Abstract

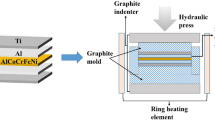

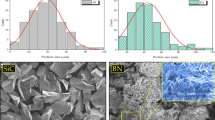

In this paper, B2-FeAl based metal-intermetallic laminate (MIL) composites with and without NiTi shape memory alloy fibers were fabricated by two-step vacuum hot pressing combined with “multi-thin foils” stacking configuration. The microstructure of the composites were studied by scanning electron microscopy and electron backscattered diffraction. Compressive mechanical properties of the composites under quasi-static conditions and high strain rates are investigated via an Instron 5500R load frame and a Split Hopkinson Pressure Bar, respectively. Quasi-static compression stress–strain curves under the strain rate of 10–3/s at 20 °C and dynamic stress–strain curves under the strain rates of 1500/s and 2500/s at 0 °C, 20 °C and 80 °C were obtained, and fracture behavior of the composites were analyzed. The experimental results indicated that the strengths of the composites decreased unexpectedly under high strain rates compared to that under quasi-static condition whether or not NiTi fibers were introduced. Partial phase transition from austenite to ferrite occurred in metal layer during either quasi-static or dynamic compression process. During quasi-static compression, deformation was mainly concentrated in the metal layer. By contrast, metal layers and intermetallic layers exhibit similar deformation capacity during the dynamic loading process, thus, cracks easily appeared in intermetallic layers, causing the premature failure of the composites. Even so, B2-FeAl based MIL composites still possess the best dynamic mechanical properties in the MIL composites family to date. The strength of NiTi fiber reinforced composite is basically higher than that of the counterpart without NiTi fibers at each testing temperature, and fewer microcracks appeared in the intermetallic layer of the former. The reinforcing mechanism was discussed in details.

Graphical abstract

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Lin C, Han Y, Guo C, Chang Y, Han X, Lan L, Jiang F (2017) Synthesis and mechanical properties of novel Ti-(SiCf/Al3Ti) ceramic-fiber-reinforced metal-intermetallic-laminated (CFR-MIL) composites. J Alloys Compd 722:427–437. https://doi.org/10.1016/j.jallcom.2017.06.057

Blessto B, Nair S, Sivaprasad K, Nagarajan D (2021) Simulations on compressive properties of Al-Cu metal intermetallic laminates (MILs) using FEA. Mater Today 41:1110–1115. https://doi.org/10.1016/j.matpr.2020.08.328

Vecchio KS, Jiang F (2016) Fracture toughness of ceramic-fiber-reinforced metallic-intermetallic-laminate (CFR-MIL) composites. MSEA 649:407–416. https://doi.org/10.1016/j.msea.2015.10.018

Thiyaneshwaran N, Selvan CP, Lakshmikanthan A, Sivaprasad K, Ravisankar B (2021) Comparison based on specific strength and density of in-situ Ti/Al and Ti/Ni metal intermetallic laminates. J Mater Res Technol 14:1126–1136. https://doi.org/10.1016/j.jmrt.2021.06.102

Wang Y, Pan H, Wang H (2022) Fabrication and microstructure evolution of B2 structure-based metal-intermetallic-laminate composites. J Alloys Compd 892:162073. https://doi.org/10.1016/j.jallcom.2021.162073

Wu J, Meng L, Jing D, Sun Z, Zhou B, Zhang X (2022) Study on interface and mechanical properties of Ti-Al3Ti metal-intermetallic laminate reinforced by Ni-plated woven carbon fibers. MSEA 833:142554. https://doi.org/10.1016/j.msea.2021.142554

Yuan M, Wang Z, Yao Y, Li L (2019) Finite element analysis of thermal stresses in Ti-Al3Ti metal-intermetallic laminated composites. Results Phys. 15:102706. https://doi.org/10.1016/j.rinp.2019.102706

Sun W, Yang F, Kong F, Wang X, Chen Y (2018) Interface characteristics of Ti6Al4V-TiAl metal-intermetallic laminate (MIL) composites prepared by a novel hot-pack rolling. Mater Charact 144:173–181. https://doi.org/10.1016/j.matchar.2018.07.010

Lin C, Wang S, Yan H, Han Y, Zhu J, Shi H (2020) Optimization mechanisms of microstructure and mechanical properties of SiC fiber reinforced Ti/Al3Ti laminated composite synthesized using titanium barrier. Met Mater Int 27:306–318. https://doi.org/10.1007/s12540-020-00724-7

