem. 3, 195–197 (1989)

E. Dalas, L. Kobotiatis, J. Mater. Sci. 28, 6595–6597 (1993)

Y. He, D. Li, G. Xiao, W. Chen, Y. Chen, M. Sun, H. Huang. X. Fu, J. Phys. Chem. C, 113, 5254–5262 (2009)

N. Barreau, Sol. Energy 83, 363–371 (2009)

D. Braunger, D. Hariskos, T. Walter, H.W. Schock, Sol. Energy Mater. Sol. Cells 40, 97–102 (1996)

S. Cingarapu, M.A. Ikenberry, D.B. Hamal, C.M. Sorensen, K. Hohn, K.J. Klabunde, Langmuir 28, 3569–3575 (2012)

L.J. Liu, W.D. Xiang, J.S. Zhong, X.Y. Yang, X.J. Liang, H.T. Liu, W. Cai, J. Alloys Compd. 493, 309–313 (2010)

Z. Li, X. Tao, Z. Wu, P. Zhang, Z. Zhang, Ultrason. Sonochem. 16, 221–224 (2009)

H. Spasevska, C.C. Kitts, C. Ancora, G. Ruani, Int. J. Photoenergy (2011). doi:10.1155/2012/637943

A. Akkari, C. Guasch, M. Castagne, N. Ka. Turki, J. Mater. Sci. 46, 6285–6292 (2011)

A. Timoumi, H. Bouzouita, B. Rezig, Thin Solid Films 519, 7615–7619 (2011)

J.J. Lee, J.D. Lee, B.Y. Ahn, K.H. Kim, J. Korean Phys. Soc. 53, 3255–3261 (2008)

S. Ghosh, M. Saha, V.D. Ashok, A. Chatterjee, S.K. De, Nanotechnology 27, 155708 (2016)

R. Lucena, J.C. Conesa, I. Aguilera, P. Palacios, P. Wahnon, J. Mater. Chem. A 2, 8236–8245 (2014)

B. Asenjo, J. Herrero, M. Teresa, Gutiérrez, Mater. Res. Soc. Symp. Proc. 1165, M05–M08 (2009)

B.D. Cullity, Elements of X-ray Diffraction. (Addison-Wesley, Reading, 1978)

A. Khorsand. W.H. Zak, M.E. Abd.Majid, R. Abrishami, Yousefi, Solid State Sci. 13, 251–256 (2011)

K. Ravichandran, P. Philominathan, Sol. Energy 82, 1062–1066 (2008)

V. Bilgin, S. Kose, F. Atay, I. Akyuz, Mater. Chem. Phys. 94, 103–108 (2005)

P. Roy, S.K. Srivastava, Thin Solid Films 496, 293–298 (2006)

G.B. Kamath, C.M. Joseph, C.S. Menon, Mater. Lett. 57, 730–733 (2002)

S. Rajeh, A. Mhamdi, K. Khirouni, M. Amlouk, S. Guermazi, Opt. Laser Technol. 69, 113–121 (2015)

M. Kraini, N. Bouguila, I. Halidou, A. Timoumi, S. Alaya, Mater. Sci. Semicond. Process. 16, 1388–1396 (2013)

F. Urbach, Phys. Rev. 92, 1324 (1953)

M. Kraini, N. Bouguila, I. Halidou, A. Moadhen, C. Vázquez-Vázquez, M.A. López-Quintela, S. Alaya, J. Electron. Mater. 44, 2536–2543 (2015)

J. Koaib, N. Bouguila, M. Kraini, A. Mhamdi, I. Halidou, M. Ben Salem, H. Bouzouita, S. Alaya, J. Mater. Sci.: Mater. Electron. 27, 9216–9225 (2016)

M. Kraini, N. Bouguila, J. Koaib, C. Vázquez-Vázquez, M.A. López-Quintela, S. Alaya, J. Electron. Mater. 45, 5936–5947 (2016)

C. Guillén, T. Garcia, J. Herrero, M.T. Gutiérrez, F. Briones, Thin Solid Films 451, 112–115 (2004)

P.J.L. Herve, L.K.J. Vandamme, J. Appl. Phys. 77, 5476–5477 (1995)

S.P. Nehra, S. Chander, A. Sharma, M.S. Dhaka, Mater. Sci. Semicond. Process. 40, 26–34 (2015)

M.M. El-Nahass, B.A. Khalifa, H.S. Soliman, M.A.M. Seyam, Thin Solid Films 515, 1796–1801 (2006)

A. Timoumi, H. Bouzouita, B. Rezig, Aust. J. Basic Appl. Sci. 7, 448–456 (2013)

A.K. Jonscher, Nature 267, 673 (1977)

N.F. Mott, E.A. Davis, Electronic Process in Non-crystalline Materials. (Clarendon Press, Oxford, 1979)

D.K. Pradhan, B.K. Samantary, R.N.P. Chaudhary, A.K. Thakur, Mater. Sci. Eng. B 116, 7 (2005)

A.A. Atta, J. Alloys Compd 480, 564 (2009)

A.A. Dakhel, J. Phys. Chem. Solids 65, 1765 (2004)

F. Salman, Turk. J. Phys. 28, 41 (2004)

B. Roy, S. Chakrabarty, O. Mondal, M. Pal, A. Dutta, Mater. Charact. 70, 1–7 (2012)

P. Zoltowski, J. Electroanal. Chem. 443, 149 (1998)

E.J. Abram, D.C. Sinclair, A.R. West, J. Electroceram. 10, 165 (2003)

J.B. Jorcin, M.E. Orazem, N. Pebere, B. Tribollet, Electrochim. Acta 51, 1473 (2006)

B.N. Parida, P.R. Das, R. Padhee, R.N.P. Choudhary, J. Alloys Compd. 540, 267 (2012)

M. Nadeem, M.J. Akhtar, J. App. Phys. 104, 103713 (2008)

M. Younes, M. Nadeem, M. Atif, R. Grossinger, J. Appl. Phys. 109, 93704 (2010)

T. Nagata, T. Shimura, A. Ashida, N. Fujimura, T. Ito, J. Cryst. Growth 533, 237 (2002)

P.S. Anantha, K. Harharan, Mat. Sci. Eng. B 121, 12 (2005)

R. Bellouz, S. Kallel, K. Khirouni, O. Pena, M. Oumezzin, Ceram. Int. 41, 1929 (2015)

W. Cao, R. Gerhardt, Solid State Ion. 42, 213 (1990)

V. Hornebecq, C. Elissalde, V. Porokhonskyy, V. Bovtun, J. Petzelt, I. Gregora, M. Maglione, J. Ravez, J. Phys. Chem. Solids 64, 471 (2003)

Acknowledgements

This work was supported by the Tunisian Ministry of Higher Education and Scientific Research, MINECO (Spain), FEDER Funds (Projects MAT2015-67458-P and CTQ2016-79461-R) and Fundación Ramón Areces, Spain (Project 2016-PO024).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kraini, M., Bouguila, N., Moutia, N. et al. Properties of nickel doped In2S3 thin films deposited by spray pyrolysis technique. J Mater Sci: Mater Electron 29, 1888–1906 (2018). https://doi.org/10.1007/s10854-017-8099-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-8099-4