Abstract

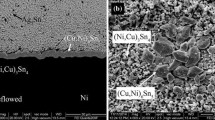

The interfacial reaction, morphology, activation energies and growth behavior of interfacial intermetallic compounds (IMCs) between the Sn–3Ag–0.5Cu (in wt%) solder and Cu substrate during reflow at 280 °C for 10 min and aging at different temperatures for up to 360 h were investigated, and the growth kinetics of the interfacial Cu–Sn binary IMC layers were monitored during the isothermal aging. The results showed that the thickness of IMCs increased linearly with square root of aging time, and the diffusion coefficient related to the Cu–Sn IMC layer increased with increasing aging temperature. During aging at medium temperature (180 °C), the scallop-like Cu6Sn5 IMC layer at the SAC305/Cu interface gradually transformed into planar type with prolonged aging time. Nevertheless, in the case of high temperature (200 °C) aging, the solder/Cu6Sn5 interface became uneven because the Cu atoms came from the bulk solder would accumulate on the Cu6Sn5 IMC surface to directly thicken the existed IMC layer. Beside, the Kirkendall voids within Cu3Sn layer and the neighborhood of the Cu3Sn/Cu interface almost aggregated into continuous regions to formed micro-voids. The activation energies of the total Cu–Sn, Cu6Sn5 and Cu3Sn IMCs were obtained by plotting the diffusion constants (D) as a function of the aging temperature (1/T), and were 115.2, 122 and 98 kJ/mol, respectively.

Similar content being viewed by others

References

T.L. Yang, J.Y. Wu, C.C. Li, S. Yang, C.R. Kao, Low temperature bonding for high temperature applications by using SnBi solders. J. Alloys Compd. 647(25), 681–685 (2015)

C. Key Chung, Y.J. Chen, C.C. Li, C.R. Kao, The critical oxide thickness for Pb-free reflow soldering on Cu substrate. Thin Solid Films 520(16), 5346–5352 (2012)

Y.W. Wang, Y.W. Lin, C.R. Kao, Kirkendall voids formation in the reaction between Ni-doped SnAg lead-free solders and different Cu substrates. Microelectron. Reliab. 49(3), 248–252 (2009)

M.Y. Tsai, S.C. Yang, Y.W. Wang, C.R. Kao, Grain growth sequence of CuSn in the Cu/Sn and Cu/Sn–Zn systems. J. Alloys Compd. 494(1), 123–127 (2010)

Y.W. Wang, Y.W. Lin, C.T. Tu, C.R. Kao, Effects of minor Fe, Co, and Ni additions on the reaction between SnAgCu solder and Cu. J. Alloys Compd. 478(1), 121–127 (2009)

W.C. Luo, C.E. Ho, J.Y. Tsai, Y.L. Lin, C.R. Kao, Solid-state reactions between Ni and Sn–Ag–Cu solders with different Cu concentrations. Mater. Sci. Eng. 396(1), 385–391 (2005)

S.C. Yang, C.C. Chang, M.H. Tsai, C.R. Kao, Effect of Cu concentration, solder volume, and temperature on the reaction between SnAgCu solders and Ni. J. Alloys Compd. 499(2), 149–153 (2010)

H.W. Yang, J.Y. Wu, Z.X. Zhu, C.R. Kao, Effects of surface diffusion and reaction-induced volume shrinkage on morphological evolutions of micro joints. Mater. Chem. Phys. 191, 13–19 (2017)

Y.W. Wang, Y.W. Lin, C.R. Kao, Inhibiting the formation of microvoids in CuSn by additions of Cu to solders. J. Alloys Compd. 493(1), 233–239 (2010)

F. Wang, L. Zhou, X. Wang et al., Microstructural evolution and joint strength of Sn–58Bi/Cu joints through minor Zn alloying substrate during isothermal aging. J. Alloys Compd. 688, 639–648 (2016)

X. Hu, T. Xu, L.M. Keer et al., Microstructure evolution and shear fracture behavior of aged Sn3Ag0.5Cu/Cu solder joints. Mater. Sci. Eng. A 673, 167–177 (2016)

L. Zhang, L. Sun, Y.H. Guo, Microstructures and properties of Sn58Bi, Sn35Bi0.3Ag, Sn35Bi1.0Ag solder and solder joints. J. Mater. Sci. 26(10), 1–6 (2015)

