Abstract

As tellurides and selenides of Bismuth are extensively used thermoelectric materials in the low-temperature range with refrigeration application, A concerted effort is put forth to boost the ZT by co-doping the pristine Bi2Se3 with antimony (Sb) on cation end and tellurium (Te) on anion side of the compound. The double sintered solid-state reaction method is employed in the preparation of Bi2Se3 and (Bi1−xSbx)2Se2.7Te0.3 polycrystalline pellets, with x = 0.02, 0.04, and 0.06. The sample exhibits a rhombohedral structure with the space group of R \(\overline{3 }\) m. FESEM and EDAX analysis are used to confirm surface morphology and elemental composition of the produced samples. The thermoelectric measurements for the pristine and co-doped samples were conducted by the physical property measurement system as well as a considerable increase in the Seebeck coefficient of − 115 µV/K is observed for 0.02 doping of the Sb which is 4.2 times greater than as for pristine (S = − 28 µV/K). Higher concentration doping (x = 0.04, 0.06) has not reflected any Seebeck coefficient advancement. In contrast, the lowest total thermal conductivity at a low-temperature regime (< 50 K) is observed for x = 0.06 doping concentration which at near room temperature increases beyond the pristine thermal conductivity; whereas, x = 0.02, 0.04 doping concentration shows a decrement in total thermal conductivity at low, at room temperature region the values are almost equivalent to that of pristine. The co-doped samples’ electrical resistivity is substantially less than pristine sample. The highest power factor of 3 × 10–4 µW/mK2 is obtained for the x = 0.02 sample. The highest ZT value for the x = 0.02 sample is almost 28 times more than a pristine sample. We conducted a study where we combined experimental and DFT methods to investigate thermoelectric properties incorporated into pristine and doped with antimony and tellurium on Bi2Se3. We have employed this combination to investigate the partial density of states, Seebeck coefficient, power factor using the Boltzmann transport equation. Theoretical thermoelectric data were derived and compared to experimental observations. Hence, using combined experimental and theoretical investigations helps to predict with higher accuracy of thermoelectric properties of semiconducting materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Renewable energy initiatives have heightened fascination with more sustainable energy generation via thermoelectric materials as a heat-to-electricity converter that is an ecologically friendly method. Among the several technologies employed to achieve these requirements, thermoelectric energy is of particular importance, because of its distinct characteristics. Because they are adept at both directly and reversely converting heat into electricity, thermoelectric materials have a substantial impact on power generation and cooling. To improve the efficiency of power generators as well as Peltier coolers, researchers have explored diverse materials. Several bulk and single-crystal thermoelectric materials are being examined for extracting the best power efficiencies. The ZT is the thermoelectric figure of merit, that controls the thermoelectric material’s effectiveness and is achieved by the formula \(\text{ZT}= \frac{{S}^{2}T}{k\rho }\), where S—the Seebeck coefficient, T—the absolute temperature, κ—the thermal conductivity, and ρ—the electrical resistivity of the material. To search for the highest ZT value in the expected operating temperature spectrum, the dopants, composition, and material synthesis technique need to be optimized. In the quest to attain high ZT, the focus has shifted to highly promising low-dimensional or nanostructural materials. However, reduced dimensionality in thermoelectric materials causes certain restrictions. The high fabrication cost and complexity of nanostructural thermoelectric materials give rise to the demand for low-cost polycrystalline materials. Heat-carrying phonons can be scattered by bulk polycrystals with several grain boundaries, greatly reducing thermal conductivity κ, but it deteriorates the electrical conductivity σ.

Low-temperature thermoelectric material mainly composed of Bi2Te3, Bi2Se3, and Sb2Te3. Among these Bi2Te3 is particularly well studied and has been a commercialized material for a long time due to its high power factor and low thermal conductivity. Bi2Se3 also belongs to the same chalcogenide thermoelectric material group but due to its poor thermoelectric performance, this material has attained less attention. Bi2Se3 has undergone much less consideration as a thermoelectric material and has very little thermoelectric data. Considering the scarcity of Te, finding Bi2Te3 alternatives, as attempted in this work, is of importance for practical applications. Due to the conflicting dependency of thermoelectric parameters such as the Seebeck coefficient, electrical conductivity, and thermal conductivity, it is a challenge to improve the thermoelectric properties of these materials[1], Band engineering, nanostructuring [2], and doping are a few of the methods to improve the TE performance of these materials. Therefore, it was opted to dope it with an appropriate concentration of dopant material. The anion side doping can enhance the Seebeck coefficient but cannot help much in enhancing the electrical conductivity for this to enhance the numerator the Sb dopant which has high carrier concentration has been used. This co-doping technique of doping on both anion and cation site using Solid-state method is the novelty of this manuscript.

Dopant additions have significantly impacted the thermoelectric chalcogenides electron density distribution [3]. Furthermore, doping can have an impact on decreasing the thermal conductivity of the lattice by introducing flaws and scattering centers. However, the amount of doping should be adjusted in order to increase electrical conductivity with no effect on the Seebeck coefficient [4]. Besides, doping increases carrier concentration, which relates to improved electrical conductivity. However, the influence of doping on boosting carrier concentration fails to make up for the reduction in carrier mobility; electrical conductivity won’t be enhanced. Consequently, the doping level should be optimized for a certain value where raising the carrier concentration outweighs the alloying effect. Doping also has a considerable influence on altering the operating temperature that determines the highest ZT value to be obtained. Furthermore, the Seebeck coefficient and electrical conductivity must be enhanced [5, 6]. The scattering of phonons across the boundary lowers thermal conductivity, whereas the filtration of low-energy carriers raises the power factor.

