Abstract

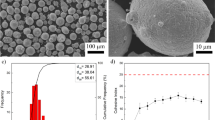

The regulation of hydrogen content in the continuous casting process is conducive to the reduction of pore defects in the casting billet. In this paper, the influence of negative pressure (NP) and continuous casting speed (CCS) on hydrogen content in copper rod billet prepared by negative pressure continuous casting (NPCC) technique was analyzed, and the mechanism of the coordinated coupling of NP and melt flow on hydrogen removal was revealed. It is clarified that with the CCS of 20 mm min−1 and an increase in the NP value from − 20 to − 80 kPa, the hydrogen content is reduced from 1.0 to 0.3 ppm. The coordinated action of NP and melt flow induced by CCS can minimize the hydrogen content. When the NP value is − 80 kPa and the CCS is 10 mm min−1, the hydrogen content is as low as 0.2 ppm, and the hydrogen removal rate is 85.7%. The larger the NP, the smaller the critical nucleation radius of the hydrogen bubble, and the larger the growth rate of the hydrogen bubble. The coupling of the NP field and flow field can make the melt which is difficult to nucleate and grow of the hydrogen bubble flow to the position which is easy to nucleate and grow. The effect of the vortex fields in the purification chamber on the removal of hydrogen is not affected by the CCS, but the CCS affects the floating of hydrogen at the solidification front, which leads to a small increase in the hydrogen content with the increase of the CCS. Our study provides a theoretical basis for the preparation of high-quality metal billets.

Similar content being viewed by others

References

Wei BX, Xu J, Frank Cheng Y et al (2021) Microstructural response and improving surface mechanical properties of pure copper subjected to laser shock peening. Appl Surf Sci 564:150336

Zhang DQ, Lu JM, Shi C et al (2021) Anti-corrosion performance of covalent layer-by-layer assembled films via click chemistry reaction on the copper surface. Corros Sci 178:109063

Nobakht S, Kazeminezhad M (2017) Electrical annealing of severely deformed copper: microstructure and hardness. Int J Miner Metall Mater 24(10):1158–1168

Li JW, Pu Y (2015) Application of ultrasonic treating to degassing of commercially pure copper melt: a preliminary investigation. Mater Lett 161:60–63

Karagadde S, Sundarraj S, Dutta P (2009) Modeling growth of hydrogen bubbles in aluminum castings using the level-set method. Scripta Mater 61(2):216–219

Luo L, Luo LS, Su YQ et al (2021) Reducing porosity and optimizing performance for Al-Cu-based alloys with large solidification intervals by coupling travelling magnetic fields with sequential solidification. J Mater Sci Technol 79:1–14

Dong XX, Zhu XZ, Ji SX (2019) Effect of super vacuum assisted high pressure die casting on the repeatability of mechanical properties of Al-Si-Mg-Mn die-cast alloys. J Mater Process Technol 266:105–113

Hu C, Zhao HD, Wang XL et al (2020) Microstructure and properties of AlSi12Fe alloy high pressure die-castings under different vacuum levels. Vacuum 180:109561

Maire E, Zhou SX, Adrien J et al (2011) Damage quantification in aluminium alloys using in situ tensile tests in X-ray tomography. Eng Fract Mech 78(15):2679–2690

Ghahremaninezhad A, Ravi-Chandar K (2013) Ductile failure behavior of polycrystalline Al 6061–T6 under shear dominant loading. Int J Fract 180(1):23–39

Johansen ST, Graadahl S, Hagelien TF (2004) Entrainment of inclusions from the dross in stirred reactors for melt treatment. Appl Math Model 28(1):63–77

Tsai D, Hsu M, Hwang W et al (2010) Mathematical modeling of solidification microstructure of pure copper by vacuum continuous casting and its experimental verification. ISIJ Int 50(12):1843–1850

Tsai DC, Hwang WS, Jiang CS (2009) Numerical simulation of solidification morphologies of pure copper by vacuum continuous casting using cellular automaton model and its experimental verification. Int J Cast Met Res 22(1–4):135–138

Wan H, Xu B, Yang B et al (2020) The impurities distribution and purification efficiency of high-purity aluminum preparation by zone melting in vacuum. Vacuum 171:108839

Banganayi C, Nyembwe K, Mageza K (2020) Annealer curve characteristics of electrolytically refined tough pitch copper (Cu-ETP) and oxygen free up-cast copper (Cu-OF) for electrical cable wires. Results Mater 8:100146

Yuan DW, Yang B, Chen JS et al (2017) Upward continuous casting in the manufacture of Cu-Cr-Ag alloys: potential for enhancing strength whilst maintaining ductility. Metall Mater Trans A 48(12):6083–6090

Zhou BW, Yin SJ, Tang RH et al (2016) Study on fabrication of bulk metallic glassy composites by horizontal continuous casting method. J Alloy Compd 660:39–43

You BS, Yim CD, Kim SH (2005) Solidification of AZ31 magnesium alloy plate in a horizontal continuous casting process. Mater Sci Eng, A 413–414:139–143

Zhang LW, Wang ZL, Xu CJ et al (2019) A vertical continuous casting machine for large blooms. Ironmak Steelmak 46(8):742–746

Liao WN, Liu XF, Yang YH et al (2019) Relationship and mechanism between microstructure and property of C70250 copper alloy strip prepared by temperature controlled mold continuous casting. Mater Sci Eng, A 767:138428

Su YJ, Liu XH, Wu YF et al (2013) Numerical simulation of temperature field in horizontal core-filling continuous casting for copper cladding aluminum rods. Int J Miner Metall Mater 20(7):684–692

Ba QN, Liu XF, Liao WN (2023) Effect of negative pressure continuous casting on hydrogen escape behavior in pure copper melt and purification mechanism. Int Commun Heat Mass Transfer 140:106565

Ba QN, Liu XF, Yang YH et al (2022) Motion behavior and removal mechanism of inclusions during negative pressure continuous casting process. J Mater Sci 57(46):21502–21518. https://doi.org/10.1007/s10853-022-07950-x

Pitkälä J, Holappa L, Jokilaakso A (2024) Nitrogen control in production of N-alloyed stainless steels in AOD converter: application of Sieverts’ law. Metall and Mater Trans B 55(1):524–536

Li KW, Liu JH, Zhang J et al (2017) Theoretical analysis of bubble nucleation in molten steel supersaturated with nitrogen or hydrogen. Metall and Mater Trans B 48(4):2136–2146

Verhaart HFA, De Jonge RM, Van Stralen SJD (1980) Growth rate of a gas bubble during electrolysis in supersaturated liquid. Int J Heat Mass Transf 23(3):293–299

Magnusson H, Frisk K (2017) Diffusion, permeation and solubility of hydrogen in copper. J Phase Equilib Diffus 38(1):65–69

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51974027, U1703131).

Author information

Authors and Affiliations

Contributions

Qinan Ba: Methodology, Writing-Original draft, Conceptualization, Formal analysis, Writing-Review & Editing, Visualization. Xuefeng Liu: Conceptualization, Validation, Supervision. Writing-Review & Editing, Funding acquisition. Yaohua Yang: Visualization, Investigation. Ligui Gai: Visualization, Investigation.

Corresponding author

Ethics declarations

Conflict of interest

We declare that all authors have no conflict of interest.

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ba, Q., Liu, X., Yang, Y. et al. Influence and regulation of hydrogen content in pure copper rod billet during negative pressure continuous casting process. J Mater Sci (2024). https://doi.org/10.1007/s10853-024-09747-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10853-024-09747-6