Abstract

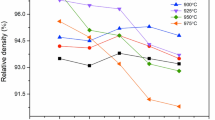

Microwave dielectric ceramics in the Ba0.2Sr0.8La4Ti4+xO15 composition series were prepared through a solid state mixed oxide route. The stoichiometric Ba0.2Sr0.8La4Ti4O15 ceramics can be well densified in the temperature of 1,450 °C with a high compact microstructure. The phase composition was found to be sensitive to nonstoichiometry of TiO2 in this system because the major crystal phase of excess TiO2 samples was transformed from SrLa4Ti4O15 to La2TiO5. As the amount of TiO2 increased, the εr value of the Ba0.2Sr0.8La4Ti4+xO15 ceramics increased sharply first, and then showed a slightly decline after reaching the maximum value at x = 0.10, the Q × f value decreased almost linearly from 62,800 to 36,100 GHz, while the τf value varied gradually toward positive direction from −20.0 to −2.6 ppm/°C. Optimum dielectric properties were achieved for stoichiometric Ba0.2Sr0.8La4Ti4O15 and nonstoichiometric Ba0.2Sr0.8La4Ti4.20O15 ceramics which exhibited an excellent Q × f value and a near zero τf value with other considerable microwave dielectric properties, respectively.

Similar content being viewed by others

References

C.-H. Hsu, C.-J. Huang, J. Alloy. Compd. 587, 45–49 (2014)

Y. Tohdo, K. Kakimoto, H. Ohsato et al., J. Eur. Ceram. Soc. 26, 2039–2043 (2006)

X. Wang, Y. Li, J. Li et al., J. Mater. Sci.: Mater. Electron. 25, 4720–4724 (2014)

W. Chi, K.A. Zaki, IEEE Microw. Mag. 8, 115–127 (2007)

R.R. Mansour, IEEE Microw. Mag. 5, 68–74 (2004)

H. Sreemoolanadhan, J. Isaac, S. Solomon et al., Physica Status Solidi (A) 143, K45–K48 (1994)

R. Ratheesh, H. Sreemoolanadhan, M.T. Sebastian, J. Solid State Chem. 131, 2–8 (1997)

B. Tang, S. Yu, H. Chen et al., J. Mater. Sci.: Mater. Electron. 24, 1475–1479 (2013)

S.Q. Yu, B. Tang, X. Zhang et al., J. Am. Ceram. Soc. 95, 1939–1943 (2012)

Y. Iqbal, A. Manan, I.M. Reaney, Mater. Res. Bull. 46, 1092–1096 (2011)

I.N. Jawahar, N.I. Santha, M.T. Sebastian et al., J. Mater. Res. 17, 3084–3089 (2002)

O. Takashi, K. Katsumasa, O. Hiroki et al., Jpn. J. Appl. Phys. 40, 5779–5782 (2001)

J. Pei, Z. Yue, F. Zhao et al., J. Alloy. Compd. 459, 390–394 (2008)

L. Liu, Y.-W. Fang, X.-F. Deng et al., J. Inorg. Mater. 27, 281–284 (2012)

B. Tang, H. Li, P. Fan et al., J. Mater. Sci: Mater. Electron. 25, 1–5 (2014)

A. Templeton, X. Wang, S.J. Penn et al., J. Am. Ceram. Soc. 83, 95–100 (2000)

Y.-C. Liou, Y.-T. Chen, W.-C. Tsai, J. Alloy. Compd. 477, 537–542 (2009)

Y. Li, J. Li, B. Tang et al., J. Mater. Sci.: Mater. Electron. 25, 1–6 (2014)

Z.G. Zang, Appl. Opt. 52, 5701–5706 (2013)

Z.G. Zang, W.X. Yang, J. Appl. Phys. 109, 103–106 (2011)

Z.G. Zang, Y.J. Zhang, J. Mod. Opt. 59, 161–165 (2012)

R. Shannon, Acta Crystallogr. Sect. A 32, 751–767 (1976)

X. Diez-Betriu, J.E. Garcia, C. Ostos et al., Mater. Chem. Phys. 125, 493–499 (2011)

Z. Yue, F. Zhao, Z. Gui et al., J. Alloy. Compd. 395, 126–131 (2005)

M.A. Petrova, R.G. Grebenshchikov, Glass Phys. Chem. 34, 603–607 (2008)

M. German, L.M. Kovba, Russ. J. Inorg. Chem. 28, 2377–2379 (1983)

S.D. Skapin, D. Kolar, D. Suvorov, J. Eur. Ceram. Soc. 20, 1179–1185 (2000)

T. Junichi, K. Keisuke, K. Kouhei, Jpn. J. Appl. Phys. 32, 4327–4331 (1993)

J.B. MacChesney, H.A. Sauer, J. Am. Ceram. Soc. 45, 416–422 (1962)

Z. Li, W. Wu, F. Liu et al., Mater. Lett. 118, 24–26 (2014)

T.A. Vanderah, V.L. Miller, I. Levin et al., J. Solid State Chem. 177, 2023–2038 (2004)

H. Li, Y. Li, B. Tang et al., J. Mater. Sci.: Mater. Electron. 25, 717–722 (2014)

M.P. Seabra, A.N. Salak, M. Avdeev et al., J. Phys. Condens. Matter. 15, 8 (2003)

N. Teneze, D. Mercurio, G. Trolliard et al., Mater. Res. Bull. 35, 1603–1614 (2000)

H.X. Lin, Y. Zhang, X.Y. Zhao et al., Jpn. J. Appl. Phys. 47, 7243–7245 (2008)

Acknowledgments

This work is supported by National Natural Science Funds of China (Grant No. 51402039).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, B., Si, F., Li, Yx. et al. Preparation and characterization of Ba0.2Sr0.8La4Ti4+xO15 microwave dielectric ceramics. J Mater Sci: Mater Electron 26, 2719–2725 (2015). https://doi.org/10.1007/s10854-015-2748-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-2748-2