Apart from increasing the ZT.value, it is also crucial for thermoelectric materials to be thermally stable. The increase in the temperature could change the material properties, such as the composition and microstructure. Thermoelectric materials with constituents such as Te, Sb, and Se are the most volatile substances having the risk of becoming sublimated at high temperatures. Also, oxidation can lead to degradation of these materials. The problem concerned with thermal stability has yet to be fully understood, but it may depend upon the modes and methods associated with the fabrication. Thermal stability of these materials is investigated using thermogravimetry and DSC [7].

The p-type Bi–Sb–Te and n-type Bi–Te–Se bismuth telluride-based alloys are among the most effective thermoelectric compounds at temperatures below 350 K. Thus far, greater conversion efficiencies have been linked to p-type alloys, leaving an n-type Bi–Te–Se system as a prospective possibility. An array of investigations revealed that strongly doped semiconductors exhibit the most powerful power factor and the lowest thermal conductivity, making them among the finest efficient bulk thermoelectric materials. The anharmonicity of the chemical bonds is critical in restricting the thermal conductivity of the lattice [8, 9]. Several strategies have been followed to decouple the parameters and attain a high power factor, low thermal conductivity, or a mix of the two. We have successfully achieved a reduction in the thermal conductivity and electrical resistivity of 7.5 and 9 times, respectively, in In and Te co-doped Bi2Se3 TE systems [10, 11]. Similarly, increased thermoelectric figure of merit and power factor is observed in the Bi2Se3 system introducing Sn and Te co-doping [12].

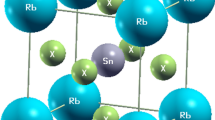

The present study reported the synthesis of Bi2Se3 doped with antimony and simultaneously co-doped with tellurium retaining the preferred crystallographic orientation. Bi2Se3 is an n-type semiconductor with a short bandgap (0.3 eV) narrow bandgap with a rhombohedral anisotropic crystal structure belonging to the R \(\overline{3 }\) m space group, with 5 atoms packed within unit cell forming a quintuple structure like Se(1)–Bi–Se(2)–Bi–Se(1). Doped with different concentrations of Sb and Te in Bi2Se3 has been extensively researched since the doping procedure generally leads to the enhanced thermoelectric performance of Bi2Se3 [13].

Some of the most often utilized procedures for the synthesis of Bi2Se3 are solid-state reaction, melt growth, Hydrothermal or solvothermal, Sol–Gel etc. Solution-based procedures provide precise control over reaction parameters such as temperature, pressure, and chemical environment, resulting in higher product quality and less contamination due to the dissolution of precursor components in solvent. These approaches also provide greater control over the end product’s morphology, size, and nanostructure. Despite these many advantages requirement of numerous phases such as synthesis, solvent removal, and drying, complicating the process. The choice of solvent has a considerable impact on the reaction kinetics and product features, necessitating careful optimization; while, possible impurities from solvents or reagents might alter final product purity and attributes. Furthermore, solution-based techniques may include specialized equipment like an autoclaves or vacuum systems, which adds to the cost and complexity of synthesis. Solid-state reactions, on the other hand include mixing and heating of precursor elements, are distinguished by their simplicity and suitability for mass production in a variety of materials such as ceramics, intermetallic complexes, and certain oxides. These reactions produce highly crystalline and pure materials, whose compositions can be adjusted by varying precursor stoichiometry.

In this work, samples of Bi2Se3 and (Bi1−xSbx)2Se2.7Te0.3 with x = 0.02, 0.04, and 0.06 were created to investigate the impact of Sb on the physical properties of bismuth selenide prepared using the conventional solid-state-reaction technique. Among all the studied compositions, (Bi0.98Sb0.02)2Se2.7Te0.3 possessed the highest power factor of 3 × 10–4 µW/mK2 at 300 K. This work aims to explore the most suitable thermoelectric material for room temperature applications.

Experimental details

Synthesis of polycrystals

Precursors such as bismuth (99.5%), antimony (99.5%), selenium (99.9%), and tellurium (99.9%) were used as raw materials. Bi2Se3 and (Bi1−xSbx)2Se2.7Te0.3 (x = 0.02, 0.04, and 0.06) samples were prepared by the solid-state reaction technique. The initial components were blended in a stoichiometric ratio and mixed in an agate mortar for 2 h. The powder obtained after the intense grinding undergoes palletization with a compression pressure of 5 tons. The dimensions of the pellets are 10 mm × 1 mm × 5 mm. The pellets were contained within a quartz tube with a 10–3 torr vacuum and sintered at 130 °C for 24 h. The pellets obtained were ground again in the agate mortar for 1 h to increase compound homogeneity and purity. The powder was again palletized and sintered under the same conditions described above.

Characterization

The X-ray diffraction (XRD) study was carried out using a powder X-ray diffractometer (Rigaku Miniflex with CuKα with λ = 1.5406 Å) in the 2θ range of 20°–80° with a scanning rate of 2°/min. The X-ray diffraction of the sample confirms the purity, crystallinity, dominated phase, and formation of the compounds. The field emission scanning electron microscope (Carl Zeiss Sigma) inspects the surface morphological feature with 50 KX magnification. The chemical composition of the grown sample was examined by energy dispersive X-ray analysis (EDAX) using EVO MA18 with Oxford EDS (X-act) [14]. The van der Pauw method was used to assess the Hall effect and quantify the carrier concentration and mobility of the tested samples at room temperature. Electrical resistivity measurements in the 10–350 K temperature range were measured using the standard four-probe method in the physical property measurement system (PPMS). Also, Seebeck coefficient and thermal conductivity tests were performed simultaneously using PPMS.

