Abstract

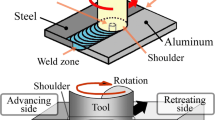

Steel (St) and aluminum (Al) have a high affinity to each other and form intermetallic compounds (IMCs) when bonded by friction stir welding (FSW). Understanding the effect of alloying elements of steel on the formation of IMCs will help to design joints in which the formation of IMCs is controlled. In this study, two kinds of steel, carbon steel (CS) and austenitic stainless steel (SS) with 3 mm thickness, were selected to be welded to aluminum by FSW under similar conditions. The effect of the rotation speed of the FSW tool was also examined in the range of 850–1300 RPM. The morphology, thickness, and composition of IMCs in the interfaces were studied by various characterization techniques. It was observed that the IMC layers in the SS/Al joints were much thinner than the ones in CS/Al joints (0.1–0.7 µm in SS/Al and 2–6 µm in CS/Al). Moreover, the thickness of IMC layer in CS/Al joints increased with increasing the rotation speed while in SS/Al joints it began to decline by exceeding a certain rotation speed. In order to explain these differences, diffusion-based equations were used to calculate the interdiffusion coefficients in both SS/Al and CS/Al couples. It was found that the interdiffusion coefficient in SS/Al was lower than CS/Al. This was attributed to the alloying elements of SS such as Ni and Cr which can diffuse to IMC layer and hinder the growth rate of IMCs. It was also observed that some form of liquation occurred in SS/Al joints at high rotation speed of FSW due to the formation of a low-melting multielement compound of Al–Fe–Cr–Ni. The decline of IMC thickness in SS/Al joints at high rotation speed was attributed to this multielement compound which was melted during FSW and reduced the nucleation rate of Al–Fe IMCs. Finally, the fracture of the specimens and the effect of IMC formation on the joint establishment were elaborated. It was concluded that the alloying elements of steel have a beneficial effect on controlling the growth of IMCs.

Graphic Abstract

Similar content being viewed by others

References

A. Khalkhali, E. Miandoabchi, Thin-Walled Struct. 157, 107089 (2020)

H. Wang, R. Han, Z. Zhang, M. Zhu, L. Liu, Mater. Manuf. Process. 34, 1671 (2019)

L. Shah, M. Ishak, Mater. Manuf. Process. 29, 928 (2014)

Y. Zhou, F. Lan, J. Chen, Thin-Walled Struct. 49, 291 (2011)

Y. Ge, Y. Xia, Thin-Walled Struct. 151, 106759 (2020)

G. Meschut, V. Janzen, T. Olfermann, J. Mater. Eng. Perform. 23, 1515 (2014)

M. Graf, S.P. Sikora, C.S. Roider, Thin-Walled Struct. 130, 286 (2018)

T. Chen, J. Mater. Sci. 44, 2573 (2009)

A.D. D’Souza, S.S. Rao, M.A. Herbert, Met. Mater. Int. 26, 1394 (2020)

H. Amaninia, A. Meysami, A. Foroughifar, Mater. Manuf. Process. 34, 1681 (2019)

P. Gao, Y. Zhang, K.P. Mehta, Met. Mater. Int. 27, 3085 (2021)

R. Beygi, M.Z. Mehrizi, A. Akhavan-Safar, S. Safaei, A. Loureiro, L.F.M. da Silva, Int. J. Adv. Manuf. Tech. 112, 1951 (2021)

B. Seo, K.H. Song, K. Park, Met. Mater. Int. 24, 1232 (2018)

H. Springer, A. Kostka, E. Payton, D. Raabe, A. Kaysser-Pyzalla, G. Eggeler, Acta Mater. 59, 1586 (2011)

M. Pouranvari, Mater. Sci. Technol. 33, 1705 (2017)

R.P. Mahto, S. Anishetty, A. Sarkar, O. Mypati, S.K. Pal, J.D. Majumdar, Met. Mater. Int. 25, 752 (2019)

