Abstract

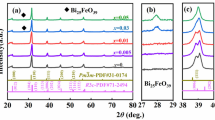

Development of high-temperature piezoelectric sensors is of great interest for harsh environment applications. The principal challenge for piezoelectric materials is their limitation for upper working temperature due to low Curie temperature and increasing conductivity at high temperatures. The effects of SiO2 addition on the microstructure, ferro-piezoelectric and thermal stability of 0.8BiFeO3–0.2BaTiO3 lead-free piezoelectric ceramics were investigated. XRD results indicated all the samples crystallized into the rhombohedrally distorted perovskite structure which was independent of the SiO2 addition. SiO2 could obviously inhibit the grain growth possibly due to the accumulation of SiO2 at the grain boundary. The leakage currents of 0.8BiFeO3–0.2BaTiO3 piezoceramics were remarkably reduced by certain amounts of added SiO2, facilitating the poling process, and improved their piezoelectric properties effectively. The optimal properties were obtained at the composition with 0.15 wt% SiO2 addition which retained high transition temperature ~628 °C. The samples sintered in O2 exhibited better thermal stability than those sintered in reduced atmospheres. Thus, SiO2 proved to be a successful additive to improve the 0.8BiFeO3–0.2BaTiO3 piezoceramics for high-temperature applications, as a result of increased resistivity and enhanced piezoelectric activity.

Similar content being viewed by others

References

S.J. Zhang, F.P. Yu, J. Am. Ceram. Soc. 94, 3153 (2011)

Q. Zhou, C.R. Zhou, H.B. Yang, G.H. Chen, W.Z. Li, H. Wang, J. Am. Ceram. Soc. 95, 3889 (2012)

R.C. Turner, P.A. Fuierer, R.E. Newnham, T.R. Shrout, Appl. Acoust. 41, 299 (1994)

S.J. Zhang, R. Xia, L. Lebrun, D. Anderson, T.R. Shrout, Mater. Lett. 59, 3471 (2005)

H. Fritze, J. Electroceram. 26, 122 (2011)

H.X. Yan, H.T. Zhang, R. Ubic, M.J. Reece, J. Liu, Z.J. Shen, Z. Zhang, Adv. Mater. 17, 1261 (2005)

H.X. Yan, H.T. Zhang, M.J. Reece, X.L. Dong, Appl. Phys. Lett. 87, 082911 (2005)

Z.H. Yao, H.X. Liu, H. Hao, M.H. Cao, J. Appl. Phys. 109, 014105 (2011)

J.B. Neaton, C. Ederer, U.V. Waghmare, N.A. Spaldin, K.M. Rabe, Phys. Rev. B 71, 014113 (2005)

P. Ravindran, R. Vidya, A. Kjekshus, H. Fjellvag, O. Eriksson, Phys. Rev. B 74, 224412 (2006)

M. Kumar, K.L. Yadav, Appl. Phys. Lett. 91, 112911 (2007)

Y.P. Wang, L. Zhou, M.F. Zhang, X.Y. Chen, J.M. Liu, Z.G. Liu, Appl. Phys. Lett. 84, 1731 (2004)

C. Guo, S. Pu, Z.L. Chen, M.Y. Li, J.F. Cao, H.M. Zou, Ceram. Int. 36, 507 (2010)

G.L. Yuan, S.W. Or, Y.P. Wang, Z.G. Liu, J.M. Liu, Solid State Commun. 138, 76 (2006)

S.O. Leontsev, R.E. Eitel, J. Am. Ceram. Soc. 92, 2957 (2009)

H. Uchida, R. Ueno, H. Funakubo, S. Koda, J. Appl. Phys. 100, 014106 (2006)

A. Kumar, D. Varshney, Ceram. Int. 38, 3935 (2012)

F. Yan, M.O. Lai, L. Lu, J. Phys. D Appl. Phys. 45, 325001 (2012)

H.R. Liu, Y.X. Sun, J. Phys. D Appl. Phys. 40, 7530 (2007)

Y.K. Jun, W.T. Moon, C.M. Chang, H.S. Kim, H.S. Ryu, J.W. Kim, K.H. Kim, S.H. Hong, Solid State Commun. 135, 133 (2005)

