Abstract

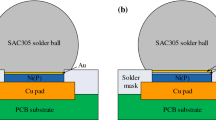

Co–P films with P contents of 4.0 and 8.0 at.% were electroplated on printed circuit boards and used as surface finish of ball grid array (BGA) packages. Sn–3.0 wt% Ag–0.5 wt% Cu (SAC305) solder balls were reflowed on the Co–P finish to form SAC/Co–P solder joints. The morphology and growth of intermetallic compounds (IMCs) in SAC/Co–P joints under thermal cycling were systematically analyzed, and the effects of IMCs on shear strength and fractured surface of the joints were studied. SAC/Cu BGA solder joints were also prepared as a comparison. It was found that CoSn3 and (Cu, Co)6Sn5 grew at the interface of SAC/Co–4 at.% P solder joints during thermal cycling. The shear strength of SAC/Co–4 at.% P joints exceeded that of SAC/Cu joints after 100 thermal cycles, because the granule size of (Cu, Co)6Sn5 was smaller than that of Cu6Sn5 and no Kirkendall void existed at the interface of SAC/Co–4 at.% P joints. For SAC/Co–8 at.% P joints, a layer of smooth and void-free Co–Sn–P formed at the interface, and the shear strength of SAC/Co–8 at.% P joints increased by 8.4 % in comparison with that of SAC/Cu joints after 300 cycles. In addition, the fractured surface of three kinds of joints after thermal cycling was examined. The experimental data demonstrated that Co–P surface finish enhanced the shear strength of solder joints after thermal cycling and improved the reliability of BGA packages.

Similar content being viewed by others

References

A.E. Hammad, Mater. Design 52, 663 (2013)

L. Zhang, C. He, Y. Guo, J. Han, Y. Zhang, X. Wang, Microelectron. Reliab. 52, 559 (2012)

J.K. Han, D. Choi, M. Fujiyoshi, N. Chiwata, K. Tu, Acta Mater. 60, 102 (2012)

R. Zhang, F. Guo, J. Liu, H. Shen, F. Tai, J. Electron. Mater. 38, 241 (2009)

R. Zhang, J. Cai, Q. Wang, J. Li, Y. Hu, D. Du, L. Li, J. Electron. Packag. 136, 011012 (2014)

J.H. Hong, H.Y. Lee, A.T. Wu, J. Alloys Compd. 580, 195 (2013)

C. Kuo, H. Hua, H. Chan, T. Yang, K. Lin, C. Ho, Microelectron. Reliab. 53, 2012 (2013)

C. Lin, C. Chen, Microelectron. Reliab. 52, 385 (2012)

C. Tseng, T. Lee, G. Ramakrishna, K. Liu, J. Duh, Mater. Lett. 65, 3216 (2011)

T.H. Chuang, C.C. Jain, H.M. Wu, J. Electron. Mater. 37, 1734 (2008)

C.E. Ho, C.W. Fan, W.H. Wu, T.T. Kuo, Thin Solid Films 529, 364 (2013)

T.J. Kim, Y.M. Kim, Y. Kim, J. Alloys Compd. 535, 33 (2012)

P. Chia, A.S.M. Haseeb, J. Mater. Sci. Mater. Electron. 24, 3423 (2013)

A. Sharif, Y.C. Chan, J. Mater. Sci. Mater. Electron. 16, 153 (2005)

T. Lee, B. Zhou, L. Blair, K. Liu, T. Bieler, J. Electron. Mater. 39, 2588 (2010)

T. Lee, B. Zhou, T. Bieler, K. Liu, J. Electron. Mater. 41, 273 (2012)

J. Pang, L. Xu, X. Shi, W. Zhou, S. Ngoh, J. Electron. Mater. 33, 1219 (2004)

H.R. Kotadia, O. Mokhtari, M. Bottrill, M.P. Clode, M.A. Green, S.H. Mannan, J. Electron. Mater. 39, 2720 (2010)

