Abstract

Ion beam sputtering (IBS) can induce nanoripple patterns in a short time on variety of materials for wide range of applications. In this work, we describe the nanoripple as well as terrace pattern formation by IBS on soda-lime glass surfaces and the mechanisms leading to such pattern formations. The role of ion energy, ion fluence, and ion incidence angle on the morphology of the structural features is systematically explored. For a range of ion beam parameter values with energy varying from 600 to 1500 eV and fluence in the range 9.7 × 1017 to 2.0 × 1019 ions/cm2 at fixed incidence angle of 45°, transition of ripples to terraces has been observed. The experimental results are explained on the basis of recently modified KS equation which clearly explains the simultaneous role of nonlinear cubic term in the terrace formation. It is also demonstrated how ion beam can be used to tailor the wettability of glass surface and makes it hydrophobic in nature. Due to pattern formation, anisotropic hydrophobicity is observed showing an increasing trend owing to the magnification of the amplitude of nanopatterns developed on the surface.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Soda-lime glass is the most common type of glass having widespread usage in glass containers, windowpanes, top surface of solar panel, bake ware and many more as it is inexpensive, chemically stable, and hard enough to be used for variety of purposes. Due to its composition, it exhibits lower glass transition temperature as well as better chemical durability. Surface modifications of glass surface have been extensively studied using ion implantation as well as coating methods to improve their properties be it like chemical or optical properties, hydrophobic or hydrophilic properties, which are important for control of wetting to liquid as well as thin film adhesion applications [1, 2]. Hydrophobicity is crucial for glass surfaces to prevent dirt, algae, and acids. For decades, efforts have focused on enhancing surface performance through coatings, but their durability remains a concern due to unpredictable changes in optical properties with temperature and humidity [3]. Significant work has been done on fabricating hydrophobic surfaces, mainly focusing on chemical patterns. However, chemical coatings are costly and not permanent. Additionally, femtosecond laser pulses have been used to create micron-scale patterns to modify surface properties [4,5,6]. Although this method makes the glass surface super-hydrophobic, it compromises transparency and has limitations for large areas. Sputter deposition techniques have been developed to overcome these issues, improving durability, film quality, and other optical properties [7,8,9]. Their main concern was to study the changes of crystal structure as well as their composition to modify the properties of the coatings. But even with coating improvements, the contact angle achieved was only up to 80° [3]. Ion beam has also been used as a tool to make surfaces hydrophobic in nature [10]. For instance, wetting properties of Si surfaces have been engineered using high energy, i.e., 60 keV Ar ions for self-cleaning process as it is desirable in solar cell applications which can increase in their efficiency, also to make hydrophobic lab-on-chip devices [11]. Investigations on glass surface from this aspect are missing. So, we propose a much promising and durable method to make the glass surface hydrophobic using low energy in nature by formation of nanopatterns using low-energy ion beam sputtering (IBS) process.

Surface nanopatterning using IBS has attracted a lot of attention since last few decades from fundamental as well as experimental and application point of view [12,13,14,15]. It was first discovered by Navez et al. in 1962 that when a surface is exposed to ion beam, nanoscale ripple patterns develop on the surface [16]. Bombarding a solid surface using ion beam can lead to a variety of self-organized nanoscale patterns like surface ripples, cones, pits, mounds, etc. Since then, it has attracted interest in a variety of fields because of its potential to become a single-step method of producing nanopatterns on large area templates with length scales varying from few nm up to µm as required for different applications ranging from optical, plasmonics, magnetic storage devices, bio-sensing devices, wettability, solar cells, and to many more [3, 8, 17,18,19]. Extensive work was carried out regarding pattern formation on semiconductors, especially, Si and Ge surfaces, as they both are a simple, mono elemental system, as well as it readily gets amorphized during ion irradiation [20,21,22,23,24,25,26,27,28,29,30,31]. Along with ripple morphology, triangular features are also observed to superimpose them in case of monoelemental surfaces, as reported in some of our previous works as well [15, 22, 32,33,34,35,36]. Studies have also been carried out on other materials like SiO2 [37], HOPG surfaces [38], diamond [39], GaAs [40], etc., to study the evolution of ripples as a function of different ion beam parameters. Since patterned SiO2 surfaces are found to be effective for tailoring many physical properties, so investigations have been performed on this material by various groups [41,42,43,44]. Silica samples were explored via ion irradiation to study the evolution of nanoscale patterns, because of its technological relevance mainly as a substrate for high-temperature growth processes. For instance, Keller et al. reported the evolution of ripple patterns using sub-keV ion bombardment on three different types of silica (thermally grown SiO2 films, fused silica, commercially available quartz wafers) at selective ion energy and angles of incidence [45]. They also observed terrace formation with different sets of parameters, such as for fused silica using 800 eV Ar ions at an ion incidence angle of 70°, and for Si (100) using 60 keV Ar ions at an incidence angle of 60°. Systematic investigations were performed by Kumar et al. on thermally grown SiO2 in the (200 – 1000 eV) energy range, fluence window (1.0 × 1016–1.0 × 1018 ions/cm2) and angular window (40°–70°) using Ar-ions. Additionally, they carried out numerical estimations using SDTrimSP simulations, based upon theoretical models of ion-induced surface evolution to understand the physical processes contributing to the pattern formation [46]. Even investigations have been performed on silica glass with high-energy (– 1MeV) Au ions at various angles of incidence. Srivastava et al. observed ripple formation in y-direction which is opposite to what is observed in low-energy regime. Moreover, there is shape transformation of ripples from sinusoidal to saw tooth when the fluence dose was increased which they explained due to pattern coarsening. Overall, they explained the pattern formation in high-energy regime on the basis of ion-induced surface stress, surface current of recoiled atoms and mass redistribution due to crater formation [47].

Although studies have been performed on SiO2 mainly for pattern evolution and its application, the systematic investigations on pattern formation and their evolution on soda-lime glass which consists of other elements as well is still lacking. Nanopatterned glass surfaces can be utilized for various applications, such as in optoelectronics, plasmonics, electrical conductivity, bio-sensing as well as for wettability. For example, Giordano et al. reported the formation of facets on glass surface using defocused 800 eV Ar ion beam in the angle window 0°–55° but by heating up the glass substrates near its transition temperature which is about 550 – 600 °C and at ion fluence of 1.4 × 1019 ions/cm2 [48]. They also observed ripple patterns at 800 eV, and some studies have reported patterns at even lower energies but with high fluence values [49, 50]. The motive of this work was to utilize facets produced by ion beam to improve anisotropic electrical transport properties of nanopatterned film on glass substrates which have the potential in nanoelectronics, optoelectronics as well as bio-sensing.