Results and discussion

Powder X-ray diffraction

Figure 1a displays the XRD pattern obtained for the Sb and Te co-doped samples and shows the effect on the crystallite size and lattice parameters. The systematic increase or decrease in crystallite size depends upon the ionic radius of the doping element or concentration of the same [13]. For the Sb-doped samples, the characteristic diffraction peaks were observed, indicating a strong orientation in the (0 1 5) plane. The rest of the crystalline planes appear at different relative intensities of the powder XRD pattern. The sharp peaks in the XRD profiles signify the good crystallinity of the (Bi1−xSbx)2Se2.7Te0.3 series. A shift of the intensity peak (0 1 5) was observed due to doping. Figure 1b shows a minor shifting of XRD peak patterns to the lower angle side of 2θ from Bi2Se3 to (Bi1−xSbx)2Se2.7Te0.3 except (Bi0.94Sb0.06)2Se2.7Te0.3. In XRD, the increase in lattice parameter indicates a lower angle shift of the peak and vice versa. It is well-known that the lattice parameters decrease upon the formation of structural vacancies and can also be explained by atomic radii. Therefore, the peak shift in XRD also depends upon the dopant size [11].

The increase and decrease in crystallite size can be understood by the variation in the dopant ionic radius, i.e., Bi (230 pm), Sb (206 pm), Se (190 pm), and Te (210 pm). Due to the greater size of Te, its substitution into Se increases the crystallite size. As Sb replaces the cation site of Bi, it causes a reduction in crystallite size due to its smaller ionic radius than Bi. Hence, there is an overall increment in the crystallite size for the x = 0.02 sample as the effect of Te substitution overwhelms the Sb substitution. As a result, increasing the lattice parameter is observed, reflecting the lower angle shift of the (0 1 5) plane. The further substitution of Sb into the Bi site is expected to reduce the lattice parameter for the x = 0.04 sample further; however, a leftward shift of the (0 1 5) peak is observed. Further addition of Sb increases the crystallite size (x = 0.06), and the lattice parameter decreases with a rightward shift of the (0 1 5) peak. The increased crystallite size may be due to the increased c parameter resulting from the increased tensile strain. On the other hand, the reduced lattice parameter for the x = 0.04 sample is presumably credited to the structural vacancies.

The Williamson–Hall method is used to calculate the crystallite size (D) and strain (ε) using the formula.

where β—full width at half maximum intensity in radians, λ (1.54 nm)—X-ray wavelength, θ—diffraction angle, D—crystallite size, and ε—strain. The Expo 2014 software used for the Rietveld refinement of the structures (Fig. 2) was performed to obtain RP (profile factor), Rep (expected profile factors), Rwp (weighted profile factor), χ2 (the goodness factor), and the outcomes are depicted in Table 1. Based on XRD data analysis, it has been observed that the samples belong to the R \(\overline{3 }\) m space group and exhibit rhombohedral crystal structure.

Field emission scanning electron microscopy (FESEM) and energy dispersive X-ray analysis (EDAX)

The FESEM study shows the surface morphology of Bi2Se3 and the Sb and Te co-doped samples. In Fig. 3a, the grain boundaries are visible with uniformity. With Sb and Te doping in the matrix of bismuth selenide, the surface morphology of studied samples shows flake-like features with increased porosity and white patches at the boundaries (Fig. 3b–d), presumably due to evaporation of highly volatile Se in the samples during the sintering process. It is also due to the presence of unreacted dopants in the compound. As it is difficult to achieve uniform mixing of the precursors in solid-state reaction which may lead to non-uniform distribution of the dopant material resulting into distorted surface morphology like the appearance of white patches [15]. The co-doping of Sb and Te might alter the precipitation rate by the diffusion of atoms, and the particles agglomerate wherever possible at point imperfections in the interstitials. Partial evaporation of selenium causes a decrease in the concentration of vacancies, resulting in a variation in the density of the material. The density and percent porosity of the material is shown in Table 2. The surface area and porosity analyzer (BET) are used to evaluate the surface area and pore volume; whereas, porosity is evaluated using ImageJ software. Table 2 shows the addition dopants causes an increase in porosity. The increase in porosity creates additional phonon scattering sites [16], which lowers the lattice thermal conductivity. It does, however, has an unfavorable effect on electrical transportation. This is supported by the Seebeck coefficient plot, which shows that a modest amount of dopant increases the Seebeck coefficient at first. However, increasing dopant concentration, associated with higher porosity, reduces the Seebeck coefficient. The chemical composition of samples was examined by EDS analysis and shown in Fig. 4 below. The EDS analysis of the pristine sample shows the presence of Bi and Se elements, and (Bi1−xSbx)2Se2.7Te0.3 shows the presence of Te along with Bi, Sb, and Se. The elemental compositions of the prepared samples are shown in Table 3 below.

Thermal analysis

DTA and DSC are used to investigate thermal phenomena such as solid phase transformation, glass transition, crystallization, and melting [17]. Bi2Se3 and (Bi1−xSbx)2Se2.7Te0.3 samples in the form of dense powders were used for DTA or DSC measurements. Commercial DSC instruments can perform phase-shifting measurements in microgram samples. Platinum and gold crucibles are utilized as samples as well as reference holders. The pans are tightly closed to prevent evaporation from changing the sample bulk. These two strategies are very beneficial in characterizing polymeric and inorganic materials.