Liu Y, Wu Z, Liu W, Ma Y, Zhang X, Zhao L, Yang K, Chen Y, Cai Q, Song Y, Liang C (2022) Microstructure evolution and reaction mechanism of continuously compositionally Ti/Al intermetallic graded material fabricated by laser powder deposition. J Mater Res Technol 20:4173–4185. https://doi.org/10.1016/j.jmrt.2022.08.153

Jiao F, Liu M, Jiang F, Zhao J, Li P, Wang Z (2019) Continuous carbon fiber reinforced Ti/Al3Ti metal-intermetallic laminate (MIL) composites fabricated using ultrasonic consolidation assisted hot pressing sintering. MSEA 765:138255. https://doi.org/10.1016/j.msea.2019.138255

Emurlaeva YY, Ivanov IV, Lazurenko DV, Ogneva TS, Chen P, Zhou Q, Bataev AA, Ruktuev AA, Tanaka S, Bataev IA (2021) On the texture and superstructure formation in Ti-TiAl3-Al MIL composites. Intermetallics 135:107231. https://doi.org/10.1016/j.intermet.2021.107231

Son YI, Chung CH, Gowkanapalli RR, Moon CH, Park JS (2015) Kinetics of Fe2Al5 phase formation on 4130 steel by Al pack cementation and its oxidation resistance. Met Mater Int 21:1. https://doi.org/10.1007/s12540-015-1001-0

Wang H, Kou R, Vecchio KS (2020) Design, fabrication and optimization of FeAl-FeAl2 eutectoid metallic-intermetallic laminate (MIL) composites. Materialia 13:100859. https://doi.org/10.1016/j.mtla.2020.100859

Wang Y, Zhou S, Vecchio KS (2016) Annealing effects on the microstructure and properties of an Fe-based metallic-intermetallic laminate (MIL) composite. MS EA 665:47–58. https://doi.org/10.1016/j.msea.2016.04.031

Beygi R, Carbas R, Queiros A, Marques EAS, Shi R, da Silva LFM (2021) Comparative study between stainless steel and carbon steel during dissimilar friction stir welding with aluminum: kinetics of Al-Fe intermetallic growth. Met Mater Int 28:1948–1959. https://doi.org/10.1007/s12540-021-01070-y

Han Y, Que Q, Cheng R, Lin C, Han W, Wang E, Zhu J, Yan H (2021) Microstructure evolution and mechanical performances of SiCf reinforced (Al3Ti + Al3Ni)-based metallic-intermetallic laminate composite. Met Mater Int 27:4035–4046. https://doi.org/10.1007/s12540-020-00942-z

Ogneva TS, Bataev IA, Mali VI, Anisimov AG, Lazurenko DV, Popelyukh AI, Emurlaeva YY, Bataev AA, Tanaka S, Yegoshin KD (2021) Effect of sintering pressure and temperature on structure and properties of Ni-Al metal-intermetallic composites produced by SPS. Mater Charact 180:111415. https://doi.org/10.1016/j.matchar.2021.111415

Sonti KSM, Dash B, Vamsi KV, Bandyopadhyay H, Ravisankar B, Sivaprasad K, Karthikeyan S (2021) Deformation behavior of Al/Cu in-situ metal-intermetallic laminates at low and high strain rates. J Alloys Compd 873:159767. https://doi.org/10.1016/j.jallcom.2021.159767

Cao Y, Guo C, Zhu S, Wei N, Javed RA, Jiang F (2015) Fracture behavior of Ti/Al3Ti metal-intermetallic laminate (MIL) composite under dynamic loading. MSEA 637:235–242. https://doi.org/10.1016/j.msea.2015.04.025

Zhou P, Guo C, Wang E, Wang Z, Chen Y, Jiang F (2016) Interface tensile and fracture behavior of the Ti/Al3Ti metal-intermetallic laminate (MIL) composite under quasi-static and high strain rates. MSEA 665:66–75. https://doi.org/10.1016/j.msea.2016.04.020

Rohatgi A, Harach DJ, Vecchio KS, Harvey KP (2003) Resistance-curve and fracture behavior of Ti-Al3Ti metallic-intermetallic laminate (MIL) composites. Acta Mater 51:2933–2957. https://doi.org/10.1016/S1359-6454(03)00108-3

Li T, Grignon F, Benson DJ, Vecchio KS, Olevsky EA, Jiang F, Rohatgi A, Schwarz RB, Meyers MA (2004) Modeling the elastic properties and damage evolution in Ti-Al3Ti metal-intermetallic laminate (MIL) composites. MSEA 374:10–26. https://doi.org/10.1016/j.msea.2003.09.074