We studied the development of nanoscale terraces during broad ion beam sputtering (IBS) of soda-lime glass. Consequently, observed patterning process of soda-lime glass surface in the low-energy regime turns out to be analogous to those of Si, SiO2, silica surfaces, as the main elements of soda-lime glass consists of Si and O with other elements in lower percentage (O–0.6%, Si–0.25%, Na–0.1%, Ca–0.03%, Mg–0.01%, Al–0.01%). This study shows the generality of pattern formation on surfaces under low-energy (500 – 1500 eV) ion beams, advancing our understanding of ion-induced patterns on solid surfaces. We systematically studied the transition from ripples to terrace features on soda-lime glass with different ion beam parameters, guided by a theoretical framework. While nanopatterns on glass have been used for various applications, making glass hydrophobic with low-energy ion beams has not been reported. This work focuses on nanopattern formation on soda-lime glass and its wettability tunability with different ion beam parameters, explaining the transition from ripples to terrace features.

The very first continuum model by Bradley and Harper (BH) based on Sigmund’s assumption of energy distribution is ellipsoidal in shape in a target when ion hits the surface [51, 52]. BH described pattern formation on solid surfaces as a competition between erosive processes and smoothing due to surface diffusion. However, limitations in their theory led to further modifications by various groups [53, 54]. Eventually, the theories till now have focused mainly on monoelemental surfaces but with advancements on binary materials in the last decade. Recently, a theoretical approach was made by Tejas et al. [55], based on Ou’s [56] assumptions to explain the ripple morphology of a miscut (001) crystalline GaAs surface, which is a binary material. This model does not apply here due to low ion energy and the amorphous nature of soda-lime glass, where sputtering is significant. The anisotropic Kuramoto-Sivashinsky (AKS) equation fails to explain terraced topography, addressing only early-stage pattern formation. Pearson et al. added cubic nonlinearity terms, showing this term influences dynamics and leads to terraced topography, coarsening over time and reversing ripple propagation velocity as amplitude grows [53, 57, 58] This theory, applicable to amorphous materials with substantial sputtering, is relevant to our case. Following this approach, we explained the morphological evolution on soda-lime glass bombarded with noble gas ions. Previous simulations on Si and Ge using the modified equation showed dispersion’s role in forming triangular features [15, 21, 22, 58]. This work demonstrates the nonlinear cubic term’s role in terrace formation on compound materials.

In the first step, efforts have been made to find the key parameters responsible for the formation of various topographies which are identified as ion incidence angle (i.e., varied between 35° and 55°), erosion time (i.e., total fluence up to 2.0 × 1019 ions/cm2 was applied), and ion beam energy (which was varied from 500 eV to 1500 eV), and finally, we tried to identify the physical mechanisms underlying the formation of these features and what is responsible for transition from ripples to terraces when either ion energy or ion fluence is varied.

Experimental details

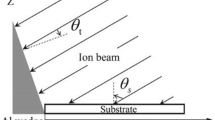

Soda-lime glasses with dimensions 20 × 20 × 1.3 mm3 with an initial root-mean-square (RMS) roughness of approximately 0.27 nm were first cleaned with acetone and isopropyl alcohol in ultrasonicator. These samples were irradiated using Kaufman-type ion source (Sinaris 40–i, Microsystems GmbH) with Ar+ ions in an ultra-high vacuum chamber with base pressure of ~10−8 mbar and operating pressure of ~10−4 mbar. The sample size can cover the whole sample holder such that no impurity fluxes come from the metallic sample holder during irradiation. Initially, irradiation was performed for a fixed oblique incidence angle of 45° with ion energy varying from 500 eV to 1500 eV. At 600 eV, ripples start forming which grows with ion energy and become terrace-type structures at higher energies (> 1000 eV). To observe dependency of these structures on ion incidence angle, further set of experiments were performed for fixed fluence of 6.9 × 1018 ions/cm2 at different ion incidence angles varying from 35° to 55° in the steps of 10° at 1000 eV ion energy, respectively. Final set of experiments were performed for different ion fluence values varying from 9.7 × 1017 to 2.0 × 1019 ions/cm2 for 1000 eV ion energy. The surface topography after irradiation was analyzed with NT-MDT make atomic force microscope (AFM) in the non-contact mode using silicon probes with a tip radius of 10 nm. The scanning was performed for 10 µm × 10 µm, 5 µm × 5 µm, 3 µm × 3 µm as well as 2 µm × 2 µm area for better statistical information and analysis. The wavelength of the structures was calculated from power spectral density (PSD) using WSxM software [59]. The wettability studies were carried out on Ar+- ion irradiated soda-lime glass surfaces along and across the ion beam direction as ripple patterns offer anisotropic friction to water droplet. The contact angle measurement of a water droplet on the irradiated surfaces was done by the sessile drop method by using a goniometer (OCA 15EC, Data physics), with contact angle measurement range of 0° – 180° and accuracy of ± 0.1°. This instrument used a computer-controlled syringe to dispose a 1.0 µL deionized Milli-Q water droplet on the surface under consideration. To check the uniformity, all the contact angles were measured on several randomly chosen locations. During measurements, the ambient temperature and relative humidity were maintained in the range 23 – 25 °C and 42 – 47%, respectively. The optical transmission coefficient from ultraviolet to infrared region of untreated and treated glass samples were also studied using VASE ellipsometer having high accuracy and precision with a wide spectral range from 200 up to 1100 nm.

Results and discussion

Figure 1 depicts the representative image of the ion irradiation process carried out on soda-lime glass sample and further contact angle measurements before and after irradiation with Ar+ ion beam. As shown on top side of Fig. 1, AFM image corresponds to a bare glass sample, i.e., prior to treatment, and hence, no surface features are present on it and on right-side is its water droplet image which spreads as soon as water droplet falls on the bare surface showing the hydrophilic nature of the sample as can be confirmed from the contact angle value which is around 38° for the bare surface. After ion beam irradiation for longer fluence (> 1.8 × 10 19 ions/cm2) values at an ion incidence angle of 45°, nanofeatures develop as seen from the bottom-side image of Fig. 1, leading to increase in contact angle value hence making the surface hydrophobic in nature. So just by ion irradiation process, one can make the soda-lime glass surface as hydrophobic.

Morphology evolution with ion energy

The evolution of surface morphology on soda-lime glass under Ar ion irradiation is represented in Figure 2(a) – (f) as a function of ion energy, \({E}_{ion}\) ion incidence angle (45°) and for a fixed ion dose of 6.9 × 1018 ions/cm2. The direction of projection of ion beam is indicated by black arrow on Fig. 2a, and the insets of the AFM images display the corresponding two-dimensional (2D) fast Fourier transform (FFT). No surface feature evolves for \({E}_{ion}\) < 500 eV. At ion energy of 600 eV, a weak ripple-like pattern appears with very low amplitude, having wave-vector parallel to the projected ion beam direction which is thought to be the threshold energy for the ripple pattern formation in the present experimental conditions (Fig. 2a). The periodic nature of the observed patterns becomes clear at 800 eV ion energy which is shown in Fig. 2b.

2×2 µm2 AFM images of ripple templates obtained on soda-lime glass using ion beam sputtering with ion energy varying from a 600 eV, b 800 eV, c 900 eV, d 1000 eV, e 1300 eV and f 1500 eV at a fixed ion fluence of 6.9 × 1018 ions/cm2, respectively. The insets of each AFM image display the corresponding 2D-FFTs. The black arrow indicates the direction of ion beam.

