Abstract

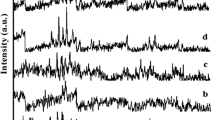

In an attempt to obtain the best possible properties of barium hexaferrite (BaFe12O19), the sol–gel synthesis method was chosen and, the optimum sintering conditions were established. The effects of the sintering temperature on the structural, morphological and magnetic properties of hexaferrite were studied. X-ray analysis indicates that the sintered samples (1,000–1,150 °C) remained in the hexagonal structure. From this analysis, no secondary phases are identified. The effect of sintering temperature on the grain growth of BaFeBaFe12O19 is confirmed by the microstructure using HR-SEM and is in good agreement with the XRD analysis based on the peak intensity of the (107) plane. The samples sintered at 1,150 °C showed the densities as ~93 % of theoretical density. Sintering temperature affected the grains in compact samples. The results show that homogeneous and dense BaFeBaFe12O19 ceramics obtained at a lower sintering temperature of 1,150 °C which is lower than the normally reported sintering temperature of ≥1,200 °C. The thermal treatment can markedly affect the grains in compact samples.

Similar content being viewed by others

References

X. Liu, J. Wang, L.M. Gan, S.C. Ng, J. Magn. Magn. Mater. 195, 452 (1999)

F.M.M. Pereira, M.R.P. Santos, R.S.T.M. Sohn, J.S. Almeida, A.M.L. Medeiros, M.M. Costa, A.S.B. Sombra, J. Mater. Sci. Mater. Electron. 20, 408 (2009)

K. Ogrady, H. Laidler, J. Magn. Magn. Mater. 200, 616 (1999)

R.C. Buchanan, Ceramic Materials for Electronics, 2nd edn. (Marcel Dekker Inc., New York, 1991), pp. 207–210

V. Babu, P. Padaikathan, J. Magn. Magn. Mater. 241, 85 (2002)

Y. Bai, J. Zhou, Z. Gui, Z. Yue, L. Li, Mater. Sci. Eng. B 99, 266 (2003)

V.K. Sankaranarayanan, R.P. Pant, A.C. Rastogi, J. Magn. Magn. Mater. 220, 72 (2000)

C.Y. Tsay, K.S. Liu, T.F. Lin, I.N. Lin, J. Magn. Magn. Mater. 209, 189 (2000)

A. Gonchar, S. Gorelik, S. Katynkina, L. Letyuk, I. Ryabov, J. Magn. Magn. Mater. 215, 221 (2000)

J. Huang, H. Zhuang, W. Li, Mater. Res. Bull. 38, 149 (2003)

L.L. Hench, J.K. West, Principles of Electronic Ceramics (Wiley, New York, 1990), pp. 305–309

O. Kubo, T. Ido, H. Yokoyama, IEEE Trans. Magn. 18, 1122 (1982)

X.X. Liu, J.M. Bai, F.L. Wei, Z. Yang, A. Morisako, M. Matsunori, J. Magn. Magn. Mater. 212, 273 (2000)

S. Besenicar, M. Drofenik, D. Kolar, Proc. ICF 5, 163 (1989)

W.D. Kingery, Introduction to Ceramics, 2nd edn. (Wiley, New Jersey, 1976), pp. 516–580

P. Sharma, R.A. Rocha, S.N. de Medeiros, A. Paesano Jr, J. Alloys Compd. 443, 37 (2007)

X.F. Yang, Q.L. Li, J.X. Zhao, B.D. Li, Y.F. Wang, J. Alloys Compd. 475, 312 (2009)

H. Kumazawa, H.M. Cho, E. Sada, J. Mater. Sci. 28, 5247 (1993)

R.C. Pullar, M.D. Taylor, A.K. Bhattacharya, J. Mater. Sci. 32, 349 (1997)

K.K. Mallick, P. Shepherd, R.J. Green, J. Euro. Ceram. Soc. 27, 2045 (2007)

A. Ataie, S. Heshmatimanesh, H. Kazempour, J. Mater. Sci. 37, 2125 (2002)

S. Kanagesan, S. Jesurani, R. Velmurugan, S. Prabu, T. Kalaivani, J. Mater. Sci. Mater. Electron. 23, 1127 (2012)

W. Zhong, W. Ding, Y. Jiang, J. Zhang, Y. Du, Q. Yan, J. Am. Ceram. Soc. 80, 3258 (1997)

R.S. Azis, M. Hashim, N. Yahya, R. Alias, N.M. Saiden, N.A. Aini, A.A. Rejab, Z. Hari, Proc. Seminar Kimia Bersama UKM-ITB Ke 5, 169 (2002)

K. Haneda, H. Kojima, J. Appl. Phys. 44, 3760 (1973)

C. Sudakar, G.N. Subbanna, T.R.N. Kutty, J. Electroceram. 6, 123 (2001)

J. Dho, E.K. Lee, J.Y. Park, N.H. Hur, J. Magn. Magn. Mater. 285, 164 (2005)

Y.F. Lu, W.D. Song, Appl. Phys. Lett. 76, 490 (2000)

P. Ren, J.G. Guan, X.D. Cheng, Mater. Chem. Phys. 98, 90 (2006)

G. Mendoza-Suarez, J.A. Matutes-Aquino, J.I. Escalante-Garcia, H. Mancha-Molinar, D. Ros-Jara, K.K. Johal, J. Magn. Magn. Mater. 223, 55 (2001)

S.R. Janasi, M. Emura, F.J.G. Landgraf, D. Rodrigues, J. Magn. Magn. Mater. 238, 168 (2002)

Acknowledgments

The authors thank SRM University for providing the facilities available in Nanotechnology center and ITMA, Universiti Putra Malaysia for the pre-submission final editing of this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kanagesan, S., Hashim, M., Kalaivani, T. et al. Sintering temperature dependence of optimized microstructure formation of BaFe12O19 using sol–gel method. J Mater Sci: Mater Electron 26, 1363–1367 (2015). https://doi.org/10.1007/s10854-014-2547-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-2547-1