Lin C, Jiang F, Han Y, Wang E, Yuan D, Guo C (2018) Microstructure evolution and fracture behavior of innovative Ti-(SiCf/Al3Ti) laminated composites. J Alloys Compd 743:52–62. https://doi.org/10.1016/j.jallcom.2018.01.392

Han Y, Jiang F, Lin C, Yuan D, Huang H, Wang E, Wang Z, Guo C (2017) Microstructure and mechanical properties of continuous ceramic SiC and shape memory alloy NiTi hybrid fibers reinforced Ti-Al metal-intermetallic laminated composite. J Alloys Compd 729:1145–1155. https://doi.org/10.1016/j.jallcom.2017.09.267

Han Y, Lin C, Han X, Chang Y, Guo C, Jiang F (2017) Fabrication, interfacial characterization and mechanical properties of continuous Al2O3 ceramic fiber reinforced Ti/Al3Ti metal-intermetallic laminated (CCFR-MIL) composite. MSEA 688:338–345. https://doi.org/10.1016/j.msea.2017.02.024

Tian Y, Wang E, Li W, Niu Z, Chang Y, Guo C, Wang Z, Leng Z, Jiang F (2018) Improved fracture toughness of NiTi shape memory alloy fiber-reinforced Ti-Al metal-intermetallic-laminate composite. J Alloys Compd 739:669–677. https://doi.org/10.1016/j.jallcom.2017.12.258

Wang E, Guo C, Zhou P, Lin C, Han X, Jiang F (2016) Fabrication, mechanical properties and damping capacity of shape memory alloy NiTi fiber-reinforced metal-intermetallic-laminate (SMAFR-MIL) composite. Mater Des 95:446–454. https://doi.org/10.1016/j.matdes.2016.01.130

Wang E, Tian Y, Wang Z, Jiao F, Guo C, Jiang F (2017) A study of shape memory alloy NiTi fiber/plate reinforced (SMAFR/SMAPR) Ti-Al laminated composites. J Alloys Compd 696:1059–1066. https://doi.org/10.1016/j.jallcom.2016.12.062

Ding C, Jiang H, Li W, Liu C, Huang H, Liu S, Wei L (2023) Phase transition and damping behavior of Al matrix composites reinforced by a NiTi particle layer. JMS 58:17257–17274. https://doi.org/10.1007/s10853-023-09111-0

Kopaczynska EB, Bednarczyk I, Jablonska M, Niewielski G, Kuc D (2008) The influence of thermo-mechanical treatment on the structure and plasticity of FeAl intermetallic phase-base alloy. Arch Civ Mech Eng 8:15–22. https://doi.org/10.1016/S1644-9665(12)60159-9

Wolski K, Thevenot F, Coze L (1996) Effect of nanometric oxide dispersion on creep resistance of ODS-FeAl prepared by mechanical alloying. Intermetallics 4(4):299–307. https://doi.org/10.1016/0966-9795(95)00053-4

Li M, Wu R, Li T, Yang M, Chang Z, An D, Chen J (2022) Comprehensive understanding of the mechanical properties and microstructure evolution of aluminum alloy/steel laminates during friction stir-assisted incremental forming with synchronous bonding process. MSEA 840:142961. https://doi.org/10.1016/j.msea.2022.142961

Zhou BW, Qi Y, Yi YG, Xu H, Meng LG, Ya B, Jianglin LQ, Zhang XG (2022) Research on the microstructure and properties of iron-based amorphous alloy/Al micro-laminated composites by vacuum hot pressing method. J Non Cryst Solids 576:121287. https://doi.org/10.1016/j.jnoncrysol.2021.121287

Khalid MZ, Friis J, Ninive PH, Marthinsen K, Ringdalen IG, Strandlie A (2021) Modified embedded atom method potential for Fe-Al intermetallics mechanical strength: a comparative analysis of atomistic simulations. Physica B Condens Matter 618:413157. https://doi.org/10.1016/j.physb.2021.413157

Wang H, Harrington T, Zhu C, Vecchio KS (2019) Design, fabrication and characterization of FeAl-based metallic-intermetallic laminate (MIL) composites. Acta Mater 175:445–456. https://doi.org/10.1016/j.actamat.2019.06.039

Wang H, Kou R, Yi H, Figueroa S, Vecchio KS (2021) Mesoscale hetero-deformation induced (HDI) stress in FeAl-based metallic-intermetallic laminate (MIL) composites. Acta Mater 213:116949. https://doi.org/10.1016/j.actamat.2021.116949

Su SL, Rao QH, He YH, Xie W (2020) Effects of porosity on tensile mechanical properties of porous FeAl intermetallics. Trans Nonferrous Met Soc China 30:2757–2763. https://doi.org/10.1016/S1003-6326(20)65418-8