From the fast Fourier transform (FFT) shown in the inset of each AFM image, for 600 eV, there is a peak only at the center suggesting absence of periodicity for this energy value (Fig. 2a inset). The FFT of the 800 eV ripple topography shows that the bright spots have started forming on both sides of center spot along the x-direction (Fig. 2b inset). On further increase in ion energy to 900 eV, these bright spots appear situated symmetrically from the center spot implying that the wave vector of the pattern is parallel to the ion beam direction (Fig. 2c inset). Further increase of ion energy to 1000 eV, a different ripple-like morphology is seen to emerge (Fig. 2d). This is also apparent from the corresponding FFT image shown in the inset of Fig. 2d showing an elliptic spot with its major axis along the x-direction with no more bright spots present. Such topography seems to be the precursor of the transition of ripple pattern to terraces ridges. As the ion energy is increased beyond 1000 eV, the ripple structure disintegrates, and ordering becomes worse, rather terrace-like structure forms having higher amplitude and roughness (Fig. 2e – d). As evident from the corresponding FFTs, there is disappearance of the peaks as well the center spot squeezes suggesting that ripple ordering is lost (Fig. 2e – d inset). For better statistics, larger AFM scans were taken. Some of these images and their FFTs are included in the Supplementary Information (see Fig. A). The overall topographic evolution is quantitatively summarized in Fig. B in supplementary data as a function of ion energy, where the power spectral density (PSD) obtained from the AFM images of Fig. 2 are plotted.

Morphology evolution with ion incidence angle

Figure 3 shows the evolution of the ripple topography with ion incidence angle and their corresponding line profiles extracted from AFM images are shown in Fig. 4a. The glass samples are bombarded with 1000 eV Ar+ ions at different ion incidence angles at a fixed fluence of 6.9 × 1018 ions/cm2. For incidence angles lower than 30°, a nearly flat surface like the untreated surface was observed. However, at incidence angle 30°, irregular morphology with uneven elevations and depressions roughness around 38 nm develops having protrusions along the ion beam direction (Fig. 3a), with amplitude above 150 nm as can be observed from the corresponding line profile (Fig. 3a blue-curve). At ion incidence angle 35°, wavy-like structures or, say, broken irregular ripples form with reduced roughness around 28 nm (Fig. 5b), with decrease in amplitude (Fig. 3a) red-curve). Even there are not any bright spots present in the FFT shown in inset of Fig. 3a clearly depicting no regular periodic structures form for this angle of incidence. The ordering enhancement takes place for higher incidence angle, i.e., at 45°, a much like ripple topography develops with a bit regular periodicity in comparison with other angles of incidence (Fig. 3c).

2×2 µm2 AFM images of ripple templates obtained on soda-lime glass using 1000 eV ion energy with ion incidence angle varying from a 30°, b 35°, c 45° and d 55° at a fixed ion fluence of 6.9 × 1018 ions/cm2, respectively. The insets of each AFM image correspond to corresponding 2D – FFTs. The black arrow indicates the direction of ion beam. The bottom row represents the line profile of each corresponding image.

Even the line profile confirms the regularity of pattern formed at this incidence angle (Fig. 4a blue-curve). A modulation of the center spot along the x-direction also tends to appear in the corresponding FFT of this image but with no bright spots present suggesting the pattern is not highly ordered but they are periodic in nature. As the incidence angle is increased to 50°, the primitive shallow ripples along with extended structures along ion beam direction with much reduced roughness value develop on the surface (not shown). The same can be confirmed from the FFT as no clear spot forms for this structure. Further increase of incidence angle to 55°, a smooth morphology emerges with roughness somewhat reduced from that of lower incidence angles (Fig. 4d). The surface develops arrays of ripple-like features but with amplitude around 1–2 nm across the ion beam direction (Fig. 4a pink-curve)). As also apparent from the corresponding FFT image showing very light spot at the center. At larger angles, i.e., for θ > 55°, there is, however, a smooth surface almost like flat stable surface. So, under the angle of incidence variation from 30° to 55°, from a rough surface topography to an almost flat surface topography is achieved.

For quantitative analysis, PSD have been extracted from the AFM images as plotted in Fig. 4b. As mentioned before, that the position of the first peak in the PSD determines the characteristic frequency of the patterns, i.e., the wavelength of the structures, whereas the width of the peak gives information about the homogeneity of periodicity. The PSD spectra for 55° (pink-curve) show broad spectra with no peak as the surface is smooth. As the angle is reduced to 45° (blue-curve), there appears a peak corresponding to the periodic nature of the patterns, but the peak is broader as the patterns are not highly periodic. Further reducing the incidence angle to 35° (red-curve), the peak disappears again, and the spectra become broader but with a shift in upwards y-direction relating to increased roughness for lower incidence angles. Increasing the ion incidence angle from 35° to 55°, the PSD spectra shift downwards signify the smoothness of the surface with increased ion incidence angle. To determine quantitively whether the patterns observed develop terraces or not, it is better to calculate the slope distribution (determined from the AFM images).

So, in order to better understand the physical origin of this surface instability, we analyzed the evolution of the nanoscale slope distribution as a function of the ion beam parameters, i.e., ion incidence angle, and ion fluence. From the slope distribution, it can be inferred whether nonlinear effects are dominating or not during morphological evolution. If the slope distribution is symmetric, that signifies the ripple patterns are symmetric in nature and hence in linear regime, whereas if there is splitting of peaks, i.e., there are more peaks appearance at the positive and negative side with respect to the center of the distribution, the patterns are asymmetric in nature; basically it is an indication of formation of terraces, which means the nonlinear effects are dominating.

Firstly, to investigate further the morphological evolution, slope distribution is calculated with variation in ion incidence angle. Figure 5 shows the plot of the terrace slope angles α (°) for the patterns formed in the 30° – 55° ion incidence angle window using 1000 eV Ar ions.

At lowest ion incidence angle (Fig. 5a), i.e., 30°, the slope distribution is non-symmetrical as well as no well-defined peak, as can be observed from AFM topography as well, that there are no periodic patterns for this angle of incidence, which is also clearly depicted in the corresponding line profile. However, as the angle of incidence is increased to 35°, there is appearance of a peak signifying terrace formation in a preferential direction which corresponds to terraces formation (Fig. 5b). Further at ion incidence angle of 45°, the presence of peak is still there signifying ripple terraces which are not directly facing the ion beam (Fig. 5c). At 55°, an almost flat topography is achieved and hence a sharp isotropic peak in the centre confirming no more terraces is formed if angle of incidence is increased further (Fig. 5d). This shows that morphology has strong dependence on ion incidence angle with terrace evolution around 35° angle of incidence.

Morphology evolution with ion fluence

Till now we have shown, the experimental window of ripple formation and their transition to terraces with increase in ion energy. To investigate further how the ripple morphology evolves with ion dose, we examined the pattern evolution at different ion fluences.

