Abstract

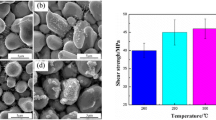

In order to investigate the effects of alloying Cu substrate on microstructure and coarsening behavior of Cu6Sn5 grains of soldered joints, in the paper, four types of wetting layers (Cu, Cu–8 wt% Zn, Cu–15 wt% Zn and Cu–30 wt% Zn) reaction with Sn–3.0Ag–0.5Cu (SAC305) solder were fabricated. The effects of reflowing and isothermal aging on the interface of soldered joints and the morphology of Cu6Sn5 grains were studied. Experimental results show that the scallop-shaped Cu6Sn5 formed at the interface of SAC/Cu after reflowing. After isothermal aging for 120 h, a bi-layer structure of Cu6Sn5 and Cu3Sn formed at the interface of SAC/Cu and some Ag3Sn grains decorated in Cu6Sn5, and Kirkendall voids were observed inside the Cu3Sn layer after aging for 240 h. However, Cu6Sn5 was the predominant reaction product and Cu3Sn and Kirkendall voids were not observed at the interface of SAC/Cu–Zn irrespective of aging time. The thickness of IMC layer increases with increasing aging time. Compared to SAC/Cu, the additions of Zn can effectively suppress the growth of IMC. During the aging process, the growth rate constants of IMC layers of SAC/Cu, SAC/Cu–8Zn, SAC/Cu–15Zn and SAC/Cu–30Zn were obtained by using fitting method from the experimental data, which were 7.78 × 10−17, 5.42 × 10−17, 2.51 × 10−17 and 1.46 × 10−17 m2 s−1, respectively. The mean diameter of IMC grains increases with the increasing aging time. The relationships of the mean diameter of Cu6Sn5 grains of SAC/Cu, SAC/Cu–8Zn, SAC/Cu–15Zn, SAC/Cu–30Zn interface joints and aging time were given, i.e., d = 1.49t 0.237, d = 1.46t 0.204, d = 1.43t 0.203 and d = 1.71t 0.197, respectively.

Similar content being viewed by others

References

T. Laurila, V. Vuorinen, J.K. Kivilahti, Mater. Sci. Eng., R 49, 1–60 (2005)

J.X. Wang, H. Nishikawa, Microelectron. Reliab. 54, 1583–1591 (2014)

J.-H. Kim, Y.-C. Lee, S.-M. Lee et al., Microelectron. Eng. 120, 77–84 (2014)

Y. Kim, T. Kim, M. Choi et al., J. Alloys Compd. 575, 350–358 (2013)

L.C. Tsao, J Alloys Compd 509, 8441–8448 (2011)

W.-L. Chen, Yu. Chi-Yang, C.-Y. Ho, J.-G. Duh, Mater. Sci. Eng., A 613(1), 93–200 (2014)

M. Maleki, J. Cugnoni, J. Botsis, Acta Mater. 61, 103–114 (2013)

J. Shen, M. Zhao et al., J Alloys Compd 574, 451–458 (2013)

A.A. El-Daly, A.E. Hammad, G.S. Al-Ganainy et al., Mater. Sci. Eng., A 608, 130–138 (2014)

A.A. El-Daly, A.E. Hammad, G.S. Al-Ganainy et al., J Alloys Compd 614, 20–28 (2014)

H.R. Kotadia, O. Mokhtari, M.P. Clode et al., J Alloys Compd 511, 176–188 (2012)

Yu. Chi-Yang, J.-G. Duh, Scr Mater 65, 783–786 (2011)

Y.U. Chi-Yang, W.A.N.G. Kai-Jheng, D.U.H. Jenq-Gong, J. Electron. Mater. 39(2), 230–238 (2010)

H.F. Zou, Q.K. Zhang, Z.F. Zhang, Scr Mater 61, 308–311 (2009)

C.-C. Fu, C.-c. Chen, J. Chin. Inst. Chem. Eng. 42, 350–355 (2011)

J. Lee, Y. Kim, J. Hwang et al., J Alloys Compd 567, 10–14 (2013)

T.-C. Liu, C.-M. Liu, Y.-S. Huang et al., Scr Mater 68, 241–244 (2013)

X. Hu, Z. Ke, J. Mater. Sci.: Mater. Electron. 25, 936–945 (2014)

A.A. El-Daly, A.M. El-Taher, Mater. Des. 51, 789–796 (2013)

M. Yang, M. Li, J. Kim, Intermetallics 31, 177–185 (2012)

X. Yu, X.W. Hu, Y.L. Li et al., J. Mater. Sci.: Mater. Electron. 25, 2416–2425 (2014)

Yu. Chi-Yang, Wei.-Yu. Chen, J.-G. Duh, J Alloys Compd 586, 633–638 (2014)

W. Peng, E. Monlevade, M. Marques, Microelectron. Reliab. 47, 2161–2168 (2007)

H. Xiaowu, Y. Li, Z. Min, J Alloys Compd 582, 341–347 (2014)

J.W. Jang, P.G. Kim, K.N. Tu, D.R. Frear, P. Thompson, J. Appl. Phys. 85, 8456–8463 (1999)

K. Jung, H. Conrad, J. Electron. Mater. 30, 1308–1312 (2001)

D. G. Kim, S. B. Jung, J. Alloys Compd. 386, 151–156 (2005)

X. Hu, S. Xu, Y. Yang, Z. Chen, Y.C. Chan, Mater. Sci. Eng., A 600, 67–75 (2014)

H.K. Kim, K.N. Tu, Phys Rev B 53(23), 593–596 (1996)

H.F. Zou, H.J. Yang, Z.F. Zhang, Mater. Chem. Phys. 131, 190–198 (2011)

Acknowledgments

This work was supported by the Nature Science Foundation of China (No. 51465039) and the Science and Technology project of Jiangxi Department of Education (GJJ14108).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, X., Hu, X., Li, Y. et al. Effect of alloying Cu substrate on microstructure and coarsening behavior of Cu6Sn5 grains of soldered joints. J Mater Sci: Mater Electron 26, 2782–2794 (2015). https://doi.org/10.1007/s10854-015-2759-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-2759-z