The TG–DTA curve of Bi2Se3 (Fig. 5a) reveals a 7.2% overall weight decrease. The material underwent oxidation due to exposure to the environment, resulting in an initial weight loss of 1.3%. It is found that the original substance is stable up to 600 °C till it reaches its melting point. The endothermic peak of crystallization can be seen on the DTA curve at around 225 °C, the first exothermic melting peak at about 270 °C, and the second endothermic decomposition peak at about 610 °C. Figure 5b of (Bi0.98Sb0.02)2Se2.7Te0.3, after the doping of Sb and Te, shows stability till 300 °C after the decomposition of the compound around 450 °C with the weight loss of about 37.7%. The material is stable till 670 °C and decomposes with a 12.4% weight loss. A total weight loss of 50.1% is observed for this sample. The DTA curve of the same compound shows a crystallization peak at 225 °C, similar to the pristine sample, and a melting point peak at 270 °C. The first and second decomposition peaks are observed at 450 °C and 670 °C, which matches the TGA curve. Figure 5c shows a similar trend of the TG curve with stability till 250 °C; beyond it, the material starts decomposing with a weight loss of about 28.9% till 440 °C. The decomposed material remains stable till 600 °C then further decomposes at around 740 °C with a weight loss of 8.9%. A total weight loss of 37.8% is observed for 4% doping of Sb. The DTA plot confirms the TG plot with the crystallization peak at 225 °C and the melting peak at 270 °C. The first and second decomposition peaks are observed at 450 °C and 670 °C. Figure 5d shows the stability of (Bi0.94Sb0.06)2Se2.7Te0.3 till 225 °C, after which the material shows decomposition at ~ 450 °C and then remains stable till 650 °C and decomposes further at around 740 °C. A total weight loss of 47.8% is observed for this sample. The DTA curve agrees with the TGA curve, showing the crystallization peak at 225 °C and the melting point peak at 270 °C. The 3-decomposition curve at 500 °C, 625 °C, and 675 °C is observed, which matches the TG curve results. These observations indicate that the studied samples can sustain till 200–250 °C and can be operated in this temperature range.

Hall measurements

The electrical resistivity of the material being studied was measured using the van der Pauw method. The Hall coefficient, mobility, and carrier concentration at room temperature were measured using the Hall effect method with sample dimensions of about 5 mm × 5 mm × 1 mm. The four-point probes of the van der Pauw method were positioned around the sample’s perimeter to derive an average electrical resistivity of the studied material. Two sets of measures were taken to determine the carrier concentration of the samples, one with a magnetic field in the + ve z-direction and one with a − ve z-direction. The difference in the voltages for positive and negative magnetic fields needs to be corrected.

The Hall voltage is given by,

The carrier concentration is derived using the following equation:

Table 4 shows the carrier concentration, Hall mobility, and electrical resistivity values for the as-prepared samples at room temperature. It is noted that the increase in carrier concentration concerning doping concentration and the reduction in electrical resistivity may result in a higher power factor in doped samples compared to the pristine Bi2Se3.

Bi2Se3 due to its high thermal conductivity (κ), low charge carrier mobility, and low Seebeck coefficient (α) is considered a poor thermoelectric material. Among these low thermal conductivity is the highest drawback of these materials which can be overcome by enhancing the thermal conductivity by nanostructuring route [18]. But by considering the synthesis by simple and scalable method the solid-state reaction technique is opted which produces enormous grain boundaries for phonon scattering which helps to reduce the thermal conductivity of the material.

Antimony is found to be a good candidate for reducing the lattice thermal conductivity by increasing the phonon vibrations; therefore, the study has been considered by doping the Bi2Se3 with Sb as well as Te. Uniform doping of Sb enhances electrical conductivity in the material by increasing the carrier concentration. Te which is mainly related to creating vacancy is expected to enhance the Seebeck coefficient and reduce thermal conductivity. By balancing electron and hole concentrations, simultaneous Sb and Te doping optimizes the material for thermoelectric applications.

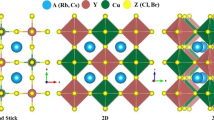

Computational details

The Quantum espresso code [19] was used for density functional calculations for pristine Bi2Se3 with antimony (Sb) on cation end and tellurium (Te) on anion side having rhombohedral crystal structure with the space group (R \(\overline{3 }\) m). The original structural parameter was optimized from the observed experimental data of prepared samples. The inclusion of van der Waals (vdW) interaction in the structure of Bi2Se3 has been taken into account using the Ortmann–Bechstedt–Schmidt (OBS) schemes [20, 21]. In this study, we employed the Hubbard adjustment to the Local Density Approximation (LDA+U) for calculating the band structure. Following the convergence test, a cutoff energy of 350 eV and a k-point grid of 3 × 3 × 3 were selected. The forces acting on the atoms were reduced to less than 0.03 eV/Å, the greatest movement of the ions was limited to 0.001 Å, and the overall stress on the system was lowered to 0.05 GPa. Following optimization, the electronic characteristics, including the partial density of states (DOS), were computed (see Fig. 6). We used the tetrahedron method with a 10 × 10 × 10 denser k-point mesh. We have integrated the Quantum Espresso package with the BoltzTraP code to compute the thermoelectric characteristics [22]. The BoltzTraP algorithm utilizes the principles of the Boltzmann theory to compute several values that are reliant on the density of states, including electronic thermal conductivity (ke). This is done by employing the constant time approximation and the rigid band approximation (RBA). The thermoelectric properties comprise the Seebeck coefficient S, and power factor with experimental investigations. From DFT calculations we have achieved a bandgap of 0.55 eV and 0.68 eV for pure Bi2Se3 and doped Bi2Se3, respectively, using GGA-PBEsol approximation, which is in the same order as experimental findings. The increase in the energy band gap from DFT calculation can also be correlated to the increase in the Seebeck coefficient from the thermoelectric measurement, which can also be proved by the Goldsmid-Sharp relation of Eg = 2e|Smax|Tmax stating increase in Seebeck coefficient would increase the energy bandgap of the material.

