Abstract

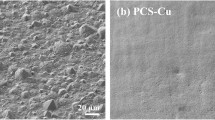

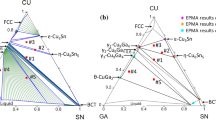

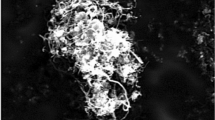

Kirkendall voids (KVs) have disastrous effects on the properties of the solder joints in the integrated circuits, which are formed after the occurrence of the Cu3Sn intermetallic compound (IMC) layer at the Sn-based solder/Cu interface. In this paper, 0.1 and 0.3 wt% Ge additions were separately added into the Sn-3.5 wt%Ag eutectic solder, to investigate the effects of Ge on the interfacial reaction under thermal aging at 150 °C. It is found that the Cu6Sn5 layer was still the original product, regardless of the concentration of Ge. Moreover, Ge was identified to dissolve into the IMC layer. As the aging time was prolonged to 10 days, the concentration of Ge increased to about 3.0 at%, but the Cu3Sn IMC layer was not obvious. The single Cu6Sn5 IMC layer became flat little by little. Meantime, the thickness of the IMC layer increased slowly. And more significant finding is that the KVs were also not obvious at the interface.

Similar content being viewed by others

References

M. Abtew, G. Selvaduray, Mater. Sci. Eng. 27, 95 (2000)

C.M.T. Law, C.M.L. Wu, D.Q. Yu, M. Li, D.Z. Chi, IEEE Trans. Adv. Pack. 28, 252 (2005)

J.W. Yoon, S.B. Jung, J. Alloys Compd. 407, 141 (2006)

K.J. zeng, R. Stierman, T.C. Chiu, J. Appl. Phys. 97, 024508 (2005)

Y.W. Wang, Y.W. Lin, C.R. Kao, Microelectron. Reliab. 49, 248 (2009)

X.Q. Lin, L. Luo, J. Electron. Mater. 37, 307–313 (2008)

L.H. Xu, J.H.L. Pang, F.X. Che, J. Electron. Mater. 37, 880–886 (2008)

J.Y. Kim, J. Yu, Appl. Phys. Lett. 92, 092109 (2008)

F. Gao, H. Nishikawa, T. Takemoto, J. Electron. Mater. 37, 45–50 (2008)

W.J. Plumbridge, J. Mater. Sci. 31, 2501 (1996)

F. Ochoa, J.J. Williams, N. Chawla, J. Electron. Mater. 32, 1414 (2003)

S. Wan Cho, K. Han, Y. Yeonjin, S.J. Kang, K.-H. Yoo, K. Jeong, C.-N. Whang, Adv. Eng. Mater. 8, 111–114 (2006)

Y.S. Lai, J.M. Song, H.C. Chang, Y.T. Chiu., J. Electron. Mater. 37, 201 (2008)

I.E. Anderson, J.L. Harringa, J. Electron. Mater. 35, 94 (2006)

M. Amagai, Microelectron. Reliab. 48, 1 (2008)

K.L. Lin, P.C. Shih, J. Alloys Compd. 452, 291 (2008)

G. Meng, T. Yang, L. Chen, S. Wang, C. Li, Trans. China Weld. Inst. 29, 51–53 (2008)

C. Yu, H. Lu, S.M. Li, J. Alloys Compd. 460, 594 (2008)

F. Gao, T. Takemoto, H. Nishikawa, Mater. Sci. Eng. A 420, 39–46 (2006)

F. Wang, X. Ma, Y. Qian, Scr. Mater. 53, 699–702 (2005)

C. Yu, J. Liu, H. Lu, P. Li, J. Chen, Intermetallics 15, 1471–1478 (2007)

B. Chao, S.H. Chae, X.F. Zhang, J. Appl. Phys. 100, 084909 (2006)

C. Yu, Y. Yang, H. Lu, J.M. Chen, J. Electron. Mater. 39, 1309 (2010)

Acknowledgments

This work was supported by the National Natural Science Foundation of China under Project No. 50975176, and No. 51035004.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, C., Yang, Y., Li, P. et al. Suppression of Cu3Sn and Kirkendall voids at Cu/Sn-3.5Ag solder joints by adding a small amount of Ge. J Mater Sci: Mater Electron 23, 56–60 (2012). https://doi.org/10.1007/s10854-011-0412-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-011-0412-z