In Fig. 6, we have shown the AFM morphology obtained at different ion fluences varying from 9.7 × 1017 ions/cm2 to 2.0 × 1019 ions/cm2 sputtered at 1000 eV and at a fixed ion incidence angle of 45°. At a very low fluence value, i.e., for 9.7 × 1017 ions/cm2 (Fig. 6a), the surface morphology shows the evolution of patterns with a roughness value around 1.6 nm. The surface does not exhibit any regularity as can also be evidenced from the corresponding FFT shown in the inset of Fig. 6a; showing ellipsoidal spot elongated along the direction of ion beam, signifying absence of periodicity has developed. As the ion fluence value is increased to 6.9 × 1018 ions/cm2, parallel-mode ripple-like patterns form with roughness increased to ten times to that of lower fluence. The same can be confirmed from the FFT where two spots with less intensity appear symmetrically w.r.t central bright spot signifying a periodicity has developed (Fig. 6b). These features transform to terrace-type structures with increased amplitude as well as roughness when ion fluence is further increased to 1.25 × 1019 ions/cm2 and hence the periodicity is also lost as no bright spots remain in the FFT of Fig. 6c. For fluence value 2.0 × 1019 ions/cm2, the features amplitude as well as lateral elongation increases and there is transformation to terraced ridges like features (Fig. 6d). The FFT also shows no peaks for this morphology developed on the surface. It is observed that there is transformation of ripples to terraced ridges features when ion dose is increased keeping other parameters constant.

3 × 3 µm2 AFM images of ion sputtered soda-lime glass surface morphologies with ion fluence varying from a 9.7 × 1017 ions/cm2, b 6.9 × 1018 ions/cm2, c 1.25 × 1019 ions/cm2, and d 2.0 × 1019 ions/cm2 at a fixed ion energy of 1000 eV, respectively. The insets of each AFM image correspond to corresponding 2D-FFTs. The black arrow indicates the direction of ion beam.

It is observed that that at low fluence 9.7 × 1017 ions/cm2, where the wavelength is ~ 53 nm, low-amplitude ripples start evolving with the amplitude below 4 nm (Fig. 7a navy-blue-curve), whereas upon increasing the fluence to 6.9 × 1018 ions/cm2, the amplitude turns out to be 30 – 40 nm and the lateral size of the ripple-like features ~ 90 nm (Fig. 7a magenta-curve). It is observed that with increase in ion fluence, an enormous change in amplitude is visible (Fig. 7a green-curve) such that the amplitude increases to almost four times on increasing the ion fluence value to 1.25 × 1019 ions/cm2, and in addition, the wavelength of the patterns formed is found to be around 280 nm. At the same time, ripple coarsening takes place, and a terrace-like profile starts to evolve, as it is evident from the line profile shown in Fig. 7a green-curve. The lateral size increases to ~ 310 nm at the highest fluence of 2.0 × 1019 ions/cm2 (Fig. 7a red-curve) reported in this work. Although periodicity of the patterns gradually diminishes with ripple coarsening, the lateral extension of the patterns increases with increase in ion fluence as deduced from the AFM images as well as from their corresponding line profiles. The similar kind of behavior in pattern evolution is observed when ion energy is increased from 600 to 1500 eV.

Initially, feeble patterns evolve at lower ion energy, i.e., at 600 eV, where the amplitude remains less than 1 nm and even the periodicity is not regular as observed from Fig. 7b navy-blue-curve. As ion energy is increased to 800 eV, regular ripple pattern starts forming with amplitude around 2 – 3 nm (Fig. 7b magenta-curve). Interestingly, the feature amplitude and lateral extension become close to 40 nm and more than 80 nm, respectively, corresponding to 1000 eV ion energy (Fig. 8b green-curve), as already mentioned also that this energy is the transition point of ripple to terraced-like morphology which develops as ion energy is increased further. Finally, terraced evolves at 1300 eV energy with amplitude varying from 60 – 100 nm as features are not periodic (Fig. 8b red-curve).

Further increasing the energy makes feature extend laterally more than rise in amplitude value. Thus, it can be inferred that with increase in ion fluence as well as ion energy values, the morphology has transformed from parallel-mode ripples to parallel-mode terrace-like structures. The evolution of the surface topography, including detailed quantitative analysis of root-mean-square surface roughness (RMS) and wavelength obtained from the AFM images, is discussed in the Supplementary Information (Fig. C).

In order to better understand the physical origin of terraces on soda-lime glass surface, we analyzed the evolution of the nanoscale slope distribution as a function of the ion fluence, which is shown in Fig. 8. In the figure, we show the histograms of terrace slopes, represented as α, derived from the AFM images representing the pattern obtained at F = 9.7 × 1017 ions/cm2 (Fig. 8(a) blue-curve), F = 6.9 × 1018 ions/cm2 (Fig. 8b black-curve), F = 1.25 × 1019 ions/cm2 (Fig. 8c red-curve), and F = 2.0 × 1019 ions/cm2 (Fig. 8d royal-blue-curve). These distributions highlight certain important effects, first, terrace start evolving after a fluence value 9.7 × 1017 ions/cm2, because at this value of fluence, the curve is symmetrical, signifying the distribution is isotropic, that means no terraces evolved here, but afterward there is appearance of peak which increases with increase in fluence value. Secondly, remarkable differences can be noticed in width and symmetry of the distributions as fluence is increased from 9.7 × 1017 ions/cm2 to 2.0 × 1019 ions/cm2 with the onset of terrace formation. The strong asymmetry of the slope distributions with the appearance of negative tails at higher fluences demonstrates the growth of asymmetry saw tooth-like ripple or what we are calling as terrace profile. As the fluence increases, the asymmetry in slope distribution increases, indicating the dominant role of nonlinear processes in the morphological evolution. Thus, it can be inferred that below the ion fluence value 9.7 × 1017 ions/cm2, morphological evolution remains in the linear regime. Further, with the increase in fluence, the distribution gets split into two peaks for fluences ≥ 6.9 × 1018 ions/cm2, indicating the existence of two slopes, which may arise from the dominance of nonlinear effects (discussed below) in morphological evolution in this regime. One important aspect which we noticed here is that the characteristic slope α, of the selected terraces, identified by the histogram maximum, is not shifting with increment in ion fluence values, rather they are shifting to higher values in y-direction. These observations suggest that additional nonlinear instabilities should be considered which play a significant role in formation of terraces, as soda-lime glass consists of many elements in different ratio and since sputtering of each element is different, so the temporal evolution of surface height is coupled to the composition evolution during the sputter erosion.

