Abstract

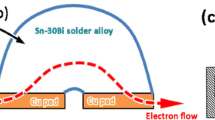

The bonding process of Co/Sn/Cu couple has been conducted at 270 °C. The microstructure evolution was observed. The spreading test of Cu/Sn–xCo and Co/Sn–xCu was conducted to explain the microstructure evolution of Co/Sn/Cu couple. The results showed that the main interfacial intermetallic compounds (IMCs) layer of Cu/Sn side of Co/Sn/Cu couple was (Cu, Co)6Sn5, as the dissolution of Co from Co substrate to solder layer. The (Cu, Co)6Sn5 IMCs layer only thickened slightly during bonding process as large amount of the (Cu, Co)6Sn5 IMCs layer dissociated into solder alloy layer. As the adsorbing effect of Co substrate on the dissociating (Cu, Co)6Sn5 IMCs, there was a thick (Cu, Co)6Sn5 IMCs layer covered on the surface of Co substrate at the early stage of bonding process. For longer bonding time (> 30 min), the (Co, Cu)Sn and (Co, Cu)Sn3 IMCs generated on the Co/(Cu, Co)6Sn5 interface as the diffusion of Sn atom from liquid solder alloy to Co/(Cu, Co)6Sn5 interface. The Co/Sn/Cu joint bonded for 60 min could work at the temperature of 300 °C. The shear strength of joints bonded for 20 and 30 min was approximate 45 MPa. The shear strength of joints bonded for a time more than 30 min declined gradually as the generation of (Co, Cu)Sn3 IMCs.

Similar content being viewed by others

References

C. Lee, W.F. Huang, J.S. Shie, Wafer bonding by low-temperature soldering. Sens. Actuators A Phys. 85, 330–334 (2000)

C. Lee, A. Yu, L. Yan, H. Wang, J.H. He, Q.X. Zhang, J.H. Lau, Characterization of intermediate In/Ag layers of low temperature fluxless solder based wafer bonding for MEMS packaging. Sens. Actuators A Phys. 154, 85–91 (2009)

A. Sigl, S. Pargfrieder, C. Pichler, C. Scheiring, in: International Conference on Electronic Packaging Technology & High Density Packaging, Advanced chip to wafer bonding: A flip chip to wafer bonding technology for high volume 3DIC production providing lowest cost of ownership, (Icept-Hdp, 2009), pp. 932–936

K.N. Tu, K. Zeng, Tin–lead (SnPb) solder reaction in flip chip technology. Mater. Sci. Eng. 34, 1–58 (2001)

M.G. Cho, S.K. Kang, D.Y. Shih, H.M. Lee, Effects of minor additions of Zn on interfacial reactions of Sn–Ag–Cu and Sn–Cu solders with various Cu substrates during thermal aging. J. Electron. Mater. 36, 1501–1509 (2007)

H. Nishikawa, Y.P. Jin, T. Takemoto, Interfacial reaction between Sn–0.7Cu (-Ni) solder and Cu substrate. J. Electron. Mater. 35, 1127–1132 (2006)

C.M. Chuang, K.L. Lin, Effect of microelements addition on the interfacial reaction between Sn-Ag-Cu solders and the Cu substrate. J. Electron. Mater. 32, 1426–1431 (2003)

W. Zhang, Y. Zhong, C. Wang, Effect of diamond additions on wettability and distribution of SnAgCu composite solder. J. Mater. Sci. Technol., 28 661–665 (2012)

O.M. Abdelhadi, L. Ladani, IMC growth of Sn–3.5Ag/Cu system: combined chemical reaction and diffusion mechanisms. J. Alloys Compd. 537, 87–99 (2012)

J.W. Yoon, S.B. Jung, Investigation of interfacial reactions between Sn–5Bi solder and Cu substrate. J. Alloys Compd. 359, 202–208 (2003)

Z. Lai, D. Ye, Microstructure and properties of Sn–10Bi– xCu solder alloy/joint. J. Electron. Mater. 45, 3702–3711 (2016)

H. He, H. Zhao, F. Guo et al., Bi layer formation at the anode interface in Cu/Sn–58Bi/Cu solder joints with high current density. J. Mater. Sci. Technol. 28(1), 46–52 (2012)

