Abstract

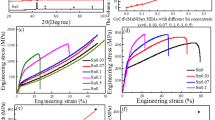

This study fabricated four kinds of CoCrMnFeNiX0.1 (X = Al, Cu, Mo, Ti) high-entropy alloys through rolling with subsequent thermal treatment, to investigate the alloying effects on the microstructural evolution, mechanical properties, and electrochemical corrosion performance. High-density parallel twinning bands were observed in the as-rolled CoCrMnFeNiX0.1 alloys, excluding the Cu0.1 variant, signifying that plastic deformation was dominated by twinning. However, detwinning and thickening of twin layers was observed after annealing. This effect was more pronounced in the rolling direction-normal direction (RD-ND) plane due to the stress state induced by rolling. The introduction of Cu altered the deformation mechanism to a combination of twinning and slipping, resulting in fewer twinning bands. Notably, annealing induced the formation of abundant bamboo-shaped twinning bands (width: ~ 10 nm) in the Cu0.1 alloy, which were correlated with nano precipitated particles. Additionally, the incorporation of Mo or Al elements activated more twinning directions, thereby enhancing plasticity. For the Ti0.1 alloy, the primary factors influencing the altered tensile and electrochemical performances were the formation and growth of few precipitated particles during annealing. Consequently, the strengthening effect can be ranked in the order of Mo > Ti > Al > Cu. Therefore, the addition of Al and Ti is recommended for improving the anticorrosive property and thermal stability of recrystallized grains.

Graphical Abstract

Similar content being viewed by others

Data and code availability

No new data were created or analyzed in this study. Data will be available to readers from the corresponding author upon reasonable request.

References

Yeh J-W, Chen S-K, Lin S-J, Gan J-Y, Chin T-S, Shun T-T, Tsau C-H, Chang S-Y (2004) Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater 6:299–303. https://doi.org/10.1002/adem.200300567

Cantor B, Chang ITH, Knight P, Vincent AJB (2004) Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng A 375–377:213–218. https://doi.org/10.1016/j.msea.2003.10.257

Lyu Z, Fan X, Lee C, Wang S-Y, Feng R, Liaw PK (2018) Fundamental understanding of mechanical behavior of high-entropy alloys at low temperatures: a review. J Mater Res 33:2998–3010. https://doi.org/10.1557/jmr.2018.273

He XY, Wang H, Zhu ZG, Wang LZ, Liu JQ, Haghdadi N, Nai SML, Huang J, Primig S, Ringer SP, Liao XZ (2022) Texture evolution in a CrMnFeCoNi high-entropy alloy manufactured by laser powder bed fusion. J Mater Sci 57:9714–9725. https://doi.org/10.1007/s10853-022-07025-x

Zhang Y, Zuo TT, Tang Z, Gao MC, Dahmen KA, Liaw PK, Lu ZP (2014) Microstructures and properties of high-entropy alloys. Prog Mater Sci 61:1–93. https://doi.org/10.1016/j.pmatsci.2013.10.001

Laplanche G, Kostka A, Horst OM, Eggeler G, George EP (2016) Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy. Acta Mater 118:152–163. https://doi.org/10.1016/j.actamat.2016.07.038

Gao X, Chen R, Liu T, Fang H, Qin G, Su Y, Guo J (2022) High-entropy alloys: a review of mechanical properties and deformation mechanisms at cryogenic temperatures. J Mater Sci 57:6573–6606. https://doi.org/10.1007/s10853-022-07066-2

Wu Z, Parish CM, Bei H (2015) Nano-twin mediated plasticity in carbon-containing FeNiCoCrMn high entropy alloys. J Alloys Compd 647:815–822. https://doi.org/10.1016/j.jallcom.2015.05.224

He JY, Liu WH, Wang H, Wu Y, Liu XJ, Nieh TG, Lu ZP (2014) Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater 62:105–113. https://doi.org/10.1016/j.actamat.2013.09.037

Kumar J, Linda A, Sadhasivam M, Pradeep KG, Gurao NP, Biswas K (2022) The effect of Al addition on solid solution strengthening in CoCrFeMnNi: experiment and modelling. Acta Mater 238:118208. https://doi.org/10.1016/j.actamat.2022.118208

Xie J, Dong H, Hao Y, Fan Z, Wang C-A (2021) Exploring the formation mechanism of deformation twins in CrMnFeCoNi high entropy alloy. Acta Metall Sin 35:1275–1280. https://doi.org/10.1007/s40195-021-01362-7