C. Chen, Y. Chan, Y. Chen, J. Mater. Res. 25, 1321 (2010)

F. Guo, J. Mater. Sci. Mater. Electron. 18, 129 (2007)

I. Anderson, J. Mater. Sci. Mater. Electron. 18, 55 (2007)

N. Lu, D. Yang, L. Li, Acta Mater. 61, 4581 (2013)

S. Xu, X. Hu, Y. Yang, Z. Chen, Y. Chan, J. Mater. Sci. Mater. Electron. 25, 2682 (2014)

T. An, F. Qin, Microelectron. Reliab. 54, 932 (2014)

F. Gao, T. Takemoto, H. Nishikawa, A. Komatsu, J. Electron. Mater. 35, 905 (2006)

J. Shen, Y.C. Chan, S.Y. Liu, Acta Mater. 57, 5196 (2009)

M. Wu, X. He, Rafi-ud-din, S. Ren, M. Qin, X. Qu, Mater. Chem. Phys. 121, 259 (2010)

J.F. Li, S.H. Mannan, M.P. Clode, K. Chen, D.C. Whalley, C. Liu, D.A. Hutt, Acta Mater. 55, 737 (2007)

C.E. Ho, S.C. Yang, C.R. Kao, J. Mater. Sci. Mater. Electron. 18, 155 (2007)

R. Labie, E. Beyne, R. Mertens, P. Ratchev, J. Van Humbeeck, in Proceeding of 5th Electronics Packaging Technology Conference (EPTC 2003), p. 584 (2003)

K.C. Huang, F.S. Shieu, T.S. Huang, C.T. Lu, C.W. Chen, H.W. Tseng, S.L. Cheng, C.Y. Liu, J. Electron. Mater. 39, 2403 (2010)

M. Liang, H. Yen, T. Hsieh, J. Electron. Mater. 35, 1593 (2006)

H. Pan, T. Hsieh, J. Electrochem. Soc. 158, 123 (2011)

D. Yang, N. Lu, L. Li, in Proceeding of 63rd Electronic Components and Technology Conference (ECTC 2013), p. 1686 (2013)

A. Kumar, A. Singh, M. Kumar, D. Kumar, S. Barthwal, J. Mater. Sci. Mater. Electron. 22, 1495 (2011)

Y. Yang, J.N. Balaraju, Y. Huang, H. Liu, Z. Chen, Acta Mater. 71, 69 (2014)

D. Yang, G. Yang, J. Cai, Q. Wang, Y. Hu, J. Li, L. Li, in Proceeding of 15th International Conference on Electronic Packaging Technology (ICEPT 2014), p. 239 (2014)

N. Lu, J. Cai, L. Li, Surf. Coat. Technol. 206, 4822 (2012)

J.F. Li, P.A. Agyakwa, C.M. Johnson, Acta Mater. 59, 1198 (2011)

W.K. Choi, H.M. Lee, J. Electron. Mater. 29, 1207 (2000)

K.H. Prakash, T. Sritharan, Acta Mater. 49, 2481 (2001)

M.S. Park, R. Arróyave, Acta Mater. 58, 4900 (2010)

C. Yu, Y. Yang, K. Wang, J. Xu, J. Chen, H. Lu, J. Mater. Sci. Mater. Electron. 23, 124 (2012)

Y. Ding, C. Wang, Y. Tian, M. Li, J. Alloys Compd. 428, 274 (2007)

F. Lin, W. Bi, G. Ju, W. Wang, X. Wei, J. Alloys Compd. 509, 6666 (2011)

Acknowledgments

This work was supported by the National Science and Technology Major Project of the Ministry of Science and Technology of China (Grant No. 2011ZX02601), China Postdoctoral Science Foundation (Grant No. 2013M540937), Tsinghua University Initiative Scientific Research Program (Grant No. 20111080957), and the Scientific Research Foundation for Returned Overseas Chinese Scholars, State Education Ministry.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, D., Cai, J., Wang, Q. et al. IMC growth and shear strength of Sn–Ag–Cu/Co–P ball grid array solder joints under thermal cycling. J Mater Sci: Mater Electron 26, 962–969 (2015). https://doi.org/10.1007/s10854-014-2489-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-2489-7