Discussion of pattern formation on soda-lime glass with recent models

When a solid surface is bombarded with broad ion beam at oblique incidence angle, parallel-mode ripples develop on the surface which evolves into terraces as time passes. Terraced surface develops with two selected slops because under compressive shocks form. In our work, we studied the nanoscale terraced topographies developed on soda-lime glass when the surface is bombarded with broad ion beam. We have described how the dynamics of terraces evolve on surface with different ion beam parameters. In the discussion of experimental results obtained for soda-lime glass when irradiated with Ar ions, it will be convenient to consider the modified equation by Pearson et al. (1–D case) [57] and Harrison et al. (2–D case) [60] which give the proper qualitative behavior of the terraces formed on soda-lime glass surfaces. However, their model fails to predict some of the morphologies obtained when incidence angle is below or above 45°. In the presented experiments, a wider range of ion beam parameters has been included compared to work presented in [61], where they have considered only angle of incidence variation as their focus was to achieve anisotropic electrical transport properties of the nanopatterned films. The most widely employed model of pattern formation on the surface of solid that is bombarded with an obliquely incident ion beam is AKS equation. But this equation does not produce terraced topographies, however, the recently introduced model by Pearson and Bradley (PB) includes a better approximation to the sputter yield compared to one used in deriving KS equation which yields a cubic nonlinearity, not present in the KS equation [57, 60]. This cubic nonlinearity can lead to terraced topography which coarsens with time, and this is in accordance with the experimental results presented in this work.

The underlying mechanism for terrace formation is similar to that proposed by PB for terrace formation on a solid surface that undergoes amorphization during ion bombardment. Under these approximations, Bradley showed that the evolution of surface height h (x, y, t) can be described by including cubic nonlinear terms. This yields the EOM:

where h (x, y, t) be the height of the surface above point (x, y) in the x-y plane at time t.

The subscripts x, y, t represent partial derivatives, and the coefficients \(\kappa_{1}\), \( \kappa_{2}\), \( B\), \( \lambda_{1}\),\( \lambda_{2}\) depends on ion beam parameters such as ion incidence angle, ion energy, ion species as well as choice of the target material. The physical mechanisms which contribute to first two terms proportional to \({h}_{xx}\) and \({h}_{yy}\) are curvature dependence of the sputter yield and mass redistribution. The third term proportional to \(\nabla^{2} \nabla^{2} h\) results from surface diffusion or ion-induced viscous flow. Finally, the cubic terms in the equation of motion are sputtering and ion implantation. Pearson and Bradley already showed terracing in 1–D by including this cubic nonlinearity term in the EOM. Later they presented simulations in 2–D where they also displayed topographies having terraces, which are similar to what we observe in our experiments for 45° angle of incidence.

Bradley suggested that terraced topographies form when solid surface is bombarded at high angles of incidence, but in our case, terraced topographies are forming at intermediate angles of incidence when bombarded with a broad beam, which is still an open question to answer? But including the third order cubic nonlinearities can explain the formation of terraces on a surface. The formation of ripples during early stages can be explained with the AKS equation or when cubic terms coefficients of above EOM are zero, but there is transition of ripples to terraces as nonlinear effects become dominant as time passes which can be explained with this improved model. In our experiments, this behavior is observed when either the ion energy is increased or when the sample is bombarded for longer duration.

Our motivation for studying this EOM is that ion bombardment of a compound surface like soda-lime glass could produce ripples which with longer fluences leads to formation of terraces which can be explained with the effect of cubic nonlinearity. This EOM is valid under the assumption that target is amorphous or gets amorphized after ion bombardment.

The good agreement between the experimentally observed pattern and results of the continuum equation indicates that the terrace formation is strongly linked to the cubic nonlinearity. Basically, the surface will tend toward a state where most of the surface has a gradient nearly equal to the slope of the gradient and hence surface will have a terrace-like structure. Our experimental work establishes that these ripples have sinusoidal profiles for lower energy and then transition to terraced profiles for higher energy. The numerical integrations presented in the work [57], also reveal that the terraces coarsen as time passes, which is also the case of our present experimental work. Morphologies obtained at 55° or other angles did not develop in simulations of above models or any subsequent models/equations of motion that we have examined, however. As such they represent a challenge to future work.

Application: contact angle measurements

To further explore the applicability of this pattern formation, contact angle measurements were performed at all three ion beam parameters considered in this work, i.e., ion energy, ion fluence and ion incidence angle. The contact angle for the pristine or untreated surface was found to be around 38°, which represents the hydrophilic nature of the soda-lime surface. However, the contact angle becomes ~ 100° after ion irradiation for an optimum value of ion beam parameters which will be described in detail below. There is a transition of surface from the hydrophilic to a hydrophobic one.

The contact angle was measured at two different orientations, i.e., (i) parallel and (ii) perpendicular to the direction of patterns formed on the surface. One can understand well from the schematic diagram in Fig. 9, where a 3D-view of a water droplet sitting on a patterned surface is shown. This 3D AFM image of the soda-lime surface corresponds to the fluence of 1.4 × 1019 ions/cm2 and irradiated at an angle of 45° for ion energy 1000 eV. As the contact interface of water droplet on a rippled surface has different morphologies around its boundary w.r.t to flat surface having same morphology at all places around its boundary, so one can measure the contact angle for a patterned surface at two different orientations because of anisotropy as mentioned above. Also, this anisotropic behavior can be utilized for guiding the water flow on the surface.

Figure 10 shows the variation in the RMS roughness and contact angle with different ion beam parameters. From Fig. 10, it is observed that the contact angle decreases in the parallel to the ripple direction in comparison to the perpendicular direction with all three ion beam parameters. Fig. 10b shows the change in the contact angle as a function of the ion energy when the surface is bombarded with Ar ions with a fixed dose of 6.9 × 1018 ions/cm2.

Variation in RMS roughness and contact angle values, obtained from the corresponding AFM images as a function of a, b ion energy, c, d ion fluence, and (e, f) ion incidence angle, irradiated using Ar+ ions on Soda-lime glass surface. For patterned surfaces, contact angle are plotted for two directions: (i) parallel and (ii) perpendicular to the ripple direction.

The contact angle was found to increase with an increase in energy and then decreases after reaching maximum value at 1000 eV. This is due to the fact that with increase in ion energy, roughness increases (Fig. 10a), and hence contact angle increases, i.e., up to 1000 eV, after which even though the roughness increases but the lateral size of features increases more w.r.t the amplitude (Fig. 7b), thereby there is decrease in contact angle, as contact angle is influenced by many factors including roughness, amplitude, lateral length and the aspect ratio. To check the influence of other ion beam parameters on hydrophobic properties, contact angle measurements were carried out with ion fluence and ion incidence angle as well. Fig. 10d shows the ion dose dependence of the contact angle for soda-lime glass after ion irradiation by 1000 eV Ar+ ions under an ion dose range of 9.7 × 1017 to 2.0 × 1019 ions/cm2 at fixed incidence angle of 45°.

