Abstract

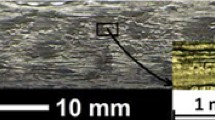

In this study, copper particles with different sizes 20–30 nm, 3 and 10 μm were incorporated into Sn-3.5Ag solder paste to form Sn–Ag–Cu composite solder. The Cu particles were added at 0.7 and 3% by paste mixing for 30 min. The composite solder samples were prepared on copper substrate at 240°C for 60 s. Differential scanning calorimetry was conducted to measure the melting point of the composite solder. The wetting angle and microstructure of the composite solder were studied using optical microscope and scanning electron microscope. Micro hardness was measured using a 10 gf load. It was reported that the lowest melting point was obtained at 216.3°C when Cu nanoparticles was added at 3% to Sn-3.5Ag. The microstructure of Sn-3.5Ag solder structure was dendritic in nature. With the addition of Cu nanoparticles, the microstructures were modified with more refined Sn structures. The existence of sunflower morphology of un-melted copper was observed when Cu microparticles were added.

Similar content being viewed by others

References

K. Zeng, K.N. Tu, Mater. Sci. Eng. 38(2), 55–105 (2002)

J. Pan, B.J. Toleno, T.C. Chou, W.J. Dee, Sold. Surf. Mount Technol. 18(4), 48–56 (2006)

H. Hao, Y. Shi, Z. Xia, Y. Lei, F. Guo, J. Electron. Mater. 37(1), 1–8 (2008)

K.W. Moon, W.J. Boettinger, U.R. Kattner, F.S. Biancaniello, C.A. Handwerker, J. Electron. Mater. 29(10), 1122–1136 (2000)

F. Guo, J Mater. Sci. Mater. Electron. 18(1–3), 129–145 (2007)

S.Y. Hwang, J.W. Lee, Z.H. Lee, J. Electron. Mater. 31(11), 1304–1308 (2002)

D.C. Lin, T.S. Srivatsan, G.X. Wang, R. Kovacevic, Powder Technol. 166(1), 38–46 (2006)

W.K. Choi, J.H. Kim, S.W. Jeong, H.M. Lee, J. Mater. Res. Soci. 17(1), 43–51 (2002)

J.L. Marshall, J. Calderon, J. Sees, G. Lucey, J.S. Hwang, IEEE Trans. Compon. Hybrids Manuf. Technol. 14(4), 698–702 (1991)

J.L. Marshall, J. Calderon, Solid Surf. Mount Technol. 26, 22–28 (1997)

H.L. Lai, D.H. Guh, J. Electron. Mater. 32(4), 215–220 (2003)

M. Amagai, Microelectron. Reliab. 48, 1–16 (2008)

D.C. Lin, G.X. Wang, T.S. Srivatsan, M. Al-Hajria, M. Petraroli, Mater. Lett. 57, 3193–3198 (2003)

V. Sivasubramaniam, N.S. Bosco, J.J. Rusch, J. Cugnoni, J. Botsis, J. Electron. Mater. 37(10), 1598–1604 (2008)

P. Yao, P. Liu, J. Liu, J. Alloys Compd 462(1–2), 73–79 (2008)

Y.W. Wang, C.C. Chang, C.R. Kao, J. Alloys Compd. 478(1–2), L1–L4 (2009)

P. Jr. Scarber, G.M. Janowski, Modeling of Composites; Proceeding and Properties, Anaheim, CA, Mineral, Metal, Materials Society/AIME, 57–75 (1996)

J.G. Lee, F. Guo, K.N. Subramanian, J.P. Lucas, Solder. Surf. Mount Technol. 14(2), 11–17 (2002)

F. Gao, S. Mukherjee, Q. Cui, Z. Gu, J. Phys. Chem. 113, 9546–9552 (2009)

B. Reddy, P. Bhattachary, B. Singh, Mater. Sci. Eng. 44(9), 2257–2263 (2008)

J. Shen, Y.C. Chan, Microelectron. Reliab. 49(3), 223–234 (2009)

F. Ochoa, J.J. Williams, N. Chawla, J. Miner. Metals Mater. Soci. 55(6), 56–60 (2003)

P. Liu, P. Yao, J. Liu, J. Electron. Mater. 37(6), 874–879 (2008)

D.C. Lin, T.S. Srivatsan, G.X. Wang, R. Kovacevic, J. Mater. Eng. Perform. 16(5), 647–654 (2007)

S. Bader, W. Gust, H. Hieber, Acta Metallurgica Et Materialia 43(1), 329–337 (1995)

L. Xu, J.H.L. Pang, K.H. Prakash, T.H. Low, IEEE Trans. Compon. Packag. Tech. 28(3), 408–414 (2005)

K.H. Prakash, T. Sritharan, J. Electron. Mater. 32(9), 939–947 (2003)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nadia, A., Haseeb, A.S.M.A. Effects of addition of copper particles of different size to Sn-3.5Ag solder. J Mater Sci: Mater Electron 23, 86–93 (2012). https://doi.org/10.1007/s10854-011-0441-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-011-0441-7