Abstract

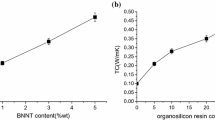

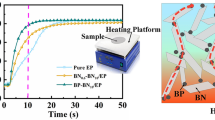

Boron nitride-filled epoxy laminate with excellent thermal conductivity was prepared. Its thermal conductivity was enhanced through sliane surface treatment prior to mixing the epoxy. The lamination enhanced thermal conductivity of the boron nitride filled epoxy by 20 % by reducing the voids in the structure. The heat conduction mechanism in laminated board, i.e. BN, glass fabric and epoxy, is not the same as a simpler BN-epoxy system, even though thermal conductivity of epoxy laminate is mainly affected by filler size and contents, as in the case of BN-epoxy composite. This study provides evidence of the importance of temperature and pressure after surface engineering of boron nitride for fabricating high thermal conductivity laminates, establishing the prerequisites for maximizing thermal conductivity of BN-epoxy laminate. The infrared thermogram showed that the BN-laminate can effectively lower the temperature of a surface mounted LED by 12.5 °C compared to the traditional FR4. According to the IESNA LM 80 lifetime testing method, this reduction in LED temperature is equivalent to increasing the LED’s lifetime by 21,000 h.

Similar content being viewed by others

References

M. Fishcher, R. Schmid, Polymere werkstoff, band I (Verlag, New York, 1986)

C.I. Nicholls, H.M.J. Rosenberg, Phys. C: Solid State Phys. 17, 1165 (1984)

K.W. Garret, H.M.J. Rosenberg, Phys. D: Appl. Phys. 7, 1247 (1974)

H.J. Ott, Plast. Rubber Process. Appl. 1, 9 (1981)

P. Procter, J. Solc, IEEE Trans. Comp. Hybrids Manu. Tech. 14, 708 (1991)

H. He, R. Fu, Y. Han, Y. Shen, X. Song, J. Mater. Sci. 42, 6749 (2007)

D.M. Bigg, Polym. Compos. 7, 125 (1986)

D.P.H. Hasselman, L.D.J. Johnson, Compos. Mater. 21, 508 (1987)

G.I. Batchelor, R.W.O. Brien, Proc. R. Soc. Lond. Ser. A 355, 313 (1977)

Z. Li, K. Okamoto, Y. Ohki, T. Tanaka, IEEE Trans. Dielectr. Electr. Insul. 17, 653 (2010)

A.A. Solomo, J. Fourcade, S.G. Lee, S.K. Kuchibhotla, S. Revankar, R. Latta, P.L. Holman, J.K. McCoy, in Proceedings of the 2004 international Meeting on LWR Fuel Performance, Orlando, 2004, p. 1028

M. Hussain, Y. Oku, A. Nakahira, K. Niihara, Mater. Lett. 26, 177 (1996)

P. Bujard, G. Kü hlein, S. Ino, T. Shiobara, IEEE Trans. Compon. Packag. Manuf. Technol. A 17, 527 (1994)

Y. Xu, D.D.L. Chung, C. Mroz, Compos. A 32, 1749 (2001)

W. Kim, J.W. Bae, I.D. Choi, Y.S. Kim, Polym. Eng. Sci. 39, 756 (1999)

W. Bae, W. Kim, S.W. Park, C.S. Ha, J.K.J. Lee, Appl. Polym. Sci. 83, 2617 (2002)

M.T. Huang, H.J. Ishida, Polym. Sci. Part B: Polym. Phys. 37, 2360 (1999)

R.S. Pease, Acta Crystallogr. 5, 236 (1952)

L. Li, D.D.L.J. Chung, Electron. Mater. 23, 557 (1994)

K.C. Yung, H.M. Liem, J. Appl. Polym. Sci. 106, 3587 (2007)

K.C. Yung, J. Wang, T.M. Yue, J. Compos. Mater. 42, 2615 (2008)

K.C. Yung, B.L. Zhu, T.M. Yue, Z.S. Xie, J.J. Wu, Polym. Sci. Part B: Polym. Phys. 45, 1662–1674 (2006)

R.L. McCullough, Compos. Sci. Technol. 22, 3 (1986)

L. Ekstrand, H. Kristiansen, J. Liu, 28th International Spring Seminar on Electronics Technology: Meeting the Challenges of Electronics Technology Progress, 2005, 35

G.A. Slack, R.A. Tanzilli, R.O. Pohl, J.W. Vandersande, J. Phys. Chem. Solids 48, 641 (1987)

K. Saito, S. Miyashita, J. Phys. Soc. Jpn. 71, 2485 (2002)

Z. Wang, T. Iizuka, M. Kozako, Y. Ohki, T. Tanaka, IEEE Trans. Dielectr. Electr. Insul. 2011, 18 (1963)

Acknowledgments

This work was funded by the Hong Kong Innovation Technology Fund (ITF) under project number ITS/257/09FP.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yung, K.C., Liem, H. & Choy, H.S. Prerequisite for maximizing thermal conductivity of epoxy laminate using filler. J Mater Sci: Mater Electron 24, 1095–1104 (2013). https://doi.org/10.1007/s10854-012-0886-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-012-0886-3