Electrical resistivity

The vast majority of thermoelectric substances include doped semiconductors having carrier concentrations ranging from 1018 to 1020 cm−3. The amount of doping affects the carrier density of materials. The enhanced conduction of electricity is indicated by the higher charge mobility. High ZT values are achievable in high-temperature thermoelectric materials but are difficult at low temperatures because impurity scattering predominates [23, 24]. As seen in Fig. 7, the electrical resistivity of the doped samples shows a significant reduction compared with the pristine Bi2Se3. The low value of electrical resistivity of about 0.2 × 10–4 Ωm is obtained for 4% Sb doping at 300 K. This finding could be addressed qualitatively by assuming that integration of Sb atoms into the Bi lattice reduces native defects, i.e., a decline in the anion sublattice Vse vacancy concentration and antisite defects BiSe. It has been concluded from the analysis considering the dependencies of ln(RHσ) versus (lnT) at the low-temperature range that the transport properties of the (Bi1−xSbx)2Se2.7Te0.3 can be explained through the combined scattering process of free carriers on acoustic phonons and ionized impurities [25]. For the x = 0.06 sample, an increase in electrical resistivity is observed, presumably due to the substitution beyond a certain concentration, known as the alloy limit. The addition of atoms beyond this limit would disrupt the crystallinity of the structure and result in high electrical resistivity.

Thermal conductivity

The thermoelectric effectiveness of TE materials is capable of being significantly enhanced if thermal conductivity is decreased to the best-optimized amount. In crystalline solids, electronic thermal conductivity (κe) and lattice thermal conductivity (κL) are the two components that comprise total thermal conductivity (κ) [26] and are given by κ = κe + κL. The total thermal conductivity of the prepared samples are displayed in Fig. 8a indicating a significant drop in the total thermal conductivity from 3.7 to 2.3 W/m K in the low-temperature range of 10–125 K. Beyond 125 K, total thermal conductivity increased due to increased lattice thermal conductivity in the materials. The minimum value of total thermal conductivity is observed for the compound with 6% doping of Sb in the low-temperature region (10–100 K), beyond which it exceeds the values compared to the pristine and doped compounds with x = 0.02 and 0.04. The lowest value for total thermal conductivity at room temperature is observed for the 2% doped compound, with a value of about 2.25 W/m K, similar to the value of the pristine compound. We conclude here that the incorporation of Sb decreases the lattice parameter; while, the deficiency of Se vacancies leads to a rise in total thermal conductivity at high temperatures [18].

The electronic thermal conductivity is expressed using the Weideman-Franz law: κe = LσT, where L and T are the Lorentz number (L = 2.45 × 10−8 WΩK−2) and absolute temperature, and σ stands for electrical conductivity, respectively. It is well-known that the electronic thermal conductivity is influenced by the carrier concentration in semiconductors, as the κe increases when the carrier concentration is high. Figure 8b shows an increase in the electronic thermal conductivity near room temperature from 0.05 W/m K (pristine) to 0.15 W/m K (2% doping), then to 0.40 W/m K (4% doping) as a result of a surge in the carrier concentration (Table 2). However, a decrease in the electronic thermal conductivity is seen for 6% doping, most likely due to enhanced point-defect scattering. In contrast, the lattice thermal conductivity κL is almost without regard to the carrier concentration of studied compounds. As the lattice thermal conductivity comprises relaxation times from the harmonic and anharmonic terms below the Umklapp peak, the harmonic terms dominate. At low temperatures, the impurity scattering takes precedence and reduces the lattice thermal conductivity [8]. Materials with an electron mean free path shorter than the phonon mean free path can minimize the lattice thermal conductivity without compromising the electrical transport. Therefore, a structure with parameters between the electron and phonon mean free paths can exhibit efficient phonon scattering to reduce heat conductivity while maintaining electrical conductivity [27, 28]. Therefore, inserting the Sb atom in Bi2Se3 is expected to inhibit phonon vibration and reduce the lattice thermal conductivity. Based on the reduced atomic dimensions, Sb is appropriate for use as an intercalant in Bi2Se3 layers. Rattling is caused by the presence of Sb atoms amid the van der Waals gaps, which lowers thermal conductivity. The difference in atomic mass and ionic radius gives rise to mass and strain field fluctuation in the crystal lattice, which enhances the short wavelength phonon scattering and a corresponding reduction in κL [29]. The decrease in crystallite size creates barriers that encourage grain boundary scattering and lower lattice thermal conductivity [10]. The prepared samples have found low lattice thermal conductivity in the low-temperature range of 10–100 K, as shown in Fig. 8c Beyond 100 K, the 6% doped sample has been found to have an increase in the lattice thermal conductivity, in contrast to the inverse relation to the temperature (κL is inversely proportional to T). It has been observed through literature that some materials show deviation from this relation due to alteration in the phase space of phonon scattering. The hardened low-lying and weaker anharmonicity at elevated temperatures contributes to the weak temperature dependence of κL [30].

Seebeck coefficient

Temperature-dependent Seebeck coefficient S(T) of pristine Bi2Se3 and (Bi1−xSbx)2Se2.7Te0.3 samples in the temperature range 10–350 K is presented in Fig. 9. The negative value of S implies that charged Se vacancies operate as electron donors, causing n-type conduction [31]. It is noted that the absolute value of S increases with increasing temperature, presumably attributed to the diffusive contribution of the Seebeck coefficient. The maximum absolute value of about 115 μV/K is obtained for the 2% Sb-doped sample at 350 K (Fig. 8), while higher Sb doping beyond 2% leads to a decrease in S values. Such an observation could be owing to the increased carrier concentration with the co-doping of Sb and Te. The transport properties of charge carriers in (Bi1−xSbx)2Se2.7Te0.3 depend on the variation of x. The observed increase in the Seebeck coefficient of 2% Sb doping can be explained by the asymmetry in the density of states (DOS) near the Fermi level. In thermoelectric material, it is challenging to achieve enhancement in both S and σ simultaneously. Studies show substitution into an anion site would result in an improvement in the effective mass (m*) [1, 32]. Te or S substitution in Se was found to affect the thermoelectric properties by modifying the density of states and the energy band gap at the Fermi level [33]. Therefore, we argue that the isovalent co-doping of Bi2Se3 with Te results in the enhancement of Seebeck coefficient for x = 0.02, where S is reduced with further increase in the Sb content due to increased electron carrier concentration for x = 0.04 and x = 0.06. Theoretical investigation also been done using Boltzmann transport equation and it is well matched with the experimental analysis (see Fig. 9).

