Abstract

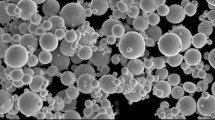

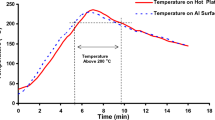

In the process of electronic packaging, such as flip chip technology, under bump metallization (UBM) can be consumed gradually by solder during soldering. Then dissolution of Ni, Au and Cu from UBM into the solder may change the original solder to a multicomponent one especially under the trend of miniaturization. It is quite necessary to evaluate the properties of the multicomponent solders that have new composition after soldering. In this study, the microstructure, thermal and mechanical properties of five types of multicomponent lead-free solders, i.e. Sn–2Cu–0.5Ni, Sn–2Cu–0.5Ni–0.5Au, Sn–3.5Ag–0.5Ni, Sn–3.5Ag–1Cu–0.5Ni and Sn–3.5Ag–2Cu–0.5Ni (all in wt% unless specified otherwise) were investigated. Comparison with eutectic Sn–0.7Cu, Sn–3.5Ag and Sn–3.5Ag–0.7Cu solders was made. There was no obvious difference of the melting point between the multicomponent lead-free solders and the eutectic ones. For Sn–2Cu–0.5Ni solder, Cu6Sn5 and (Cu,Ni)6Sn5 intermetallic compounds (IMCs) formed. In the case of Sn–2Cu–0.5Ni–0.5Au, besides (Cu,Ni)6Sn5, (Cu,Au)6Sn5 and (Cu,Ni,Au)6Sn5 were also observed. The IMCs formed in Sn–3.5Ag–0.5Ni solder were Ag3Sn and Ni3Sn4. In both Sn–3.5Ag–1Cu–0.5Ni and Sn–3.5Ag–2Cu–0.5Ni solders, Ag3Sn and (Cu,Ni)6Sn5 were detected. The mechanism for the formation of the IMCs was discussed. Tensile test was also conducted. The fractography indicated that all of the multicomponent lead-free solders exhibited a ductile rupture.

Similar content being viewed by others

References

Y. Qin, G.D. Wilcox, C.Q. Liu, J. Electrochem. Soc. 156, D424 (2009)

M.N. Islam, A. Sharif, Y.C. Chan, J. Electron. Mater. 34, 143 (2005)

M.L. Huang, Q. Zhou, N. Zhao, L.D. Chen, J. Mater. Sci.: Mater. Electron. (2013). doi:10.1007/s10854-013-1143-0

F. Zhang, M. Li, C.C. Chum, Z.C. Shao, J. Electon. Mater. 32, 123 (2003)

K. Zeng, K.N. Tu, Mater. Sci. Eng. R 38, 55 (2002)

W.M. Chen, S.C. Yang, M.H. Tsai, C.R. Kao, Scripta Mater. 63, 47 (2010)

M. Abtew, G. Selvaduray, Mater. Sci. Eng. R 27, 95 (2000)

H.Y. Hsiao, C.M. Liu, H.W. Lin, T.C. Liu, C.L. Lu, Y.S. Huang, C. Chen, K.N. Tu, Science 336, 1007 (2012)

X.H. Wang, M.L. Huang, F. Yang, N. Zhao, International Conference of Electron Package Technology and High Density Package. 823 (2012)

C.E. Ho, S.C. Yang, C.R. Kao, J. Mater. Sci. Mater. Electron. 18, 155 (2007)

C.T. Lu, T.S. Huang, C.H. Cheng, H.W. Tseng, C.Y. Liu, J. Electon. Mater. 41, 130 (2012)

D.Q. Yu, C.M.L. Wu, D.P. He, N. Zhao, L. Wang, J.K.L. Lai, J. Mater. Res. 20, 2205 (2005)

S.J. Wang, C.Y. Liu, J. Electon. Mater. 32, 1303 (2003)

N. Zhao, X.M. Pan, D.Q. Yu, H.T. Ma, L.I. Wang, J. Electon. Mater. 38, 828 (2009)

N. Zhao, X.M Pan, H.T. Ma, C. Dong, S.H. Guo, W. Lu, L. Wang, J. Phys. Conf. Ser. 98, U141 (2008)

T.B. Massalski, Binary Alloy Phase Diagrams (American Society for Metals, Metals Park, OH, 1987), pp. 315–317

N. Duan, J. Scheer, J. Bielen, M. van Kleef, Microelectron. Reliab. 43, 1317 (2003)

C.M.L. Wu, M.L. Huang, J. Electron. Mater. 31, 442 (2002)

M.L. Huang, L. Wang, C.M.L. Wu, J. Mater. Res. 17, 2897 (2002)

Acknowledgments

This work was supported by the program of the National Natural Science Foundation of China (No. 51171036), the Specialized Research Fund for the Doctoral Program of Higher Education of China (20120041120038) and the Fundamental Research Funds for the Central Universities (No. DUT11RC(3)56).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, N., Liu, X.Y., Huang, M.L. et al. Characters of multicomponent lead-free solders. J Mater Sci: Mater Electron 24, 3925–3931 (2013). https://doi.org/10.1007/s10854-013-1340-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-013-1340-x