Wang H, Zhu C, Vecchio KS (2020) Deformation and fracture evolution of FeAl-based metallic-intermetallic laminate (MIL) composites. Acta Mater 194:496–515. https://doi.org/10.1016/j.actamat.2020.04.005

Wang Z, Zhang X, Liu M, Zhou Y, Zha Z, Li C, Yang Y, Wang J, Jiang F (2023) Microstructure characterization and mechanical properties of the 304SS-(NiTif/FeAl) metal-intermetallic laminate composites. J Alloys Compd 943:169117. https://doi.org/10.1016/j.jallcom.2023.169117

Thiyaneshwaran N, Sivaprasad K, Ravisankar B, Dash B, Karthikeyan S (2022) Dynamic Compression Behavior of Ti/TiAl3/Al metal intermetallic laminates. J Mater Eng Perform 31:8483–8496. https://doi.org/10.1007/s11665-022-06838-w

Zhou Q, Hu Q, Wang B, Zhou B, Chen P, Liu R (2020) Fabrication and characterization of the Ni-Al energetic structural material with high energy density and mechanical properties. J Alloys Compd 832:154894. https://doi.org/10.1016/j.jallcom.2020.154894

Liu CT, Lee EH, McKamey CG (1989) An environmental effect as the major cause for room-temperature embrittlement in FeAl. Scr Mater 23(6):875–880. https://doi.org/10.1016/0036-9748(89)90263-9

Liu CT, Stringer J, Mundy JN, Horton LL, Angelini P (1997) Ordered intermetallic alloys: an assessment. Intermetallics 5(8):579–596. https://doi.org/10.1016/S0966-9795(97)00045-9

Launey ME, Ritchie RO (2009) On the Fracture Toughness of Advanced Materials. Adv Mater 21:2103–2110. https://doi.org/10.1002/adma.200803322

Kotkunde N, Deole AD, Gupta AK, Singh SK (2014) Comparative study of constitutive modeling for Ti-6Al-4V alloy at low strain rates and elevated temperatures. Mater Des 55:999–1005. https://doi.org/10.1016/j.matdes.2013.10.089

Li YZ, Zhao SL, He SH, Huang CP, Huang MX (2022) Enhancing yield stress and uniform elongation in an ultrathin packaging steel via controlling dislocation density. Int J Plast 155:103334. https://doi.org/10.1016/j.ijplas.2022.103334

Acknowledgements

The authors appreciate the financial support by Outstanding Youth Fund of Heilongjiang Natural Science Foundation (YQ2022E010), the National Natural Sciences Foundation of China (No. 52001084 and 11972128), the Central University Foundation of Harbin Engineering University and Start-up Fund of Heilongjiang Province Postdoctoral Research, Fund of Key Laboratory of Advanced Materials of Ministry of Education No. AdvMat-2023-23 and State Key Laboratory of New Ceramic and Fine Processing Tsinghua University (No. KF202312). The authors also thank Mr. Liu Andong and Mr. Zhang Bohan for their help in terms of sample fabrication.

Funding

Outstanding Youth Fund of Heilongjiang Natural Science Foundation,YQ2022E010,Zhenqiang Wang, the National Natural Sciences Foundation of China, No. 52001084,Zhenqiang Wang,11972128,Zhenqiang Wang, the Central University Foundation of Harbin Engineering University, Start-up Fund of Heilongjiang Province Postdoctoral Research, Fund of Key Laboratory of Advanced Materials of Ministry of Education, No. AdvMat-2023-23, Zhenqiang Wang, State Key Laboratory of New Ceramic and Fine Processing Tsinghua University, No. KF202312, Zhenqiang Wang

Author information

Authors and Affiliations

Contributions

Mengyan Liu: Methodology, Investigation, Writing – review & editing. Xin Zhang: Methodology, Investigation. Zhenqiang Wang: Methodology, Investigation, Formal analysis, Writing – review & editing, Funding acquisition. Chunhuan Guo: Visualization. Yong Yang: Visualization. Fengchun Jiang: Supervision, Visualization, Funding acquisition.

Corresponding authors

Ethics declarations

Conflict of interest

The authors approved the manuscript and the submission of the revised manuscript. There is no conflict of interest among the authors regarding the submission of the revised manuscript for publication.

Ethical approval

Ethics approval was not required for this research.

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, M., Zhang, X., Wang, Z. et al. Compressive mechanical behavior of B2 FeAl-based metal-intermetallic laminate composites. J Mater Sci (2024). https://doi.org/10.1007/s10853-024-09756-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10853-024-09756-5