Abstract

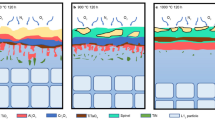

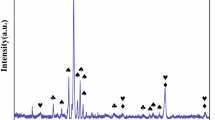

The eutectic high entropy alloys with large amounts of Al and Cr have exhibited superior oxidation resistance. Here, we confirmed that Si could further enhance the oxidation resistance by forming a continuous oxidation layer in Fe36Ni36Al15Cr10Si2Mo1 alloy. Si promoted the outward diffusion and transformation of Al which effectively enhanced the oxidation resistance. The FeCr2O4 spinel and silicate formed by the solid-state reaction also contributed to the oxidation resistance. The thermodynamic and kinetic factors were then discussed to understand the inherent oxidation mechanism of the dual-phase Fe36Ni36Al15Cr10Si2Mo1 alloy, which provide new insights into the dual-phase alloy design and oxidation resistance.

Similar content being viewed by others

Data availability

Data and code related to this study can be obtained from the corresponding author upon reasonable request.

References

Zhang Y, Wu H, Yu X, Tang D (2022) Role of Cr in the high-temperature oxidation behavior of CrXMnFeNi high-entropy alloys at 800 °C in air. Corros Sci 200:110211

He F, Wang Z, Ai C, Li J, Wang J, Kai J (2019) Grouping strategy in eutectic multi-principal-component alloys. Mater Chem Phys 221:138–143

Wang M, Lu Y, Wang T, Zhang C, Cao Z, Li T, Liaw PK (2021) A novel bulk eutectic high-entropy alloy with outstanding as-cast specific yield strengths at elevated temperatures. Scr Mater 204:114132

Wang M, Lu Y, Lan J, Wang T, Zhang C, Cao Z, Li T, Liaw PK (2023) Lightweight, ultrastrong and high thermal-stable eutectic high-entropy alloys for elevated-temperature applications. Acta Mater 248:118806

Yang X, Liu H, Chen B, Ge M, Qian Y, Wang J (2022) Corrosion behavior of GH3535 alloy in molten LiF-BeF2 salt. Corros Sci 199:110168

Garip Y (2022) An investigation on the corrosion performance of Fe2CoCrNi0.5 based high entropy alloys. Corros Sci 206:110497

Garcia-Diaz BL, Olson L, Martinez-Rodriguez M, Fuentes R, Colon-Mercado H, Gray J (2016) High temperature electrochemical engineering and clean energy systems. J South Carol Acad Sci 14:4

Wang YP, Li BS, Ren MX, Yang C, Fu HZ (2008) Microstructure and compressive properties of AlCrFeCoNi high entropy alloy. Mater Sci Eng A 491:154–158

Wu M, Chen K, Xu Z, Li DJW (2020) Effect of Ti addition on the sliding wear behavior of AlCrFeCoNi high-entropy alloy. Wear 462:203493

Yang S, Liu Z, Pi JJML (2020) Microstructure and wear behavior of the AlCrFeCoNi high-entropy alloy fabricated by additive manufacturing. Mater Lett 261:127004

Wu M, Setiawan RC, Li DJW (2022) Benefits of passive element Ti to the resistance of AlCrFeCoNi high-entropy alloy to corrosion and corrosive wear. Wear 492:204231

Wu Q, Wang Z, He F, Yang Z, Li J, Wang J (2022) Endless recrystallization of high-entropy alloys at high temperature. J Mater Sci Technol 128:71–81

Wu Q, Wang Z, Hu X, Zheng T, Yang Z, He F, Li J, Wang JJAM (2020) Uncovering the eutectics design by machine learning in the Al–Co–Cr–Fe–Ni high entropy system. Acta Mater 182:278–286

Jeon SJ, Lee H-C (1992) Effect of copper alloying on the deformation behavior of B2 NiAl intermetallic compounds. In: High temperature aluminides and intermetallics, pp. 392–397. Elsevier

Zhu J, Zhang H, Fu H, Wang A, Li H, Hu Z (2010) Microstructures and compressive properties of multicomponent AlCoCrCuFeNiMox alloys. J Alloy Compd 497:52–56

Dong Y, Lu Y, Kong J, Zhang J, Li T (2013) Microstructure and mechanical properties of multi-component AlCrFeNiMox high-entropy alloys. J Alloy Compd 573:96–101

