Abstract

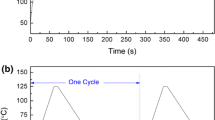

The influence of TiO2 nanoparticles on thermal property, wettability, and interfacial reaction in Sn–3.0Ag–0.5Cu–xTiO2 (x = 0, 0.05, 0.1, and 0.6) lead-free composite solder was investigated in this study. Results show that the solidus temperatures of the TiO2-containing composite solder have no obvious change compared with TiO2-free solder. However, the liquidus temperatures of the TiO2-containing composite solders increase by 4.4 °C with an increase in amounts of TiO2 nanoparticles. The wetting angle of the composite solder decreases with the addition of TiO2 nanoparticles ranging from 0.05 to 0.1 wt%, while the spreading area increases. Based on the spherical cap model, the mathematical relation between the wetting angle and spreading area is analyzed. Scanning electron microscopy was used to observe the interfacial microstructure evolution of solder joints and to estimate the thickness of the intermetallic layer. Energy dispersive x-ray and x-ray diffractometry were used to identify the intermetallic compound (IMC) phases. Results reveal that both the thickness of IMCs and the size of Cu6Sn5 grains formed in the solder matrix decrease when TiO2 nanoparticles were added. It was also observed that some of the TiO2 nanoparticles are adsorbed on the surfaces of the scallop-like Cu6Sn5 grains. According to the adsorption theory, the surface energy of the Cu6Sn5 grains decreases with adsorption of TiO2 nanoparticles. Therefore, the diffusion of Sn and Cu atoms might be retarded, resulting in suppressing the growth of the IMCs layer.

Similar content being viewed by others

References

G.Y. Li, X.D. Bi, Q. Chen, X.Q. Shi, J. Electron. Mater. 40, 165 (2011)

G. Zeng, S.B. Xue, L. Zhang, L.L. Gao, W. Dai, J.D. Luo, J. Mater. Sci.: Mater. Electron. 21, 421 (2010)

X.P. Zhang, L.M. Yin, C.B. Yu, J. Mater. Sci.: Mater. Electron. 19, 393 (2008)

L.C. Tsao, S.Y. Chang, C.I. Lee, W.H. Sun, C.H. Huang, Mater. Des. 31, 4831 (2010)

Y.D. Han, H.Y. Jing, S.M.L. Nai, L.Y. Xu, C.M. Tan, J. Wei, J. Mater. Sci.: Mater. Electron. 23, 1108 (2012)

G.Y. Li, B.L. Chen, J.N. Tey, IEEE Trans. Electron. Packag. Manuf. 27, 77 (2004)

Z. Moser, P. Fima, K. Bukat, J. Sitek, J. Pstrus, W. Gasior, M. Koscielski, T. Gancarz, Solder. Surf. Mt. Tech. 23, 22 (2011)

K. Bukat, M. Koscielski, J. Sitek, M. Jakubowska, A. Mlozniak, Solder. Surf. Mt. Technol. 23, 150 (2011)

B.L. Chen, G.Y. Li, IEEE Trans. Compon. Packag. Technol. 28, 534 (2005)

Y.D. Han, S.M.L. Nai, H.Y. Jing, L.Y. Xu, C.M. Tan, J. Wei, J. Materater, J. Mater. Sci.: Mater. Electron. 22, 315 (2011)

X.L. Zhong, M. Gupta, Adv. Eng. Mater. 7, 1049 (2005)

L.C. Tsao, C.H. Huang, C.H. Chung, R.S. Chen, Mater. Sci. Eng., A 545, 194 (2012)

L.C. Tsao, M.W. Wu, S.Y. Chang, J. Mater. Sci.: Mater. Electron. 23, 681 (2012)

S.Y. Chang, C.C. Jain, T.H. Chuang, L.P. Feng, L.C. Tsao, Mater. Des. 32, 4720 (2011)

L.C. Tsao, S.Y. Chang, Mater. Des. 31, 990 (2010)

J. Shen, Y.C. Liu, Y.J. Han, Y.M. Tian, H.X. Gao, Mater. Sci. Eng., A 441, 135 (2006)

J. Shen, Y.C. Chan, J. Alloys Compd. 477, 552 (2009)

M. Amagai, Microelectron. Reliab. 48, 1 (2008)

D.C. Lin, G.X. Wang, T.S. Srivastna, M. Al-Hajri, M. Patraroli, Matter. Lett. 53, 333 (2002)

D.C. Lin, S. Liu, T.M. Guo, G.X. Wang, T.S. Srivastna, M. Patraroli, Mater. Sci. Eng., A 360, 285 (2003)

L. Zang, Z. Yuan, H. Xu, B. Xu, Appl. Surf. Sci. 257, 4877 (2011)

X.R. Zhang, Z.F. Yuan, H.X. Zhao, L.K. Zang, J.Q. Li, Chinese Sci. Bull. 55, 797 (2010)

L.C. Tsao, J. Alloys Compd. 509, 2326 (2011)

Acknowledgments

The financial support of this work from the Planned Science and Technology Project of Guangdong Province under the Project 2012B020313004 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, Y., Pan, Y.C. & Li, G.Y. Influence of TiO2 nanoparticles on thermal property, wettability and interfacial reaction in Sn–3.0Ag–0.5Cu–xTiO2 composite solder. J Mater Sci: Mater Electron 24, 1587–1594 (2013). https://doi.org/10.1007/s10854-012-0980-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-012-0980-6