Power factor

The carrier concentration significantly impacts electrical conductivity and the Seebeck coefficient, which comprise the power factor (S2σ). Therefore, increasing the Seebeck coefficient without deteriorating electrical conductivity would be the strategy to enhance the power factor in the material [34] [35]. Figure 10 shows the T-dependent power factor for the samples examined. The maximum power factor value of about 3 × 10–4 µW/m K2 at 300 K is obtained for a 2% concentration of Sb, almost 30 times as compared to the pristine Bi2Se3. Using DFT calculations also confirms the maximum power factor at 2% doping of Sb (see Fig. 10b). This is because, in the series of studied samples, (Bi0.98Sb0.02)2Se2.7Te0.3 has the largest Seebeck coefficient due to the co-doping of Te and Sb. Beyond 2% Sb doping, the carrier concentration drastically increases and the Seebeck coefficient decrease, resulting in a reduction in the power factor value of about 2 × 10–4 µW/m K2 (with S ~ − 60 μV/K and ρ ~ 1.0 × 10–5 Ωm) for x = 0.04 and 1.75 × 10–4 µW/m K2 (with S ~ − 80 μV/K and ρ ~ 3.0 × 10–5 Ωm) for x = 0.06.

Figure of merit (ZT)

The dimensionless figure of merit assesses a material’s suitability for use in thermoelectric applications, considering power generation and refrigeration. The competition between electrical transport, represented by the power factor, and thermal transport, characterized by the total thermal conductivity of the material, can be summed up as the figure of merit. Bismuth telluride, with a maximum ZT of approximately 1 near room temperature, is currently the most well-known thermoelectric material. Adding nanoparticles to the host material potentially raise the material’s ZT value by raising the power factor and lowering the lattice thermal conductivity [36]. Figure 11 depicts the temperature-dependent ZT value of the pristine Bi2Se3 and (Bi1−xSbx)2Se2.7Te0.3 systems over the temperature range 10–350 K. With a 2% Sb doping, it is seen a significant increase in the ZT value of around 0.055, almost 27.5 times larger compared to the pristine sample. Therefore, it is concluded that co-doping Sb and Te in Bi2Se3 achieved a satisfactory improvement in the power factor of the material by optimizing the carrier concentration. Further investigation for achieving enhanced ZT by co-doping in bismuth chalcogenides to be considered for the application in refrigeration or other device applications in nanoelectronics or composites employed as light-weight personal and portable devices is in order [37,38,39].

Polycrystalline materials of Bi2Se3 have no preferred direction of orientation due to the multiple grain boundaries present in the material. In such cases, multi-direction thermoelectric measurement studies are preferred. However, due to measurement facility restrictions in-plane measurements of the materials are carried out. Only geometric dimensions are taken into account as there is no option of making connections apart from contacts along the length of the sample was preferred. This is based on the fact that due to anisotropy there would be many quintuples directed along different directions among which some may form an in-plane direction for the test direction. Considering this all thermoelectric parameters are measured by making four-probe contacts along the length of the polycrystalline pellet which would be a direction for current flow in the sample.

All experiments were performed on warming at a rate slower than 20 K/h. The reproducibility of thermoelectric measurements is better than 2%; while, the absolute accuracy of electrical resistivity and thermal conductivity is approximately 10% and 20%, respectively. The error of our Seebeck coefficient measurement is less than 5%. A comparative thermoelectric results of Bi2Se3 compounds prepared using different methods is shown in Table 5.

Conclusions

In this study, we have presented the effect of antimony and tellurium co-dopants on bismuth selenide. It was found that doping enhances the carrier concentration in the material, which in turn increases the electrical conductivity. There was also an advancement in the Seebeck coefficient of the material after incorporating the dopants into the compound. The XRD study confirms the sample belongs to R \(\overline{3 }\) m space group with a rhombohedral structure. Thermal analysis was carried out to examine the thermal stability and melting point of the prepared samples, revealing that the material is stable up to 500 °C for undoped and pertains stability till 250 °C after co-doping which is very well above the working temperature range for the prepared materials. Utilization of both experimental and theoretical analyses enhances the ability to accurately estimate the thermoelectric properties of semiconducting materials. We have utilized this combination to examine the partial density of states, Seebeck coefficient, and power factor by employing the Boltzmann transport equation. Theoretical thermoelectric data were obtained and then compared with experimental results. It was observed that for the 2% doping of Sb, the ZT value was enhanced by almost 28 times compared to the pristine Bi2Se3. Hence, we concluded that Bi2Se3 with co-doping of Sb and Te could be a promising contender for thermoelectric applications.

Data availability

The author confirms that the data supporting the finding will be made available on request through the corresponding author.

References

Musah JD et al (2021) Effective decoupling of seebeck coefficient and the electrical conductivity through isovalent substitution of erbium in bismuth selenide thermoelectric material. J Alloys Compd 857:157559. https://doi.org/10.1016/j.jallcom.2020.157559

Li M et al (2021) Enhanced thermoelectric performance of n-type Bi2Se3 nanosheets through Sn doping. Nanomaterials 11(7):1827. https://doi.org/10.3390/nano11071827

Meroz O, Elkabets N, Gelbstein Y (2020) Enhanced thermoelectric properties of n-Type Bi2Te3-xSex alloys following melt-spinning. ACS Appl Energy Mater 3(3):2090–2095. https://doi.org/10.1021/acsaem.9b02133

Su Z (2009) Improved Thermoelectric performance of P-type polycrystalline Bi2Te3 via hydrothermal treatment with alkali metal salts recommended citation https://tigerprints.clemson.edu/all_dissertations

Liang B, Song Z, Wang M, Wang L, Jiang W (2013) Fabrication and thermoelectric properties of graphene/Bi2Te3 composite materials. J Nanomater 2013(1):210769. https://doi.org/10.1155/2013/210767