Z. Hu, M. Li, B. Yu, L. Pei, J. Liu, J. Wang, X. Zhao, J. Phys. D Appl. Phys. 42, 185010 (2009)

M.T. Buscaglia, L. Mitoseriu, V. Buscaglia, I. Pallecchi, M. Viviani, P. Nanni, A.S. Siri, J. Eur. Ceram. Soc. 26, 3027 (2006)

M.M. Kumar, A. Srinivas, S.V. Suryanarayana, J. Appl. Phys. 87, 855 (2000)

Q.Q. Wang, Z. Wang, X.Q. Liu, X.M. Chen, J. Am. Ceram. Soc. 95, 670 (2012)

R.T. Smith, G.D. Achenbach, R. Gerson, W.J. James, J. Appl. Phys. 39, 70 (1968)

J.G. Chen, J.R. Cheng, J. Alloys Compd. 589, 115 (2014)

C.R. Zhou, H.B. Yang, Q. Zhou, G.H. Chen, W.Z. Li, H. Wang, J. Mater. Sci. Mater. Electron. 24, 1685 (2013)

L.H. Yin, B.C. Zhao, J. Fang, R.R. Zhang, X.W. Tang, W.H. Song, J.M. Dai, Y.P. Sun, J. Solid State Chem. 194, 194 (2012)

Q. Zhou, C.R. Zhou, H.B. Yang, C.L. Yuan, G.H. Chen, L. Cao, Q.L. Fan, J. Mater. Sci. Mater. Electron. 25, 196 (2014)

Y. Wan, Y. Li, Y.Q. Guo, Q.J. Zheng, X.C. Wu, C.G. Xu, D.M. Lin, J. Mater. Sci. Mater. Electron. 25, 1534 (2014)

K. Yu, Y. Niu, Y. Bai, Y. Zhou, H. Wang, Appl. Phys. Lett. 102, 102903 (2013)

K. Yu, H. Wang, Y. Zhou, Y. Bai, Y. Niu, J. Appl. Phys. 113, 034105 (2013)

W. Stöber, A. Fink, E. Bohn, J. Colloid Interface Sci. 26, 62 (1968)

X. Wang, Z. Shen, T. Sang, X. Cheng, M. Li, L. Chen, Z. Wang, J. Colloid Interface Sci. 341, 23 (2010)

T. Gholamia, M. Salavati-Niasaria, M. Bazarganipourc, E. Nooria, Superlattices Microstruct. 61, 33 (2013)

K. Tadanaga, K. Morita, K. Mori, M. Tatsumisago, J. Sol-Gel. Sci. Technol. 68, 341 (2013)

M.K. Singh, H.M. Jang, S. Ryu, M.H. Jo, Appl. Phys. Lett. 88, 042907 (2006)

M.K. Singh, S. Ryu, H.M. Jang, Phys. Rev. B 72, 132101 (2005)

H. Zhang, W. Jo, K. Wang, K.G. Webber, Ceram. Int. 40, 4759 (2014)

H.B. Yang, C.R. Zhou, X.Y. Liu, Q. Zhou, G.H. Chen, H. Wang, W. Li, Mater. Res. Bull. 47, 4233 (2012)

Y.R. Zhang, J.F. Li, B.P. Zhang, C.E. Peng, J. Appl. Phys. 103, 074109 (2008)

X.X. Wang, X.G. Tang, K.W. Kwok, H.L.W. Chan, C.L. Choy, App. Phys. A 80, 1071 (2005)

Acknowledgments

The authors would like to thank the support of the International Technology Cooperation Project from the Ministry of Science and Technology of China (2011DFA52680), Natural Science Foundation of China (Nos. 51372191 and 51102189), National Key Basic Research Program of China (No. 2015CB654601), the Fundamental Research Funds for the Central Universities (No. 2012-IV-006), and State Key Laboratory of New Ceramic and Fine Processing Tsinghua University (KF201314).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yao, Z., Xu, C., Wang, Z. et al. Microstructure, ferro-piezoelectric and thermal stability of SiO2 modified BiFeO3–BaTiO3 high temperature piezoceramics. J Mater Sci: Mater Electron 26, 479–484 (2015). https://doi.org/10.1007/s10854-014-2424-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-2424-y