P. Prangnell, F. Haddadi, Y. Chen, Mater. Sci. Technol. 27, 617 (2011)

S. Madhavan, M. Kamaraj, L. Vijayaraghavan, K. Srinivasa Rao, Mater. Sci. Technol. 33, 200 (2017)

L. Wan, Y. Huang, Int. J. Adv. Manuf. Tech. 99, 1781 (2018)

P. Karakizis, D. Pantelis, D. Dragatogiannis, V. Bougiouri, C. Charitidis, Int. J. Adv. Manuf. Tech. 102, 3065 (2019)

K.P. Mehta, J. Mater. Res. 34, 78 (2019)

R. Beygi, M. Kazeminezhad, A. Kokabi, A. Loureiro, Metal. Mater. Trans. A 46, 2544 (2015)

R. Beygi, M.Z. Mehrizi, D. Verdera, A. Loureiro, J. Mater. Eng. Perform. 255, 739 (2018)

R. Beygi, M.A. Kazeminezhad, A. Kokabi, Trans. Nonferrous Met. Soc. China 22, 2925 (2012)

R. Beygi, M. Kazeminezhad, A. Kokabi, Metal. Mater. Trans. A 45, 361 (2014)

M. Thomä, A. Gester, G. Wagner, M. Fritzsche, Metals 10, 1079 (2020)

P. Kaushik, D.K. Dwivedi, J. Manuf. Process. 68, 198 (2021)

R.P. Mahto, S.K. Pal, J. Manuf. Process. 55, 103 (2020)

B.-S. Sung, H.-S. Bang, S.-O. Jeong, W.-S. Choi, Y.-H. Kwon, H.-S. Bang, Met. Mater. Int. 23, 562 (2017)

F. Liu, P. Dong, Scripta Mater. 191, 167 (2021)

M. Moradi, M.S. Meiabadi, V. Demers, Int. J. Prod. Res. 16, 32 (2021)

A. Wierzbicka-Miernik, K. Miernik, R. Filipek, K. Szyszkiewicz, J. Mater. Sci. 52, 10533 (2017)

K. Zhang, X. Bian, Y. Li, Y. Liu, C. Yang, J. Mater. Res. 28, 3279 (2013)

A.M. Milani, M. Paidar, A. Khodabandeh, S. Nategh, Int. J. Adv. Manuf. Tech. 82, 1495 (2016)

M. Vahdati, M. Moradi, M. Shamsborhan, Trans. Indian Inst. Met. 73, 2587 (2020)

Z. Shen, Y. Chen, M. Haghshenas, A. Gerlich, Eng. Sci. Technol. 18, 270 (2015)

D. Naoi, M. Kajihara, Mater. Sci. Eng. A 459, 375 (2007)

F. Sauer, V. Freise, Z. Elektrochem. 66, 353 (1962)

H. Mehrer, Diffusion in Solids: Fundamentals, Methods, Materials, Diffusion-Controlled Processes (Springer, Verlag Berlin Heidelberg, 2007)

Y. Wei, J. Xiong, J. Li, F. Zhang, S. Liang, Mater. Sci. Technol. 33, 1208 (2017)

J.-O. Andersson, T. Helander, L. Höglund, P. Shi, B. Sundman, Calphad 26, 273 (2002)

C. Dharmendra, S. Shakerin, G.J. Ram, M. Mohammadi, Materialia 13, 100834 (2020)

N. Kulkarni, W. Yuan, R.S. Mishra, Friction Stir Welding of Dissimilar Alloys and Materials (Butterworth-Heinemann, Oxford, 2015)

T. Tanaka, M. Nezu, S. Uchida, T. Hirata, J. Mater. Sci. 55, 3064 (2020)

P. Goel, N.Z. Khan, Z.A. Khan, A. Ahmari, N. Gangil, M.H. Abidi, A.N. Siddiquee, Mater. Manuf. Process. 34, 192 (2019)

Acknowledgements

The authors acknowledge the funding under the reference “UIDP/50022/2020—LAETA—Laboratório Associado de Energia, Transportes e Aeronáutica”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Beygi, R., Carbas, R., Queiros, A. et al. Comparative Study Between Stainless Steel and Carbon Steel During Dissimilar Friction Stir Welding with Aluminum: Kinetics of Al–Fe Intermetallic Growth. Met. Mater. Int. 28, 1948–1959 (2022). https://doi.org/10.1007/s12540-021-01070-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01070-y