Li J, Barry M, Ma Y, Wu A, Chyu MK (2012) Analytical and experimental studies on an innovative composite approach for enhanced thermoelectric performance. AIP Conf Proc 1449(1):69–72. https://doi.org/10.1063/1.4731499

Wang S, Xie W, Li H, Tang X (2011) Enhanced performances of melt spun Bi2(Te, Se)3 for n-type thermoelectric legs. Intermetallics (Barking) 19(7):1024–1031. https://doi.org/10.1016/j.intermet.2011.03.006

Ibrahim EMM, Hakeem AMA, Adam AMM, Shokr EK (2015) Effect of heat treatment on the electrical and thermoelectric properties of Sb doped Bi2Se3. Phys Scr 90(4):045802. https://doi.org/10.1088/0031-8949/90/4/045802

Ryden DJ (1971) A comparison between the transport properties of single crystal, polycrystal and powder anisotropic semiconductors. J Phys C Solid State Phys 4(10):1193–1206. https://doi.org/10.1088/0022-3719/4/10/027

Musah JD et al (2022) Enhanced thermoelectric performance of bulk bismuth selenide: synergistic effect of indium and antimony co-doping. ACS Sustain Chem Eng 10(12):3862–3871. https://doi.org/10.1021/acssuschemeng.1c07256

Hegde GS, Prabhu AN, Huang RY, Kuo YK (2020) Reduction in thermal conductivity and electrical resistivity of indium and tellurium co-doped bismuth selenide thermoelectric system. J Mater Sci Mater Electron 31(22):19511–19525. https://doi.org/10.1007/s10854-020-04383-7

Hegde GS, Prabhu AN, Yang CF, Kuo YK (2022) Reduction in electrical resistivity of bismuth selenide single crystal via Sn and Te co-doping. Mater Chem Phys 278:125675. https://doi.org/10.1016/j.matchemphys.2021.125675

Kulsi C, Kargupta K, Ganguly S, Banerjee D (2017) Enhanced thermoelectric performance of n-type bismuth selenide doped with nickel. Curr Appl Phys 17(12):1609–1615. https://doi.org/10.1016/j.cap.2017.09.004

Suwanboon S, Amornpitoksuk P, Sukolrat A (2011) Dependence of optical properties on doping metal, crystallite size and defect concentration of M-doped ZnO nanopowders (M = Al, Mg, Ti). Ceram Int 37(4):1359–1365. https://doi.org/10.1016/j.ceramint.2010.12.010

Hegde GS, Parol V, Rao A, Prabhu AN, Levinsky JJB, Blake GR (2022) Thermoelectric properties of co-doped (Bi0.98In0.02)2Te2.7Se0.3/reduced graphene oxide composites prepared by solid-state reaction. Mater Res Bull 145:111517. https://doi.org/10.1016/j.materresbull.2021.111517

Ijaz U, Siyar M, Park C (2024) The power of pores: review on porous thermoelectric materials. RSC Sustain 2(4):852–870. https://doi.org/10.1039/d3su00451a

Werner WS (2013) Related titles characterization of surfaces and nanostructures academic and industrial applications characterization of solid materials and heterogeneous catalysts from structure to surface reactivity characterization techniques for polymer nanocomposites basic concepts of X-Ray diffraction advanced characterization techniques for thin film solar cells. http://dnb.d-nb.de

Bohra AK et al (2017) Tellurium-free thermoelectrics: improved thermoelectric performance of n-type Bi2Se3 having multiscale hierarchical architecture. Energy Convers Manag 145:415–424. https://doi.org/10.1016/j.enconman.2017.04.083

Giannozzi P et al (2017) Advanced capabilities for materials modelling with quantum ESPRESSO. J Phys Condens Matter 29(46):465901. https://doi.org/10.1088/1361-648X/aa8f79

Mohyedin MZ et al (2020) Enhanced mechanism of thermoelectric performance of Bi2Se3 using density functional theory. Mater Renew Sustain Energy 9(3):15. https://doi.org/10.1007/s40243-020-00176-4

Tyagi K, Gahtori B, Bathula S, Auluck S, Dhar A (2014) Band structure and transport studies of copper selenide: an efficient thermoelectric material. Appl Phys Lett 105(17):173905. https://doi.org/10.1063/14900927

Madsen GKH, Singh DJ (2006) BoltzTraP. A code for calculating band-structure dependent quantities. Comput Phys Commun 175(1):67–71. https://doi.org/10.1016/j.cpc.2006.03.007

Kim HS, Heinz NA, Gibbs ZM, Tang Y, Kang SD, Snyder GJ (2017) High thermoelectric performance in (Bi0.25Sb0.75)2Te3 due to band convergence and improved by carrier concentration control. Mater Today 20(8):452–459. https://doi.org/10.1016/j.mattod.2017.02.007

Zhao XB, Ji XH, Zhang YH, Zhu TJ, Tu JP, Zhang XB (2005) Bismuth telluride nanotubes and the effects on the thermoelectric properties of nanotube-containing nanocomposites. Appl Phys Lett 86(6):1–3. https://doi.org/10.1063/1.1863440

Drasar C, Klichova I, Koudelka L, Lostak P (1996) Transport coefficients of (Bi1−xSbx)2Se3 single crystals. Cryst Res Technol 31(6):805–812

Shtern M et al (2021) Thermoelectric properties of efficient thermoelectric materials on the basis of bismuth and antimony chalcogenides for multisection thermoelements. J Alloys Compd 877:160328. https://doi.org/10.1016/j.jallcom.2021.160328

Hao F et al (2016) High efficiency Bi2Te3-based materials and devices for thermoelectric power generation between 100 and 300 °C. Energy Environ Sci 9(10):3120–3127. https://doi.org/10.1039/c6ee02017h

