Abstract

In this paper, we were able to crystallize InGaZnO4 (IGZO) by excimer laser on SiO2 substrate. It was observed that uniform [0001] textured polycrystalline IGZO film has been obtained without any grain boundaries and oxygen vacancies on SiO2 substrate. This process is very promising in fabricating high quality IGZO thin film transistors (TFT) at low temperature without seed substrate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

High performance poly-Si TFT is gaining more interest in integrating controllers, signal processors and memories with display. Oxide semiconductor materials with a wide band gap have attracted many interests as a channel material for TFT fabrication due to its higher mobility than that of a-Si. Especially Zinc Oxide (ZnO) has been proven to be a promising transparent semiconductor material due to the good uniformity, high optical transparency, and device stability. Recently Hosono et al. [1] reported that highly uniform [0001] InGaZnO4 (IGZO) film can be grown directly on YSZ glass substrate. It was also reported that the ZnO on glass substrate can easily be textured to [0001] [2, 3]. However, the temperature of solid phase crystallization is up to 950 °C which is not suitable to fabricate crystalline IGZO TFTs on glass or flexible substrate. Excimer laser annealing (ELA), which can raise the temperature of IGZO films in a very short time (20 ns), is effective to crystallize IGZO films without damage the substrate. Since the crystallization time is very short during excimer laser annealing, few oxygen vacancies are generated which is very promising for fabricating high performance TFTs. Furthermore, solid phase crystallization required YSZ glass as seed layer which limited its further application on amorphous glass substrate. In this paper, we propose to crystallize the IGZO film by excimer laser annealing directly on SiO2 at room temperature.

2 Experiment

Figure 1 shows the structure of cross section: 1,000 nm SiO2 has been thermally grown on SiO2 to isolate the film from Si substrate and prevent heat diffusion into substrate during excimer laser crystallization. Then 50 nm InGaZnO4 film has been sputterred at a substrate temperature of 25°C. Then the InGaZnO4 film was deposited in a gas mixture of argon and oxygen. The ratio of O2 to Ar was 1:19. The RF power was 70 W. The total gas pressure during the deposition was 0.55 Pa. The samples was irradiated by the single shot XeCl excimer laser (λ = 308 nm). The distance between the target and the substrate was 75 cm. The energy densities of excimer laser irradiation were 600, 800 and 1,000 mJ/cm2. The pulse width of excimer laser was 20 ns. The width and the length of the laser shot were 450 and 350 nm respectively. The irradiation was carried out at a substrate temperature of 25 °C in vacuum chamber.

3 Results and discussion

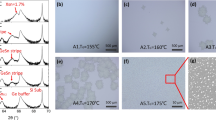

Figure 2 shows X-Ray diffraction (XRD) analysis of IGZO film which has been shot by excimer laser. For the 50 nm thick film, no diffraction peaks of the IGZO crystals were observed at the laser energy density of 600 mJ/cm2, which suggests that the IGZO films remained amorphous at the laser energy density of 600 mJ/cm2. In contrast, crystal IGZO diffraction peaks appeared when the laser energy was above 800 mJ/cm2, which indicated that the IGZO film has been crystallized. So the threshold energy density of laser crystallization for the 50 nm IGZO film was 800 mJ/cm2. At laser energy of 1,000 mJ/cm2, we see IGZO periodic diffraction peaks of (003) (006) (009) (0012) (0015), and (0018) which suggests that IGZO films with (001) surface orientation has been achieved. Also a Zn2SiO4 phase has been found which indicates that Zn silicate has been formed at interface between IGZO and SiO2 film.

Figure 3 a and b shows Transmission Electron Microscopy (TEM) image of IGZO film by excimer laser irradiation at energy densities of 600 and 1,000 mJ/cm2 respectively. TEM image shows that at a low energy density of 600 mJ/cm2 (Fig. 3a), the orientation of the film is random with grain defects. However, at the laser energy of 1,000 mJ/cm2 (Fig. 3b), the film has (001) orientation preference and no defects, such as grain boundaries and dislocations, have been observed by TEM. The film has been uniformly crystallized with (001) orientation preference which was correspondent with XRD result. The advantage of the excimer laser crystallization over the traditional solid phase crystallization is that it can heat up the IGZO film locally to crystallization temperature in very shot time (20 ns) without damage the substrate. Moreover, since the crystallization time is so short, oxygen diffusion is suppressed which is an advantage over traditional thermal annealing process.

4 Conclusions

We have investigated the excimer laser annealing of IGZO films. IGZO film can be crystallized by excimer laser with (001) orientation preference without seed layer. The IGZO film after laser crystallization has no grain boundaries and dislocations by TEM observation which is very promising to fabricate high performance thin film transistors on glass substrate.

References

K. Nomura, H. Ohta, K. Ueda, T. Kamiya, M. Hirano, H. Hosono, Science 300, 1269–1272 (2003)

N. Fujimura, T. Nishihara, S. Goto, J. Xu, T. Ito, J. Cryst Growth. 130, 269–279 (1993)

M.K. Puchert, P.Y. Timbrell, R.N. Lamb, J. Vac. Sci. Technol. A 14(4), 2220 (1996)

Acknowledgments

This work is supported by the Dutch Science and Technology Foundation (STW) (No.DMF.6617).

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Chen, T., Wu, MY., Ishihara, R. et al. Excimer laser crystallization of InGaZnO4 on SiO2 substrate. J Mater Sci: Mater Electron 22, 1694–1696 (2011). https://doi.org/10.1007/s10854-011-0347-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-011-0347-4