Nong Z-S, Zhu J-C, Zhao R-D (2017) Prediction of structure and elastic properties of AlCrFeNiTi system high entropy alloys. Intermetallics 86:134–146

Zhu JM, Fu HM, Zhang HF, Wang AM, Li H, Hu ZQ (2010) Microstructures and compressive properties of multicomponent AlCoCrFeNiMoX alloys. Mater Sci Eng A 527:6975–6979

Wu Q, He F, Li J, Kim HS, Wang Z, Wang J (2022) Phase-selective recrystallization makes eutectic high-entropy alloys ultra-ductile. Nat Commun 13:4697

Wang J, Wang Z, Shi X, Liu X, Jia Y, Li J, He F, Wang J (2023) Alloying behavior of W and Mo in the as-cast dual-phase FeNiCrAl multi-component alloys. J Alloy Compd 951:169951

Liu X, Wang J, Shi X, Jia Y, Liu L, Li J, He F, Wang Z, Wang J (2023) Effects of metalloid Si on the microstructure and mechanical properties of Fe36Ni36Cr10Mo1Al17−XSiX alloys. J Alloy Compd 963:171164

Gorr B, Mueller F, Christ HJ, Mueller T, Chen H, Kauffmann A, Heilmaier M (2016) High temperature oxidation behavior of an equimolar refractory metal-based alloy 20Nb–20Mo–20Cr–20Ti–20Al with and without Si addition. J Alloy Compd 688:468–477

Niu Y, Wu Y, Gesmundo FJCS (2006) The oxidation of three Ni–6Si–xAl alloys in 1 atm O2 at 1000 °C. Corros Sci 48:1–22

Wu Y, Gesmundo F, Niu Y (2006) The effect of silicon on the oxidation of a Ni-6 at% Al alloy in 1 atm of pure O2 at 900 °C. Oxid Met 65:53–74

Wang S, Wu Y, Ni CS, Niu Y (2009) The effect of Si additions on the high temperature oxidation of a ternary Ni–10Cr–4Al alloy in 1 atm O2 at 1100 °C. Corros Sci 51:511–517

Chen L, Zhou Z, Tan Z, He D, Bobzin K, Zhao L, Öte M, Königstein T (2018) High temperature oxidation behavior of Al0.6CrFeCoNi and Al0.6CrFeCoNiSi0.3 high entropy alloys. J Alloys Compd 764:845–852

Butler TM, Weaver ML (2016) Oxidation behavior of arc melted AlCoCrFeNi multi-component high-entropy alloys. J Alloy Compd 674:229–244

Laplanche G, Volkert U, Eggeler G, George E (2016) Oxidation behavior of the CrMnFeCoNi high-entropy alloy. Oxid Met 85:629–645

Li Y, Zhang P, Zhang J, Chen Z, Shen B (2021) Oxidation behavior of AlCoCrFeNiSi high-entropy alloys at 1100 °C. Corros Sci 190:109633

Jing Y, Cui X, Liu D, Fang Y, Chen Z, Liu A, Wang X, Jin G (2022) The effects of lattice distortion magnitude on the oxidation performance of laser-cladded NiCoCr–M (M = Al, Fe, Si) multi-principal element alloy coatings under high temperature exposure. Surf Interfaces 33:102305

Kai W, Li CC, Cheng FP, Chu KP, Huang RT, Tsay LW, Kai JJ (2017) Air-oxidation of FeCoNiCr-based quinary high-entropy alloys at 700–900 °C. Corros Sci 121:116–125

Nezakat M, Akhiani H, Penttilä S, Szpunar J (2016) Oxidation behavior of austenitic stainless steel 316L and 310S in air and supercritical water. J Nucl Eng Radiat Sci 2:021008

Wang H, Liang G, Meng C, An X, Wang Y, He X (2023) Technology, A comparative study on the corrosion performance of four FeCrAl alloys with different Cr contents in contact with oxygen-saturated LBE. J Market Res 23:3492–3504

Zhang Y, Zhang G, Yang Q, Cao W, Pu J, Zhu C (2020) Effects of Al sputtering film on the oxidation behavior of NiCrAlY bondcoat. Coatings 10:376

Park SY, Seo D, Kim SW, Kim SE, Hong JK, Lee DBJI (2016) High temperature oxidation of Ti–46Al–6Nb–0.5W–0.5Cr–0.3Si–0.1C alloy. Intermetallics 74:8–14