Janíček P, Drašar Č, Beneš L, Lošták P (2009) Thermoelectric properties of Tl-doped Bi2Se3 single crystals. Cryst Res Technol 44(5):505–510. https://doi.org/10.1002/crat.200800615

Liu W et al (2013) Studies on the Bi2Te3–Bi2Se3–Bi2S3 system for mid-temperature thermoelectric energy conversion. Energy Environ Sci 6(2):552–560. https://doi.org/10.1039/c2ee23549h

Zhu Y et al (2020) Violation of the T −1 Relationship in the lattice thermal conductivity of Mg3Sb2 with locally asymmetric vibrations. Research 2020:4589786. https://doi.org/10.34133/2020/4589786

Hor YS et al (2009) P-type Bi2 Se3 for topological insulator and low-temperature thermoelectric applications. Phys Rev B Condens Matter Mater Phys 79(19):195208. https://doi.org/10.1103/PhysRevB.79.195208

Devender et al (2016) Harnessing topological band effects in bismuth telluride selenide for large enhancements in thermoelectric properties through isovalent doping. Adv Mater 28(30):6436–6441. https://doi.org/10.1002/adma.201601256

Vaney JB et al (2017) Effect of isovalent substitution on the electronic structure and thermoelectric properties of the solid solution α-As2Te3-xSex (0 ≤ x ≤ 1.5). Inorg Chem 56(4):2248–2257. https://doi.org/10.1021/acs.inorgchem.6b02930

Mao J, Liu Z, Ren Z (2016) Size effect in thermoelectric materials. npj Quantum Mater 1(1):1–9. https://doi.org/10.1038/npjquantmats.2016.28

Dehkordi AM, Zebarjadi M, He J, Tritt TM (2015) Thermoelectric power factor: enhancement mechanisms and strategies for higher performance thermoelectric materials. Mater Sci Eng R Rep 97:1–22. https://doi.org/10.1016/j.mser.2015.08.001

Zhu Q et al (2021) Bottom-up engineering strategies for high-performance thermoelectric materials. Nano-Micro Lett 13(1):119. https://doi.org/10.1007/s40820-021-00637-z

Demirci S, Avazll N, Durgun E, Cahangirov S (2017) Structural and electronic properties of monolayer group III monochalcogenides. Phys Rev B 95(11):115409. https://doi.org/10.1103/PhysRevB.95.115409

Hu Z, Ding Y, Hu X, Zhou W, Yu X, Zhang S (2019) Recent progress in 2D group IV–IV monochalcogenides: synthesis, properties, and applications. Nanotechnology 30(25):252001

Dun C et al (2015) Layered Bi2Se3 nanoplate/polyvinylidene fluoride composite based n-type thermoelectric fabrics. ACS Appl Mater Interfaces 7(13):7054–7059. https://doi.org/10.1021/acsami.5b00514

Sun Y et al (2012) Atomically thick bismuth selenide freestanding single layers achieving enhanced thermoelectric energy harvesting. J Am Chem Soc 134(50):20294–20297. https://doi.org/10.1021/ja3102049

Hegde GS, Prabhu AN, Gao YH, Kuo YK, Reddy VR (2021) Potential thermoelectric materials of indium and tellurium co-doped bismuth selenide single crystals grown by melt growth technique. J Alloys Compd 866:158814. https://doi.org/10.1016/j.jallcom.2021.158814

Zhou Y, Ge Z, Guo J, Feng J (2020) Thermoelectric properties of polycrystalline Bi2Se3−x by powder compaction sintering. Mod Phys Lett B 34(18):2050206. https://doi.org/10.1142/S0217984920502061

Tang H et al (2015) Thermoelectric characterization of individual bismuth selenide topological insulator nanoribbons. Nanoscale 7(15):6683–6690. https://doi.org/10.1039/c5nr00917k

Kadel K, Kumari L, Li WZ, Huang JY, Provencio PP (2011) Synthesis and thermoelectric properties of Bi2Se3 nanostructures. Nanoscale Res Lett 6(1):1–7. https://doi.org/10.1007/s11671-010-9795-7

Acknowledgements

Suchitra Shankar Puthran (SSP) acknowledges Manipal Academy of Higher Education for supporting her financially through the Dr. T. M. A. doctorate fellowship. ANP would like to thank UGC DAE CSR Mumbai for providing the grant UDCSR/MUM/AO/CRS-M-314/2022/12. One of the authors, Ganesh Shridhar Hegde would like to thank Reva University for their support in this collaborative research project. SSP would also like to acknowledge the support and help of her fellow researchers, Mr. Lozil Mendonca, Ms. Mariot Panjikaran, Ms. Manasa Shankar, and Ms. Pramitha A., in analyzing data. The thermoelectric measurements were supported by the National Science and Technology Council of Taiwan under Grant Nos. NSTC 112-2112-M-259-012 (YKK).

Funding

Open access funding provided by Manipal Academy of Higher Education, Manipal.

Author information

Authors and Affiliations

Contributions

Suchitra Puthran contributed to methodology, investigation, and writing—original draft. A N Prabhu contributed to validation, writing—review and editing. Vikash Mishra contributed to DFT calculations. Ganesh Shridhar Hegde contributed to formal analysis. Tzu-Yi Yang contributed to data curation. Y. K. Kuo contributed to data curation and resources.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

I, Suchitra Shankar Puthran, hereby consciously assure that the manuscript is the author’s original work, which has not been published elsewhere.

Additional information

Handling Editor: Scott Beckman.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Puthran, S., Hegde, G.S., Prabhu, A.N. et al. A comprehensive experimental and DFT analysis on thermoelectric properties of Sb, Te co-doped Bi2Se3 polycrystals. J Mater Sci (2024). https://doi.org/10.1007/s10853-024-09865-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10853-024-09865-1