L. Yang, Y. Zhang, J. Dai et al., Microstructure, interfacial IMC and mechanical properties of Sn–0.7Cu-x Al (x = 0–0.075) lead-free solder alloy. Mater. Des. 67, 209–216 (2015)

L.P. Lehman, S.N. Athavale, T.Z. Fullem et al., Growth of Sn and intermetallic compounds in Sn–Ag–Cu solder. J. Electron. Mater. 33(12), 1429–1439 (2004)

H. Nishikawa, N. Iwata, Formation and growth of intermetallic compound layers at the interface during laser soldering using Sn–Ag Cu solder on a Cu Pad. J. Mater. Process. Technol. 215(215), 6–11 (2015)

Y. Huang, Z. Xiu, G. Wu et al., Improving shear strength of Sn–3.0Ag–0.5Cu/Cu joints and suppressing intermetallic compounds layer growth by adding graphene nanosheets. Mater. Lett. 169, 262–264 (2016)

C. Yang, F. Le, SWR Lee, Experimental investigation of the failure mechanism of Cu–Sn intermetallic compounds in SAC solder joints. Microelectron. Reliab. 62, 130–140 (2016)

AiTingTan,AiWen Tan, Farazila Yusof, Evolution of microstructure and mechanical properties of Cu/SAC305/Cu solder joints under the influence of low ultrasonic power. J. Alloys Compd. 705, 188–197 (2017)

D.Q. Yu, C.M.L. Wu, C.M.T. Law, L. Wang, J.K.L. Lai, Intermetallic compounds growth between Sn–3.5Ag lead-free solder and Cu substrate by dipping method. J. Alloys Compd. 392(1), 192–199 (2005)

L. Zhang, X.Y. Fan, C.W. He et al., Intermetallic compound layer growth between SnAgCu solder and Cu substrate in electronic packaging. J. Mater. Sci. 24(9), 3249–3254 (2013)

H.K. Kim, K.N. Tu, Kinetic analysis of the soldering reaction between eutectic SnPb alloy and Cu accompanied by ripening. Phys. Rev. B, Condens. Matter 53(23), 16027–16033 (1996)

X. Hu, Y. Li, Z. Min, Interfacial reaction and IMC growth between Bi-containing Sn0.7Cu solders and Cu substrate during soldering and aging. J. Alloys Compd. 582, 341–347 (2014)

X. Hu, Y. Li, Z. Min, Interfacial reaction and growth behavior of IMCs layer between Sn–58Bi solders and a Cu substrate. J. Mater. Sci. 24(6), 2027–2034 (2013)

J. Shen, M. Zhao, P. He et al., Growth behaviors of intermetallic compounds at Sn–3Ag–0.5Cu/Cu interface during isothermal and non-isothermal aging. J. Alloys Compd. 574(10), 451–458 (2013)

X. Hu, Z. Ke, Growth behavior of interfacial Cu–Sn intermetallic compounds of Sn/Cu reaction couples during dip soldering and aging. J. Mater. Sci. 25(2), 936–945 (2014)

M. Yang, Y.H. Ko, J. Bang, T.S. Kim, C.W. Lee, M. Li, Effects of Ag addition on solid-state interfacial reactions between Sn–Ag–Cu solder and Cu substrate. Mater. Charact. 124, 250–259 (2017)

M. Yang, M. Li, J. Kim, Texture evolution and its effects on growth of intermetallic compounds formed at eutectic Sn37Pb/Cu interface during solid-state aging. Intermetallics 31(4), 177–185 (2012)

A.M. Gusak, K.N. Tu, Kinetic theory of flux-driven ripening. Phys. Rev. B 66(11), 115403 (2002)

Acknowledgements

This work was supported by the Nature Science Foundation of China (Nos. 51465039, 51665038, 51765040) and Nature Science Foundation of Jiangxi Province (20161BAB206122).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, T., Hu, X., Li, Y. et al. The growth behavior of interfacial intermetallic compound between Sn–3.5Ag–0.5Cu solder and Cu substrate under different thermal-aged conditions. J Mater Sci: Mater Electron 28, 18515–18528 (2017). https://doi.org/10.1007/s10854-017-7799-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7799-0