Abstract

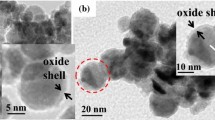

LCNO (Li0.35Cr0.10Ni0.55O) sample was prepared by modified sol–gel method and annealed at different temperatures (400, 800 and 1000 °C) in order to have variation in the size of grains and grain boundaries. The crystallinity and phase purity have been studied by employing the X-ray diffraction (XRD) technique. All the samples are crystallize to cubic symmetry with \(Fm\overline 3 m\) space group and, XRD patterns could be analysed by employing the Rietveld method. The microstructural and elemental analysis of the sample has been carried out by using the field emission scanning electron microscopy (FESEM). The grain size increases with the increase in annealing temperature which leads to increase the dielectric constant with the grain size. Interestingly, the enhancement of dielectric constant with the increase in grain size could be explained by the Barrier Layer Capacitances (BLCs) model. The frequency dispersion of dielectric constant could be explained by the Maxwell Wagner relaxation model. Furthermore, it is also observed that the activation energy obtained from dielectric relaxation analysis is comparable with the activation energy obtained by impedance analysis (Cole–Cole). In addition, the correlation between microstructure (grains and grain boundaries) with electrical transport properties of LCNO has been reported.

Similar content being viewed by others

References

S.M. Spearing, Acta Mater. 48, 179 (2000)

N. Setter, R. Waser, Acta Mater. 48, 151 (2000)

K. V. Rao, A. Smakula, J. Appl. Phys. 36, 6 (1965)

A.J. Bosman, C. Crevecoeur, Phys. Rev. 144, 2 (1966).

Q. Zheng, H. Fan, C. Long, J. Alloys Compd. 511, 90 (2012)

H. A. Ardakani, M. Alizadeh, R. Amini, M. R. Ghazanfari, Ceram. Int. 38, 4217 (2012)

J.V. Elp, H. Eskes, P. Kuiper, G.A. Sawatzky, Phys. Rev. B 45, 1612 (1992)

P. Thongbai, T. Yamwong, S. Maensiri, J. Appl. Phys. 104, 074109 (2008)

P. Thongbai, S. Pongha, T. Yamwong, S. Maensiri, Appl. Phys. Lett. 94, 022908 (2009)

V.S. Puli, R. Picchini, C. Orozco, C.V. Ramana, Chem. Phys. Lett. 649, 115 (2016)

J. Khemprasit, B. Khumpaitool, Ceram. Int. 41, 663 (2015)

S. Manna, S.K. De, Solid State Commun. 150, 399 (2010)

L. Kumar, P. Kumar, A. Narayan, M. Kar, Int. Nano Lett. 3, 8 (2013)

L. Kumar, M. Kar, J. Magn. Magn. Mater. 323, 2042 (2011)

D. Burow, K. Sergeeva, S. Calles, K. Schorb, A. Borger, C. Roth, P. Heitjans, J. Power Sources 307, 806 (2016)

A. Baykal, I.A. Auwal, S. Güner, H. Sözeri, J. Magn. Magn. Mater. 430, 29 (2017)

N. Sharma, B.S. Patial, N. Thakur, Appl. Phys. A 122, 209 (2016)

S. Supriya, S. Kumar, M. Kar, J. Appl. Phys. 120, 215106 (2016)

Y. Zhi, A. Chen, J. Appl. Phys. 91, 794 (2002)

Y.D. Kolekar, L.J. Sanchez, C.V. Ramana, J. Appl. Phys. 115, 144106 (2014)

D.C. Sinclair, T.B. Adams, F.D. Morrison, A.R. West, Appl. Phys. Lett. 80, 2153 (2002)

Y. Lin, J. Wang, L. Jiang, Y. Chen, C.W. Nan, Appl. Phys. Lett. 85, 5664 (2004)

Y.H. Lin, M. Li, C.W. Nan, J. Li, Appl. Phys. Lett. 89, 032907 (2006)

B. Cheng, Y.H. Lin, A. Mei, J.N. Cai, C.W. Nan, J. He, Appl. Phys. Lett. 92, 142903 (2008)

I.I. Fabrikant, H. Hotop, J. Chem. Phys. 128, 124308 (2008)

R.A. Pawar, S.S. Desai, S.M. Patange, S.S. Jadhav, K.M. Jadhav, Physica B 510, 74 (2017)

T.I. Chupakhina, N.I. Kadyrova, N.V. Melnikova, O.I. Gyrdasova, E.A. Yakovleva, Y.G. Zainulin, Mater. Res. Bull. 77, 190 (2016)

S. Supriya, S. Kumar, M. Kar, J. Mater. Sci. 17, 1 (2017)

C.J. Raj, G. Paramesh, B.S. Prakash, K.R.S. Preethi, K.B.R. Varma, Mater. Res. Bull. 74, 1 (2016)

A. Chouket, W.C. Koubaa, A. Cheikhrouhou, V. Optasanu, O. Bidault, M. Khitouni, J. Alloys Compd. 662, 467 (2016)

Acknowledgements

Authors are thankful to financial assistance for UGC, UGC-ref. No.: 4050, 4051/(NET-June 2013) for JRF and IIT Patna for providing the working platform.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, S., Supriya, S., Pradhan, L.K. et al. Effect of microstructure on electrical properties of Li and Cr substituted nickel oxide. J Mater Sci: Mater Electron 28, 16679–16688 (2017). https://doi.org/10.1007/s10854-017-7580-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7580-4