Maier-Kiener V, Schuh B, George EP, Clemens H, Hohenwarter A (2017) Insights into the deformation behavior of the CrMnFeCoNi high-entropy alloy revealed by elevated temperature nanoindentation. J Mater Res 32:2658–2667. https://doi.org/10.1557/jmr.2017.260

Huang S, Li W, Lu S, Tian F, Shen J, Holmström E, Vitos L (2015) Temperature dependent stacking fault energy of FeCrCoNiMn high entropy alloy. Scr Mater 108:44–47. https://doi.org/10.1016/j.scriptamat.2015.05.041

Zaddach AJ, Scattergood RO, Koch CC (2015) Tensile properties of low-stacking fault energy high-entropy alloys. Mater Sci Eng A 636:373–378. https://doi.org/10.1016/j.msea.2015.03.109

Sun SJ, Tian YZ, Lin HR, Lu S, Yang HJ, Zhang ZF (2019) Modulating the prestrain history to optimize strength and ductility in CoCrFeMnNi high-entropy alloy. Scr Mater 163:111–115. https://doi.org/10.1016/j.scriptamat.2019.01.012

Sathiaraj GD, Bhattacharjee PP, Tsai C-W, Yeh J-W (2016) Effect of heavy cryo-rolling on the evolution of microstructure and texture during annealing of equiatomic CoCrFeMnNi high entropy alloy. Intermetallics 69:1–9. https://doi.org/10.1016/j.intermet.2015.10.005

Picak S, Yilmaz HC, Karaman I (2021) Simultaneous deformation twinning and martensitic transformation in CoCrFeMnNi high entropy alloy at high temperatures. Scr Mater 202:113995. https://doi.org/10.1016/j.scriptamat.2021.113995

Bhattacharjee PP, Sathiaraj GD, Zaid M, Gatti JR, Lee C, Tsai C-W, Yeh J-W (2014) Microstructure and texture evolution during annealing of equiatomic CoCrFeMnNi high-entropy alloy. J Alloys Compd 587:544–552. https://doi.org/10.1016/j.jallcom.2013.10.237

Sun SJ, Tian YZ, Lin HR, Wang ZJ, Zhang ZF (2021) Revisiting the role of prestrain history in the mechanical properties of ultrafine-grained CoCrFeMnNi high-entropy alloy. Mater Sci Eng A 801:140398. https://doi.org/10.1016/j.msea.2020.140398

Moon J, Bouaziz O, Kim HS, Estrin Y (2021) Twinning engineering of a CoCrFeMnNi high-entropy alloy. Scr Mater 197:113808. https://doi.org/10.1016/j.scriptamat.2021.113808

Kong D, Guo J, Liu R, Zhang X, Song Y, Li Z, Guo F, Xing X, Xu Y, Wang W (2019) Effect of remelting and annealing on the wear resistance of AlCoCrFeNiTi0.5 high entropy alloys. Intermetallics 114:106560. https://doi.org/10.1016/j.intermet.2019.106560

Shun T-T, Chang L-Y, Shiu M-H (2012) Microstructure and mechanical properties of multiprincipal component CoCrFeNiMox alloys. Mater Charact 70:63–67. https://doi.org/10.1016/j.matchar.2012.05.005

Yeh J-W, Lin S-J, Chin T-S, Gan J-Y, Chen S-K, Shun T-T, Tsau C-H, Chou S-Y (2004) Formation of simple crystal structures in Cu–Co–Ni–Cr–Al–Fe–Ti–V alloys with multiprincipal metallic elements. Metall Mater Trans A 35:2533–2536. https://doi.org/10.1007/s11661-006-0234-4

Kang J, Park N, Kim J-K, Park JH (2021) Role of recrystallization and second phases on mechanical properties of (CoCrFeMnNi)95.2Al3.2Ti1.6 high entropy alloy. Mater Sci Eng A 814:141249. https://doi.org/10.1016/j.msea.2021.141249

Tang L, Guo M, Zhou Y, Wang N (2023) Effects of trace secondary elements on microstructure and properties in CoCrMnFeNiX0.1 alloys. J Mater Res 38:3110–3123. https://doi.org/10.1557/s43578-023-01031-8

Hou J, Qiao J, Lian J, Liaw PK (2021) Revealing the relationship between microstructures, textures, and mechanical behaviors of cold-rolled Al0.1CoCrFeNi high-entropy alloys. Mater Sci Eng A 804:140752. https://doi.org/10.1016/j.msea.2021.140752