It is clear from the Fig. 10d that the contact angle of the surface increases with an increase in the ion dose, becomes almost constant, and finally decreases with further ion doses of more than 1.4 × 1019 ions/cm2. A maximum contact angle of 101° was obtained on glass surfaces after ion irradiation for ion dose of 9.5 × 1018 ions/cm2. This increase in the contact angle is due to the change in surface roughness after which the features lateral dimension increases w.r.t the amplitude of features and hence the contact angle decreases. Fig. 10f shows the contact angle measurements with variation in ion incidence angle. The contact angle increases up to an ion incidence angle of 45°, after which it decreases due to the amplitude of the features. At ion incidence angle 35°, the amplitude of features formed is higher but not uniform leading to higher aspect ratio (amplitude to wavelength) and hence contact angle such that making the surface hydrophilic (Fig. 10f). For 45°, the features amplitude throughout the surface is uniform and hence the aspect ratio decreases thereby leading to an increase in the contact angle value making the surface hydrophobic in nature. Further on increasing the ion incidence angle of 55°, the amplitude of the features decreases and the surface becomes smooth leading to decrease in the contact angle as well. The surface aspect ratio appears as a crucial/key parameter to control the emergence of hydrophobicity on the nanopatterned surfaces. The contact angle with respect to ion incidence angle shows a different trend when the angle is increased from 30° to higher incidence angles. Basically, the contact angle increases first and then attains a maximum value and thereafter starts decreasing. If we look at the roughness graph which is shown in Fig. 10e, it is observed that the roughness is continuously decreasing with increasing ion incidence angle, so accordingly, contact angle should also decrease, but here other factors like amplitude, periodicity (lateral length) also plays an important role, especially the ratio of amplitude and lateral length (aspect ratio). Moreover, considering the complex composition of soda-lime glass, with silicon (Si) and oxygen (O) being the predominant components, the sputtering behavior is different. With an increase in angle at room temperature, it has been found that the surface gets smoother, which can be attributed to the diffusion of other species that might hinder the propagation of Si and O, resulting in an overall smoother surface. From the line profile of 30° in Fig. 4a, the features lateral length, which is more than 500 nm, is higher in comparison to the amplitude of the features which is around 100 nm, and hence the water droplet would not feel a force and therefore the contact angle is also low. At angle of incidence 35°, the lateral length of the features is around 150 nm and amplitude of the features is around 40 – 60 nm, hence the aspect ratio increases wrt previous angle of incidence, hence the contact angle increases a bit, as their will be some force from the features. Then at ion incidence angle 45°, the contact angle rises to the maximum value because the aspect ratio of amplitude vs. lateral length increases, which means the water droplet will be repelled by the features as their will be more force, also the features are more periodic, hence an equal amount of repulsion from the whole surface is felt by water droplet. Then, as we go on increasing the ion incidence angle, the contact angle reduces again, first of all the amplitude reduces drastically which is an important factor for CA, secondly the features are not periodic at all, and the roughness also decreases suddenly, so combining all three factors the contact angle reduces as we further increase the ion incidence angle. Also, contact angles measured in the parallel direction of the ripple patterns (along the ripples) on these surfaces were always found to be lower than that in the orthogonal direction as the water droplet elongates more in the parallel direction because of the directional force provided by features. Thus, the contact angle measurements reveal the increasing nature of hydrophobicity with evolution of pattern formation. The low wettability of the surfaces before ion irradiation was significantly improved by the irradiation process. So, by using an ion beam of energy 1000 eV irradiated at 45°, ripples formation is regular and resulted in higher contact angle value, deviating from these values on either side results in decrease in contact angle values. Hence contact angle measurement can act as a tool to check whether the surface developed ripple patterns or not as the anisotropy is also enhanced at these parameters. From application point of view, transparency of glass surfaces is very important.

To check if there is any loss in the transparency of the irradiated glass surface, the transmission coefficient of the sample was observed with ellipsometer for a range of wavelengths from ultraviolet to infrared. From Fig. 11, it can be observed that the transmission coefficient remains unchanged for all practical range of solar radiation including ultraviolet, visible, and infrared rays. Thus, it can be concluded that the nanoripples developed on the soda-lime glass surface are responsible for a sharp enhancement of contact angle. The surface which was earlier hydrophilic has now become hydrophobic after ion irradiation. The contact angle varies with different ion beam parameters since the amplitude and wavelength of patterns determines the contact angle.

Conclusions

In this work, we have investigated the dynamic behavior of pattern formation on soda-lime glass surface after Ar irradiation for different ion irradiation conditions. A detailed study on the morphological evolution of pattern formation and their transformation from ripples to terraces with variation in ion beam parameters has been reported. In particular, 1000 eV Ar+ ions were bombarded on soda-lime glass surface at different ion incidence angles varying from 35° – 55° and fluences ranging from 9.7 × 1017 to 2.0 × 1019 ions/cm2. The evolution of patterns with fluence reveals a coarsening and terracing of patterns with the earliest erosion fluence accessible within the experiments. The dimension of the evolved surface nanopatterns plays a key role in determining the wettability of the surface. The experimental conditions in terms of ion energy, ion incidence angle and ion fluence can be used to tune the hydrophobicity of the soda-lime glass surface which is illustrated in this work and correlated with a possible change in the surface roughness and amplitude of the features induced by ion beam sputtering process. Such a one-step process of making surface hydrophobic with no loss of transparency over the entire range of wavelength (400–1000 nm) will be extremely useful for many applications. An attempt was also made by performing numerical simulations to understand the physics governing behind the formation of these features. Understanding the underlying mechanism responsible for terrace formation is a key role to apply and control pattern formation.

References:

Ohwaki T, Taga Y (1990) Changes in hydrophobic properties of glass surfaces by ion implantation. J Vac Sci Technol A: Vac, Surf Film 8:2173–2176. https://doi.org/10.1116/1.577036

Huang W-H, Lin C-S (2014) Robust superhydrophobic transparent coatings fabricated by a low-temperature sol–gel process. Appl Surf Sci 305:702–709. https://doi.org/10.1016/j.apsusc.2014.03.179

Taga Y (1993) Recent progress of optical thin films in the automobile industry. Appl Opt 32:5519. https://doi.org/10.1364/AO.32.005519

Ahsan MdS, Dewanda F, Lee MS, Sekita H, Sumiyoshi T (2013) Formation of superhydrophobic soda-lime glass surface using femtosecond laser pulses. Appl Surf Sci 265:784–789. https://doi.org/10.1016/j.apsusc.2012.11.112

Wang B, Hua Y, Ye Y, Chen R, Li Z (2017) Transparent superhydrophobic solar glass prepared by fabricating groove-shaped arrays on the surface. Appl Surf Sci 426:957–964. https://doi.org/10.1016/j.apsusc.2017.07.169

Lin Y, Han J, Cai M, Liu W, Luo X, Zhang H, Zhong M (2018) Durable and robust transparent superhydrophobic glass surfaces fabricated by a femtosecond laser with exceptional water repellency and thermostability. J Mater Chem A Mater 6:9049–9056. https://doi.org/10.1039/C8TA01965G

Sigmund P (1969) Theory of Sputtering. I. Sputtering Yield of Amorphous and Polycrystalline Targets. Phys Rev 184:383–416. https://doi.org/10.1103/PhysRev.184.383

Martin PJ (1986) Ion-based methods for optical thin film deposition. J Mater Sci 21:1–25. https://doi.org/10.1007/BF01144693

Sawada Y, Taga Y (1983) Inhomogeneous indium tin oxide films prepared by sputtering with multiple targets. Thin Solid Films 110:L129–L132. https://doi.org/10.1016/0040-6090(83)90511-4