L. Qi, J. Huang, H. Zhang, X. Zhao, H. Wang, D. Cheng, Growth behavior of intermetallic compounds at SnAgCu/Ni and Cu interfaces. J Mater. Eng. Perform. 19, 129–134 (2010)

C. Chen, C.E. Ho, A.H. Lin, G.L. Luo, C.R. Kao, Long-term aging study on the solid-state reaction between 58Bi42Sn solder and Ni substrate. J. Electron. Mater. 29, 1200–1206 (2000)

Y.S. Huang, H.Y. Hsiao, C. Chen, K.N. Tu, The effect of a concentration gradient on interfacial reactions in microbumps of Ni/SnAg/Cu during liquid-state soldering. Scripta Mater. 66, 741–744 (2012)

T.C. Liu, Y.S. Huang, C. Chen, Concentration gradient of Ni in reduced SnAg thickness in Ni/SnAg/Cu microbumps during solid-state aging. ECS Solid State Lett. 2, 15–18 (2012)

Z. Lai, X. Kong, Q. You, X. Cao, Microstructure and mechanical properties of Co/Sn–10Bi couple and Co/Sn–10Bi/Co joint. Microelectron. Reliab. 68, 69–76 (2017)

C.H. Wang, C.C. Wen, C.Y. Lin, Solid-state interfacial reactions of Sn and Sn–Ag–Cu solders with an electroless Co(P) layer deposited on a Cu substrate. J. Alloys Compd. 662, 475–483 (2015)

C. Wang, C. Kuo, Interfacial reactions between eutectic Sn–Pb solder and Co substrate. J. Mater. Sci. 46, 2654–2661 (2011)

C. Wang, S. Chen, Sn/Co solid/solid interfacial reactions. Intermetallics 16, 524–530 (2008)

C.H. Wang, C.Y. Kuo, N.C. Yang, Phase equilibria of the ternary Sn–Pb–Co system at 250 °C and interfacial reactions of Co with Sn–Pb alloys. J. Electron. Mater. 44, 4567–4575 (2015)

F. Gao, T. Takemoto, H. Nishikawa, Effects of Co and Ni addition on reactive diffusion between Sn–3.5Ag solder and Cu during soldering and annealing. Mater. Sci. & Eng. A 420, 39–46 (2006)

Y.W. Wang, Y.W. Lin, C.T. Tu, C.R. Kao, Effects of minor Fe, Co, and Ni additions on the reaction between SnAgCu solder and Cu. J. Alloys Compd. 478, 121–127 (2009)

Y.L. Tseng, Y.C. Chang, C.C. Chen, Co effects upon intermetallics growth kinetics in Sn–Cu–Co/Ni and Sn–Cu–Co/Cu couples. J. Electron. Mater. 44, 581–589 (2015)

K.S. Kim, S.H. Huh, K. Suganuma, Effects of fourth alloying additive on microstructures and tensile properties of Sn–Ag–Cu alloy and joints with Cu. Microelectron. Reliab. 43, 259–267 (2003)

G.G. Meng, T. Takemoto, H. Nishikawa, Correlations between IMC thickness and three factors in Sn–3Ag–0.5Cu alloy system. Trans. Nonferr. Met. Soc. China 17, 686–690 (2007)

M. Schaefer, R.A. Fournelle, J. Liang, Theory for intermetallic phase growth between cu and liquid Sn–Pb solder based on grain boundary diffusion control. J. Electron. Mater. 27, 1167–1176 (1998)

C.H. Wang, C.Y. Kuo, Growth kinetics of the solid-state interfacial reactions in the Sn–Cu/Co and Sn/Co–Cu couples. Mater. Chem. Phys. 130, 651–656 (2011)

M. Jiang, J. Sato, I. Ohnuma et al., A thermodynamic assessment of the Co–Sn system. Calphad-Comput. Coupling Ph. Diagr. Thermochem. 28, 213–220 (2004)

Acknowledgements

The authors would like to express their gratitude for projects supported by the National Natural Science Foundation of China (Grant Nos. 51374153 and 51574181) and Supported by State Key Lab of Advanced Welding and Joining, Harbin Institute of Technology (Grant No. AWJ-Z15-02).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Du, C., Wang, X. & Tian, S. Effect of bonding time on the microstructure and mechanical properties of Co/Sn/Cu joint. J Mater Sci: Mater Electron 29, 455–466 (2018). https://doi.org/10.1007/s10854-017-7934-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7934-y