Huang X, Hansen N, Tsuji N (2006) Hardening by annealing and softening by deformation in nanostructured metals. Science 312:249–251. https://doi.org/10.1126/science.1124268

Gu J, Song M (2019) Annealing-induced abnormal hardening in a cold rolled CrMnFeCoNi high entropy alloy. Scr Mater 162:345–349. https://doi.org/10.1016/j.scriptamat.2018.11.042

Fu W, Gan K, Huang Y, Ning Z, Sun J, Cao F (2021) Elucidating the transition of cryogenic deformation mechanism of CrMnFeCoNi high entropy alloy. J Alloys Compd 872:159606. https://doi.org/10.1016/j.jallcom.2021.159606

Klimova MV, Shaysultanov DG, Zherebtsov SV, Stepanov ND (2019) Effect of second phase particles on mechanical properties and grain growth in a CoCrFeMnNi high entropy alloy. Mater Sci Eng A 748:228–235. https://doi.org/10.1016/j.msea.2019.01.112

Huang T-H, Hsueh C-H (2021) Microstructures and mechanical properties of (CoCrFeMnNi)100-Mo high entropy alloy films. Intermetallics 135:107236. https://doi.org/10.1016/j.intermet.2021.107236

Li N, Gu J, Gan B, Qiao Q, Ni S, Song M (2020) Effects of Mo-doping on the microstructure and mechanical properties of CoCrNi medium entropy alloy. J Mater Res 35:2726–2736. https://doi.org/10.1557/jmr.2020.256

Shahmir H, Nili-Ahmadabadi M, Shafiee A, Andrzejczuk M, Lewandowska M, Langdon TG (2018) Effect of Ti on phase stability and strengthening mechanisms of a nanocrystalline CoCrFeMnNi high-entropy alloy. Mater Sci Eng A 725:196–206. https://doi.org/10.1016/j.msea.2018.04.014

Beyramali Kivy M, Asle Zaeem M (2017) Generalized stacking fault energies, ductilities, and twinnabilities of CoCrFeNi-based face-centered cubic high entropy alloys. Scr Mater 139:83–86. https://doi.org/10.1016/j.scriptamat.2017.06.014

Schneider M, Couzinié J-P, Shalabi A, Ibrahimkhel F, Ferrari A, Körmann F, Laplanche G (2024) Effect of stacking fault energy on the thickness and density of annealing twins in recrystallized FCC medium and high-entropy alloys. Scr Mater 240:115844. https://doi.org/10.1016/j.scriptamat.2023.115844

Wang Z (2004) Cyclic deformation response of planar-slip materials and a new criterion for the wavy-to-planar-slip transition. Philos Mag 84:351–379. https://doi.org/10.1080/14786430310001639824

Leffers T, Ray RK (2009) The brass-type texture and its deviation from the copper-type texture. Prog Mater Sci 54:351–396. https://doi.org/10.1016/j.pmatsci.2008.09.002

Wang ZY, Han D, Li XW (2017) Competitive effect of stacking fault energy and short-range clustering on the plastic deformation behavior of Cu-Ni alloys. Mater Sci Eng, A 679:484–492. https://doi.org/10.1016/j.msea.2016.10.064

Acknowledgements

The authors would like to acknowledge the financial support of the National Natural Science Foundation of China (No. 51801072, 51805219), and China Postdoctoral Science Foundation (2019TQ0126).

Funding

Innovative Research Group Project of the National Natural Science Foundation of China (No. 51801072, 51805219), China Postdoctoral Science Foundation (2019TQ0126).

Author information

Authors and Affiliations

Contributions

LT contributed to conceptualization, provided methodology, funding acquisition, supervision, writing review and editing. YZ wrote the original manuscript, carried out SEM and TEM observations and analyses, performed polarization curve tests and annealing treatment. SW performed tensile experiments and edited the manuscript. NL was contributed to resources, supervision and data analysis. PC performed rolling experiment and data analysis. NW provided resources and funding acquisition, supervised and edited the manuscript. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not applicable.

Additional information

Handling Editor: Zhao Shen.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tang, L., Zhou, Y., Wang, S. et al. Alloying effects on the microstructure and properties of CoCrFeMnNiX0.1 high-entropy alloys via rolling and thermal treatment. J Mater Sci 59, 7529–7546 (2024). https://doi.org/10.1007/s10853-024-09639-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09639-9