Pachchigar V, Ranjan M, Mukherjee S (2019) Role of hierarchical protrusions in water repellent superhydrophobic PTFE surface produced by low energy ion beam irradiation. Sci Rep 9:8675. https://doi.org/10.1038/s41598-019-45132-z

Garg SK, Datta DP, Ghatak J, Thakur I, Khare K, Kanjilal D, Som T (2016) Tunable wettability of Si through surface energy engineering by nanopatterning. RSC Adv 6:48550–48557. https://doi.org/10.1039/C6RA04906K

Liu Y, Hirsch D, Fechner R, Hong Y, Fu S, Frost F, Rauschenbach B (2018) Nanostructures on fused silica surfaces produced by ion beam sputtering with Al co-deposition. Appl Phys A 124:73. https://doi.org/10.1007/s00339-017-1393-4

Flamm D, Frost F, Hirsch D (2001) Evolution of surface topography of fused silica by ion beam sputtering. Appl Surf Sci 179:95–101. https://doi.org/10.1016/S0169-4332(01)00269-0

Rusponi S, Costantini G, Boragno C, Valbusa U (1998) Scaling Laws of the Ripple Morphology on Cu(110). Phys Rev Lett 81:4184–4187. https://doi.org/10.1103/PhysRevLett.81.4184

Hans S, Ranjan M (2022) Emergence of triangular features on ion irradiated silicon (100) surface. Surf Sci 715:121951. https://doi.org/10.1016/j.susc.2021.121951

and D.C. M. Navez, C. Sella, Étude de l’attaque du verre par bombardement ionique, C. R. Acad. Sci. 240 (1962).

Pachchigar V, Gaur UK, A TV, S KP, hans S, Srivastava SK, Rajan M (2022) Hydrophobic to superhydrophobic and hydrophilic transitions of Ar plasma-nanostructured PTFE surfaces. Plasma Proc Polym. https://doi.org/10.1002/ppap.202200037

Luo P, Jaramillo C, Wallum AM, Liu Z, Zhao R, Shen L, Zhai Y, Spear JC, Curreli D, Lyding JW, Gruebele M, Wang W, Allain JP, Z Y (2020) Coherent atomic-scale ripples on metallic glasses patterned by low-energy ion irradiation for large-area surface structuring. ACS Appl Nano Mater 3:12025–12033. https://doi.org/10.1021/acsanm.0c02548

Saini M, Augustine S, Ranjan M, Som T (2020) In-plane optical anisotropy and SERS detection efficiency of self-organized gold nanoparticles on silicon nanoripples: Roles of growth angle and postgrowth annealing. Appl Surf Sci 512:145703. https://doi.org/10.1016/j.apsusc.2020.145703

Chowdhury D, Satpati B, Ghose D (2016) Temperature and high fluence induced ripple rotation on Si (100) surface. Mater Res Express 3:125003

Hans S, Parida BK, Pachchigar V, Augustine S, Saini M, Sooraj KP, Ranjan M (2022) Temperature influence on the formation of triangular features superimposed on nanoripples produced by low-energy ion beam. Surf Interfaces 28:101619. https://doi.org/10.1016/j.surfin.2021.101619

Hans S, Parida BK, Pachchigar V, Augustine S, S KP, Rajan M (2022) Dynamics of nanoscale triangular features on Ge surfaces. Nanotechnology. https://doi.org/10.1088/1361-6528/ac7cf4

Gago R, Vázquez L, Cuerno R, Varela M, Ballesteros C, Albella JM (2002) Nanopatterning of silicon surfaces by low-energy ion-beam sputtering: dependence on the angle of ion incidence. Nanotechnology 13:313. https://doi.org/10.1088/0957-4484/13/3/313

Zhang K, Rotter F, Uhrmacher M, Ronning C, Krauser J, Hofsäss H (2007) Ion induced nanoscale surface ripples on ferromagnetic films with correlated magnetic texture. New J Phys 9:29–29. https://doi.org/10.1088/1367-2630/9/2/029

Madi CS, Bola George H, Aziz MJ (2009) Linear stability and instability patterns in ion-sputtered silicon. J Phys: Condens Matter. 21:224010. https://doi.org/10.1088/0953-8984/21/22/224010

Keller A, Facsko S (2010) Ion-Induced nanoscale ripple patterns on si surfaces: theory and experiment. Materials 3:4811–4841. https://doi.org/10.3390/ma3104811

Keller A, Facsko S, Möller W (2008) Minimization of topological defects in ion-induced ripple patterns on silicon. New J Phys 10:063004. https://doi.org/10.1088/1367-2630/10/6/063004

Keller A, Roßbach S, Facsko S, Möller W (2008) Simultaneous formation of two ripple modes on ion sputtered silicon. Nanotechnology 19:135303. https://doi.org/10.1088/0957-4484/19/13/135303

Macko S, Frost F, Ziberi B, Förster DF, Michely T (2010) Is keV ion-induced pattern formation on Si(001) caused by metal impurities? Nanotechnology 21:085301. https://doi.org/10.1088/0957-4484/21/8/085301

Teichmann M, Lorbeer J, Ziberi B, Frost F, Rauschenbach B (2013) Pattern formation on Ge by low energy ion beam erosion. New J Phys 15:103029. https://doi.org/10.1088/1367-2630/15/10/103029

Teichmann M, Lorbeer J, Frost F, Rauschenbach B (2014) Ripple coarsening on ion beam-eroded surfaces. Nanoscale Res Lett 9:439. https://doi.org/10.1186/1556-276X-9-439

Fouckhardt H, Steingoetter I, Brinkmann M, Hagemann M, Zarschizky H, Zschiedrich L (2007) nm-and μm-scale surface roughness on glass with specific optical scattering characteristics on demand. Adv Optoelectron 2007:1–7

Teichert C, de Miguel JJ, Bobek T (2009) Ion beam sputtered nanostructured semiconductor surfaces as templates for nanomagnet arrays. J Phys: Condens Matter 21:224025. https://doi.org/10.1088/0953-8984/21/22/224025

Carter G, Vishnyakov V (1996) Roughening and ripple instabilities on ion-bombarded Si. Phys Rev B 54:17647–17653. https://doi.org/10.1103/PhysRevB.54.17647

Erlebacher J, Aziz MJ, Chason E, Sinclair MB, Floro JA (1999) Spontaneous pattern formation on ion bombarded Si (001). Phys Rev Lett 82:2330

Gago R, Vázquez L, Cuerno R, Varela M, Ballesteros C, Albella JM (2001) Production of ordered silicon nanocrystals by low-energy ion sputtering. Appl Phys Lett 78:3316–3318. https://doi.org/10.1063/1.1372358

Mayer TM, Chason E, Howard AJ (1994) Roughening instability and ion-induced viscous relaxation of SiO 2 surfaces. J Appl Phys 76:1633–1643. https://doi.org/10.1063/1.357748

Habenicht S (2001) Morphology of graphite surfaces after ion-beam erosion. Phys Rev B 63:125419. https://doi.org/10.1103/PhysRevB.63.125419