Zhang Y, Zou D, Wang X, Wang Q, Xu R, Zhang W (2021) Influences of Si content on the high-temperature oxidation behavior of X10CrAlSi18 ferritic heat-resistant stainless steel at 700 °C and 800 °C. Surf Coat Technol 422:127523

Wang H, Liu P, Chen X, Lu Q, Zhou H (2022) Mechanical properties and corrosion resistance characterization of a novel Co36Fe36Cr18Ni10 high-entropy alloy for bioimplants compared to 316L alloy. J Alloy Compd 906:163947

Wagner C (1959) Reaktionstypen bei der Oxydation von Legierungen, Zeitschrift für Elektrochemie, Berichte der Bunsengesellschaft für physikalische. Chemie 63:772–782

Langelier B, Persaud S, Newman R, Botton G (2016) An atom probe tomography study of internal oxidation processes in Alloy 600. Acta Mater 109:55–68

Shen Z, Zhang J, Wu S, Luo X, Jenkins BM, Moody MP, Lozano-Perez S, Zeng X (2022) Microstructure understanding of high Cr–Ni austenitic steel corrosion in high-temperature steam. Acta Mater 226:117634

Shen Z, Tweddle D, Yu H, He G, Varambhia A, Karamched P, Hofmann F, Wilkinson AJ, Moody MP, Zhang L (2020) Microstructural understanding of the oxidation of an austenitic stainless steel in high-temperature steam through advanced characterization. Acta Mater 194:321–336

Shen Z, Chen K, Yu H, Jenkins B, Ren Y, Saravanan N, He G, Luo X, Bagot PA, Moody MP (2020) New insights into the oxidation mechanisms of a Ferritic–Martensitic steel in high-temperature steam. Acta Mater 194:522–539

Chen K, Zhang L, Shen Z (2020) Understanding the surface oxide evolution of T91 ferritic-martensitic steel in supercritical water through advanced characterization. Acta Mater 194:156–167

Ren X, Zhang W, Zhang Y, Zhang P, Liu J (2015) Effects of Fe2O3 content on microstructure and mechanical properties of CaO–Al2O3–SiO2 system. Trans Nonferrous Met Soc China 25:137–145

Du Z, Chen X, Zhang Y, Que X, Liu P, Zhang X, Ma H-L, Zhai MJM (2020) One-pot hydrothermal preparation of Fe3O4 decorated graphene for microwave absorption. Materials 13:3065

Van Der Zaag P, Bloemen P, Gaines J, Wolf R, Van Der Heijden P, Van de Veerdonk R, De Jonge W (2000) On the construction of an Fe3O4-based all-oxide spin valve. J Magn Magn Mater 211:301–308

Limpichaipanit A, Jiansirisomboon S, Tunkasiri T (2017) Sintering temperature-microstructure-property relationships of alumina matrix composites with silicon carbide and silica additives. Sci Eng Compos Mater 24:495–500

Ji C, Li L, Gao W, Wang J, Han JJCI (2023) Influence of Al2O3/SiO2 ratio in multicomponent LNAS glasses and glass-ceramics on the crystallization behavior, microstructure and mechanical performance. Ceram Int 49:10652–10662

Ostovari Moghaddam A, Shaburova NA, Sudarikov MV, Veselkov SN, Samoilova OV, Trofimov EA (2021) High temperature oxidation resistance of Al0.25CoCrFeNiMn and Al0.45CoCrFeNiSi0.45 high entropy alloys. Vacuum 192:110412

Acknowledgements

The work was supported by the National Natural Science Foundation of China (Grant 51874245) and the Natural Science Basic Research Program of Shaanxi (Program No. 2022JC-28).

Author information

Authors and Affiliations

Contributions

The authors confirm their contribution to the paper as follows: XL involved in conceptualization, investigation, writing—original draft, writing—review and editing and visualization. XS involved in methodology, validation and data curation. JW involved in formal analysis and writing—review and editing. YJ involved in methodology and writing—review and editing. ZW involved in supervision, project administration, writing—review and editing and funding acquisition. FH, JL and JW involved in supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not applicable.

Additional information

Handling Editor: Zhao Shen.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, X., Shi, X., Wang, J. et al. Enhancing oxidation resistance with Si in Fe36Ni36Al15Cr10Si2Mo1 multi-principal element alloy at 700 °C. J Mater Sci 59, 10444–10460 (2024). https://doi.org/10.1007/s10853-024-09752-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09752-9