Abstract

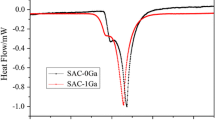

In this work, Sn3.0Ag0.7Cu (SAC) composite solders were produced by mechanically intermixing 0.5 wt% Al2O3 nanoparticles into Sn3.0Ag0.7Cu solder. The formation and growth kinetics of the intermetallic compounds (IMC) formed during the liquid–solid reactions between SAC-0.5Al2O3 composite solder and Cu substrates at various temperatures ranging from 250 to 325 °C were investigated, and the results were compared to the SAC/Cu system. Scanning electron microscopy (SEM) was used to quantify the interfacial microstructure for each processing condition. The thickness of interfacial intermetallic layers was quantitatively evaluated from SEM micrographs using imaging software. Experimental results showed that IMC could be dramatically affected by a small amount of intermixing 0.5 wt% Al2O3 nanoparticles into Sn3.0Ag0.7Cu solder. A continuous elongated scallop-shaped overall IMC layer was found at SAC/Cu interfaces. However, after the addition of Al2O3 nanoparticles, a discontinuous rounded scallop-shaped overall IMC layer appeared at SAC-0.5Al2O3/Cu interfaces. Kinetics analyses showed that growth of the overall IMC layer in SAC/Cu and SAC-0.5Al2O3/Cu soldering was diffusion controlled. The activation energies calculated for the overall IMC layer were 44.2 kJ/mol of SAC/Cu and 59.3 kJ/mol for SAC-0.5Al2O3/Cu soldering, respectively. This indicates that the presence of a small amount of Al2O3 nanoparticles is effective in suppressing the growth of the overall IMC layer.

Similar content being viewed by others

References

M. Abtew, G. Selvaduray, Mater. Sci. Eng. A27, 95–141 (2000)

I. Anderson, J. Mater. Sci: Mater. Electron. 18, 55–76 (2007)

J. Glazer, J. Electron. Mater. 23, 693–700 (1994)

J. Glazer, Inter. Mater. Rev. 40, 65–93 (1995)

J. Shen, Y.C. Chan, Microelectron. Rel. 49, 223–234 (2009)

H. Mavoori, S. Jin, J. Electron. Mater. 27, 1205–1210 (1998)

L.C. Tsao, S.Y. Chuang, Mater. Des. 31, 990–993 (2010)

L.C. Tsao, S.Y. Chang, C.I. Lee, W.H. Sun, C.H. Huang, Mater. Des. 31, 4831–4835 (2010)

J.H. Lee, J.H. Park, Y.S. Kim, D.H. Shin, J. Mater. Res. 16, 1227–1230 (2001)

R.A. Gaqliano, M.E. Fine, J. Electron. Mater. 32, 1441–1447 (2003)

A. Zribi, A. Clark, L. Zavalij, P. Borgesen, E.J. Cotts, J. Elect. Mater. 30, 1157–1164 (2001)

K.S. Kim, S.H. Huh, K. Suganuma, Microelectr. Rel. 43, 259–267 (2003)

W. Yang, E.Felton. Lawrence, Robert.W. Messler Jr, J. Electron. Mater. 24, 1465–1472 (1995)

T.L. Su, L.C. Tsao, S.Y. Chang, T.H. Chuang, JMEPEG 11, 365–368 (2002)

R.W. Wu, L.C. Tsao, S.Y. Chang, C.C. Jain, R.S. Chen, J.Mater Sci. Mater. Electron. 22, 1181–1187 (2011)

R.J.K. Wassink, (Electrochemical Publications Ltd., Ayr, Scotland, 1989), p. 149

T.H. Chuang, M.W. Wu, S.Y. Chang, S.F. Ping, L.C. Tsao, J.Mater. Sci. Mater. Electron. 22, 1021–1027 (2011)

J. Shen, Y.C. Liu, Y.J. Han, Y.M. Tian, H.X. Gao, J. Electron. Mater. 35, 1672–1679 (2006)

M. Harada, R. Satoh, IEEE Trans. Comp. Hybrids. Manuf. Tech. 13, 736–742 (1990)

R.A. Gagliano, M.E. Fine, JOM 53, 33–38 (2001)

A. Sharif, Y.C. Chan, J. Alloys.Compd. 390, 67–93 (2005)

K.H. Prakash, T. Sritharan, Acta Mater. 49, 2481–2489 (2001)

D.Q. Yu, L. Wang, J. Alloys.Compd. 458, 542–547 (2008)

H.L. John, L.H. Pang, X.Q. Xu et al., J Electron Mater 33, 1219–1226 (2004)

H. Schoeller, S. Bansal, A. Knobloch, D. Shaddock, J. Cho, J Electron Mater 38, 802–809 (2009)

G. Zeng, S. Xue, L. Zhang, L. Gao, W. Dai, J. Luo, J Mater Sci. Mater Electron. 21, 421–440 (2010)

J.C. Leong, L.C. Tsao, C.J. Fang, C.C. Ping, J Mater Sci. Mater Electron. doi:10.1007/s10854-011-0327-8

K. Suganuma, K.S. Kim, S.H. Huh, in International symposium on microelectronics (IMAPS, Washington, DC, 2001), pp. 529–534

L.C. Tsao, J. Alloys. Compd. 509, 2326–2333 (2011)

L.C. Tsao, C.P. Chu, S.F. Peng, Microelectron. Eng. (2011). doi:10.1016/j.mee.2011.04.034

L.C. Tsao, J. Alloys Compd. 509, 8441–8448 (2011)

X.Y. Liu, M.L. Huang, C.M.L. Wu, L. Wang, J. Mater. Sci.: Mater. Electron. 21, 1046–1054 (2010)

S.M.L. Nai, M. Gupta, J. Wei, in 2nd IEEE international nanoelectronics conference, (2008). pp. 15–19

S.M.L. Nai, J. Wei, M. Gupta, J. Alloys. Compd. 473, 100–106 (2009)

A.K. Gain, T. Fouzder, Y.C. Chan, K. Winco, C. Yung, J. Alloys Compd. 509, 3319–3325 (2011)

S.Y. Chang, C.C. Jain, T.H. Chuang, L.P. Feng, L.C. Tsao, Mater. Des. (2011). doi:10.1016/j.matdes.2011.06.044

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, S.Y., Tsao, L.C., Wu, M.W. et al. The morphology and kinetic evolution of intermetallic compounds at Sn–Ag–Cu solder/Cu and Sn–Ag–Cu-0.5Al2O3 composite solder/Cu interface during soldering reaction. J Mater Sci: Mater Electron 23, 100–107 (2012). https://doi.org/10.1007/s10854-011-0476-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-011-0476-9