Datta A, Wu Y-R, Wang YL (2001) Real-time observation of ripple structure formation on a diamond surface under focused ion-beam bombardment. Phys Rev B 63:125407. https://doi.org/10.1103/PhysRevB.63.125407

Datta D, Bhattacharyya SR, Chini TK, Sanyal MK (2002) Evolution of surface morphology of ion sputtered GaAs(). Nucl Instrum Methods Phys Res B 193:596–602. https://doi.org/10.1016/S0168-583X(02)00860-1

Zhang Z, Wang L, Wang J, Jiang X, Li X, Hu Z, Ji Y, Wu X, Chen C (2012) Mesoporous Silica-Coated Gold Nanorods as a Light-Mediated Multifunctional Theranostic Platform for Cancer Treatment. Adv Mater 24:1418–1423. https://doi.org/10.1002/adma.201104714

Ruth M, Meier C (2013) Structural enhancement of ZnO on SiO 2 for photonic applications. AIP Adv 3:072114. https://doi.org/10.1063/1.4815974

Yu X-F, Chen L-D, Li M, Xie M-Y, Zhou L, Li Y, Wang Q-Q (2008) Highly efficient fluorescence of NdF 3 /SiO 2 Core/Shell nanoparticles and the applications for in vivo NIR detection. Adv Mater 20:4118–4123. https://doi.org/10.1002/adma.200801224

Ren F, Jiang CZ, Wang YH, Wang QQ, Wang JB (2006) The problem of core/shell nanoclusters formation during ion implantation. Nucl Instrum Methods Phys Res B 245:427–430. https://doi.org/10.1016/j.nimb.2005.11.052

Keller A, Facsko S, Möller W (2009) Evolution of ion-induced ripple patterns on SiO2 surfaces. Nucl Instrum Methods Phys Res B 267:656–659. https://doi.org/10.1016/j.nimb.2008.11.044

Kumar M, Datta DP, Basu T, Garg SK, Hofsäss H, Som T (2018) Temporal evolution on SiO 2 surface under low energy Ar + -ion bombardment: roles of sputtering, mass redistribution, and shadowing. Journal of Physics: Condensed Matter 30:334001. https://doi.org/10.1088/1361-648X/aad1b8

Srivastava SK, Ganesan K, Gangopadhyay P, Panigrahi BK, Nair KGM, Tyagi AK (2014) High energy ion irradiation induced surface patterning on a SiO 2 glass substrate. Nucl Instrum Methods Phys Res B 338:89–94. https://doi.org/10.1016/j.nimb.2014.08.003

Giordano MC, di Sacco F, Barelli M, Portale G, Buatier de Mongeot F (2021) Self-Organized Tailoring of Faceted Glass Nanowrinkles for Organic Nanoelectronics. ACS Appl Nano Mater 4:1940–1950. https://doi.org/10.1021/acsanm.0c03290

Toma A, Buatier de Mongeot F, Buzio R, Firpo G, Bhattacharyya SR, Boragno C, Valbusa U (2005) Ion beam erosion of amorphous materials: evolution of surface morphology. Nucl Instrum Methods Phys Res B 230:551–554. https://doi.org/10.1016/j.nimb.2004.12.099

Umbach CC, Headrick RL, Chang K-C (2001) Spontaneous Nanoscale Corrugation of Ion-Eroded <math display="inline"> <mrow> <msub> <mrow> <mi>SiO</mi> </mrow> <mrow> <mn>2</mn> </mrow> </msub> </mrow> </math> : The Role of Ion-Irradiation-Enhanced Viscous Flow. Phys Rev Lett 87:246104. https://doi.org/10.1103/PhysRevLett.87.246104

Sigmund P (1973) A mechanism of surface micro-roughening by ion bombardment. J Mater Sci 8:1545–1553. https://doi.org/10.1007/BF00754888

Bradley RM, Harper JME (1988) Theory of ripple topography induced by ion bombardment. J Vac Sci Technol A: Vac, Surfaces Films 6:2390–2395. https://doi.org/10.1116/1.575561

Makeev MA, Cuerno R, Barabási A-L (2002) Morphology of ion-sputtered surfaces. Nucl Instrum Methods Phys Res B 197:185–227. https://doi.org/10.1016/S0168-583X(02)01436-2

Castro M, Cuerno R, Vázquez L, Gago R (2005) Self-organized ordering of nanostructures produced by ion-beam sputtering. Phys Rev Lett 94:016102. https://doi.org/10.1103/PhysRevLett.94.016102

Sharath T, Bradley RM (2022) Theory of the nanoscale surface ripples produced by ion irradiation of a miscut (001) gallium arsenide surface. Phys Rev E 105:024801. https://doi.org/10.1103/PhysRevE.105.024801

Ou X, Heinig K-H, Hübner R, Grenzer J, Wang X, Helm M, Fassbender J, Facsko S (2015) Faceted nanostructure arrays with extreme regularity by self-assembly of vacancies. Nanoscale 7:18928–18935. https://doi.org/10.1039/C5NR04297F

Pearson DA, Bradley RM (2015) Theory of terraced topographies produced by oblique-incidence ion bombardment of solid surfaces. J Phys: Condens Matter 27:015010. https://doi.org/10.1088/0953-8984/27/1/015010

Loew KM, Bradley RM (2019) Effect of dispersion on the nanoscale patterns produced by ion sputtering. Phys Rev E 100:012801. https://doi.org/10.1103/PhysRevE.100.012801

Horcas I, Fernández R, Gomez-Rodriguez JM, Colchero J, Gómez-Herrero J, Baro AM (2007) WSXM: a software for scanning probe microscopy and a tool for nanotechnology. Rev Sci Instrum 78:13705

Harrison MP, Pearson DA, Bradley RM (2017) Emergence and detailed structure of terraced surfaces produced by oblique-incidence ion sputtering. Phys Rev E 96:032804. https://doi.org/10.1103/PhysRevE.96.032804

Barelli M, Giordano MC, Gucciardi PG, Buatier de Mongeot F (2020) Self-Organized Nanogratings for Large-Area Surface Plasmon Polariton Excitation and Surface-Enhanced Raman Spectroscopy Sensing. ACS Appl Nano Mater 3:8784–8793. https://doi.org/10.1021/acsanm.0c01569

Acknowledgment

We thank Prof R Mark Bradley from Colorado State University, United States, for helpful discussions.

Funding

Open access funding provided by Department of Atomic Energy.

Author information

Authors and Affiliations

Contributions

Sukriti Hans contributeed to conceptualization, methodology, formal analysis, writing–original draft. Basanta Kumar Parida, K.P. Sooraj, Vivek Pachchigar and Sebin Augustine contributed to investigation and formal analysis. Mukesh Ranjan contributed to conceptualization, writing—review & editing, supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: N. Ravishankar.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hans, S., Parida, B.K., Augustine, S. et al. Anisotropic wettability transition on nanoterraced glass surface by Ar ions. J Mater Sci 59, 14205–14223 (2024). https://doi.org/10.1007/s10853-024-10039-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-10039-2