Abstract

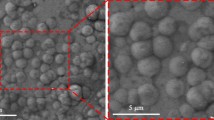

The size (volume) effect of solder balls on the interfacial reactions of Sn–3.0Ag–0.5Cu solders on both Cu and Ni–P pads in electronic packaging was systematically investigated. For the interfacial reaction on Cu pad, the smaller the solder ball is, the larger the interfacial Cu6Sn5 grains are, the thicker the intermetallic compound (IMC) layer is, and the less the Cu pad consumption is. The Cu concentration approached the solution saturation more rapidly in the smaller solder joints through grain boundary diffusion, resulting in smaller Cu outflux at the interface and consequently coarser interfacial Cu6Sn5 grains. For the interfacial reaction on Ni–P pad, the smaller the solder ball is, the earlier the transformation of interfacial IMCs from (Cu,Ni)6Sn5 to (Ni,Cu)3Sn4 occurs. The faster decreasing rate of Cu concentration in smaller molten solder resulted in the less supplying Cu influx and thus the earlier IMC transition. The Cu flux at the interface determines the growth kinetics and the phase transformation of interfacial IMCs on both Cu and Ni–P pads. Accordingly, the variation of Cu fluxes at the interface caused by solder ball volume results in the size effect.

Similar content being viewed by others

References

H.Y. Hsiao, C.M. Liu, H.W. Lin, T.C. Liu, C.L. Lu, Y.S. Huang, C. Chen, K.N. Tu, Science 336, 1007 (2012)

A. Sharif, Y.C. Chan, R.A. Islam, Mater. Sci. Eng. B 106, 120 (2004)

P. Zimprich, A. Betzwar-Kotas, G. Khatibi, B. Weiss, H. Ipser, J. Mater. Sci. Mater. Electron. 19, 383 (2008)

L.M. Yin, S. Wei, Z.L. Xu, Y.F. Geng, J. Mater. Sci. Mater. Electron. 24, 1369 (2013)

X.M. Li, F.L. Sun, Y. Liu, H. Zhang, T. Xin, J. Mater. Sci. Mater. Electron. 25, 3742 (2014)

M.N. Islam, A. Sharif, Y.C. Chan, J. Electron. Mater. 34, 143 (2005)

C.C. Chang, Y.W. Lin, Y.W. Wang, C.R. Kao, J. Alloys Compd. 492, 99 (2010)

L.W. Liu, M.L. Huang, in 11th international conference on electronic packaging technology & high density packaging (IEEE, Shanghai, 2010), pp. 299–304

C.E. Ho, Y.W. Lin, S.C. Yang, C.R. Kao, D.S. Jiang, J. Electron. Mater. 35, 1017 (2006)

Y.S. Park, Y.M. Kwon, J.T. Moon, Y.W. Lee, J.H. Lee, K.W. Paik, in Proceedings of the 60th electronic components and technology conference (IEEE, Nevada, 2010), pp. 1436–1441

H.K. Kim, H.K. Liou, K.N. Tu, Appl. Phys. Lett. 66, 2337 (1995)

H.K. Kim, K.N. Tu, Phys. Rev. B 53, 16027 (1996)

M.L. Huang, T. Loeher, A. Ostmann, H. Reichl, Appl. Phys. Lett. 86, 181908 (2005)

F. Yang, M.L. Huang, N. Zhao, in 13th international conference on electronic packaging technology and high density packaging (IEEE, Guilin, 2012), pp. 499–502

J.W. Yoon, S.W. Kim, S.B. Jung, J. Alloys Compd. 415, 56 (2006)

K.W. Moon, W.J. Boettinger, U.R. Kattner, F.S. Biancaniello, C.A. Handwerker, J. Electron. Mater. 29, 1122 (2000)

C.E. Ho, R.Y. Tsai, Y.L. Lin, C.R. Kao, J. Electron. Mater. 31, 584 (2002)

Y.D. Jeon, K.W. Paik, A. Ostmann, H. Reichl, J. Electron. Mater. 34, 80 (2005)

H.P.R. Frederikse, R.J. Fields, A. Feldman, J. Appl. Phys. 72, 2879 (1992)

W.M. Chen, S.C. Yang, M.H. Tsai, C.R. Kao, Scr. Metall 63, 47 (2010)

Acknowledgments

This work is supported by the National Natural Science Foundation of China under Grant Nos. 51475072 and 51171036.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, M.L., Yang, F. Size effect on interfacial reactions of Sn–3.0Ag–0.5Cu solder balls on Cu and Ni–P pads. J Mater Sci: Mater Electron 26, 933–942 (2015). https://doi.org/10.1007/s10854-014-2485-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-2485-y