Abstract

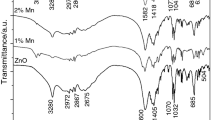

In this study, dually doped samples of Zn1−x−y Al x Me y O (Me: Ga, In) were prepared by sol–gel process followed by hot isostatic pressing for high temperature thermoelectric applications. Material characterizations were performed with differential thermal analysis-thermogravimetry, Fourier transform infrared spectroscopy and X-ray diffraction on the target phases. Successful doping of the samples was confirmed by X-ray photoelectron spectroscopy and energy dispersive X-ray analysis. Thermopower values of the samples are found to be relatively high in analogy to semiconducting behavior in which negative values indicate electrons are the dominant charge carriers (n-type). Substitution of Zn2+ by Ga3+ and In3+ for Zn1−x−y Al x Me y O (Me: Ga, In) increases electron concentration in the samples and thereby decreases the thermopower values compared to Zn0.98Al0.02O. Considering the absolute values, In doped samples have higher thermopower (α max = −162 µV/K at 585 °C for Zn0.96Al0.02In0.02O) compared to the Ga doped sample. Al and In dually doped Zn0.96Al0.02In0.02O could be considered as a promising n-type thermoelectric material for high temperature applications.

Similar content being viewed by others

References

L. Liu, Int. J. Eng. Sci. 55, 35–53 (2012)

R. Kim, M.S. Lundstrom, J. Appl. Phys. 110(3), 034511 (2011)

M.S. Dresselhaus, G. Chen, Z.F. Ren, G. Dresselhaus, A. Henry, J.-P. Fleurial, JOM 61(4), 86–90 (2009)

F. Zhang, B. Niu, K. Zhang, X. Zhang, Q. Lu, J. Zhang, J. Rare Earths 31(9), 885–890 (2013)

K. Park, H.K. Hwang, J.W. Seo, W.S. Seo, Energy 54, 139–145 (2013)

G.J. Snyder, E.S. Toberer, Nat. Mater. 7(2), 105–114 (2008)

M.H. Elsheikh, D.A. Shnawah, M.F.M. Sabri, S.B.M. Said, M.H. Hassan, M.B. Ali Bashir, M. Mohamad, Renew Sustain Energy Rev. 30, 337–355 (2014)

S. Demirel, S. Altin, M.A. Aksan, J. Mater. Sci. 24(11), 4406–4410 (2013)

S. Walia, S. Balendhran, H. Nili, S. Zhuiykov, G. Rosengarten, Q.H. Wang, M. Bhaskaran, S. Sriram, M.S. Strano, K. Kalantar-zadeh, Prog. Mater. Sci. 58(8), 1443–1489 (2013)

M. Søndergaard, E.D. Bøjesen, K.A. Borup, S. Christensen, M. Christensen, B.B. Iversen, Acta Mater. 61(9), 3314–3323 (2013)

H. Alam, S. Ramakrishna, Nano Energy 2(2), 190–212 (2013)

M. Ohtaki, T. Tsubota, K. Eguchi, H. Arai, J. Appl. Phys. 79(3), 1816 (1996)

X. Qu, W. Wang, S. Lv, D. Jia, Solid State Commun. 151(4), 332–336 (2011)

L. Han, N.V. Nong, L.T. Hung, T. Holgate, N. Pryds, M. Ohtaki, S. Linderoth, J. Alloys Compd. 555, 291–296 (2013)

D. Gautam, M. Engenhorst, C. Schilling, G. Schierning, R. Schmechel, M. Winterer, J. Mater. Chem. A 3(1), 189–197 (2015)

L. Han, L.T. Hung, N. van Nong, N. Pryds, S. Linderoth, J. Electron. Mater. 42(7), 1573–1581 (2012)

D. Bérardan, C. Byl, N. Dragoe, J. Am. Ceram. Soc. 93(8), 2352–2358 (2010)

P. Jood, R.J. Mehta, Y. Zhang, G. Peleckis, X. Wang, R.W. Siegel, T. Borca-Tasciuc, S.X. Dou, G. Ramanath, Nano Lett. 11(10), 4337–4342 (2011)

T.Q. Trinh, T.T. Nguyen, D.V. Vu, D.H. Le, J. Mater. Sci. 28(1), 236–240 (2016)

M. Ohtaki, K. Araki, K. Yamamoto, J. Electron. Mater. 38(7), 1234–1238 (2009)

C. Chen, T. Zhang, R. Donelson, D. Chu, R. Tian, T.T. Tan, S. Li, Acta Mater. 63, 99–106 (2014)

H. Su, Y. Jiang, X. Lan, X. Liu, H. Zhong, D. Yu, Phys. Status Solidi A 208(1), 147–155 (2011)

J. Nan, J. Wu, Y. Deng, C.W. Nan, J. Eur. Ceram. Soc. 23, 859–863 (2003)

H.Q. Liu, X.B. Zhao, T.J. Zhu, Y. Song, F.P. Wang, Curr. Appl. Phys. 9(2), 409–413 (2009)

Y. Wang, Y. Sui, J. Cheng, X. Wang, W. Su, J. Alloys Compd. 477(1–2), 817–821 (2009)

N.N. Van, N. Pryds, Adv. Nat. Sci. 4(2), 023002 (2013)

C.-H. Lim, S.-M. Choi, W.-S. Seo, H.-H. Park, J. Electron. Mater. 41(6), 1247–1255 (2011)

M.H. Bocanegra-Bernal, J. Mater. Sci. 39, 6399–6420 (2004)

S. Demirci, S. Gültekin, S.A. Akalin, Ö. Öter, K. Ertekin, E. Çelik, Mater. Sci. Semicond. Process. 31, 611–617 (2015)

O. Culha, M.F. Ebeoglugil, I. Birlik, E. Celik, M. Toparli, J. Sol-Gel Sci. Technol. 51(1), 32–41 (2009)

K.A. Borup, J. de Boor, H. Wang, F. Drymiotis, F. Gascoin, X. Shi, L. Chen, M.I. Fedorov, E. Müller, B.B. Iversen, G.J. Snyder, Energy Environ. Sci. 8(2), 423–435 (2015)

E. Celik, U. Aybarc, M.F. Ebeoglugil, I. Birlik, O. Culha, J. Sol-Gel Sci. Technol. 50(3), 337–347 (2009)

M. Rezaei, M. Khajenoori, B. Nematollahi, Mater. Res. Bull. 46(10), 1632–1637 (2011)

R.D. Shannon, Acta Crystallogr. Sect. A 32(5), 751–767 (1976)

P. Malliga, J. Pandiarajan, N. Prithivikumaran, K. Neyvasagam, IOSR J. Appl. Phys. 6(1), 22–28 (2014)

K. Tang, S. Gu, J. Liu, J. Ye, S. Zhu, Y. Zheng, J. Alloys Compd. 653, 643–648 (2015)

X.-K. Cai, Z.-J. Yuan, X.-M. Zhu, X. Wang, B.-P. Zhang, D.-J. Qiu, H.-Z. Wu, Chin. Phys. B 20(10), 106103 (2011)

Acknowledgements

This work was supported by the Scientific and Technological Research Council of Turkey (TUBITAK) under Project No. 115M579. We would like to thank to Dr. Umut Aydemir and Prof. G. J. Snyder at Northwestern University in Evanston, IL, USA for thermopower measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kilinc, E., Demirci, S., Uysal, F. et al. High temperature thermopower of sol–gel processed Zn1−x−y Al x Me y O (Me: Ga, In). J Mater Sci: Mater Electron 28, 11769–11778 (2017). https://doi.org/10.1007/s10854-017-6982-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-6982-7